Comprehending Flexible Thin Film Temperature Sensor Technology

The Science Behind Flexible Thin Film Sensors

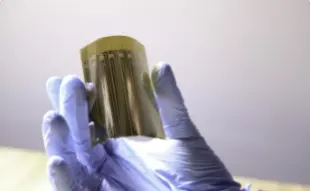

Flexible thin film temperature sensors represent a pinnacle of modern sensor technology. These devices are fabricated using advanced deposition techniques, typically involving the application of temperature-sensitive materials onto a flexible substrate. The core of these sensors often consists of materials like platinum or nickel, chosen for their stable and predictable resistance changes in response to temperature fluctuations.

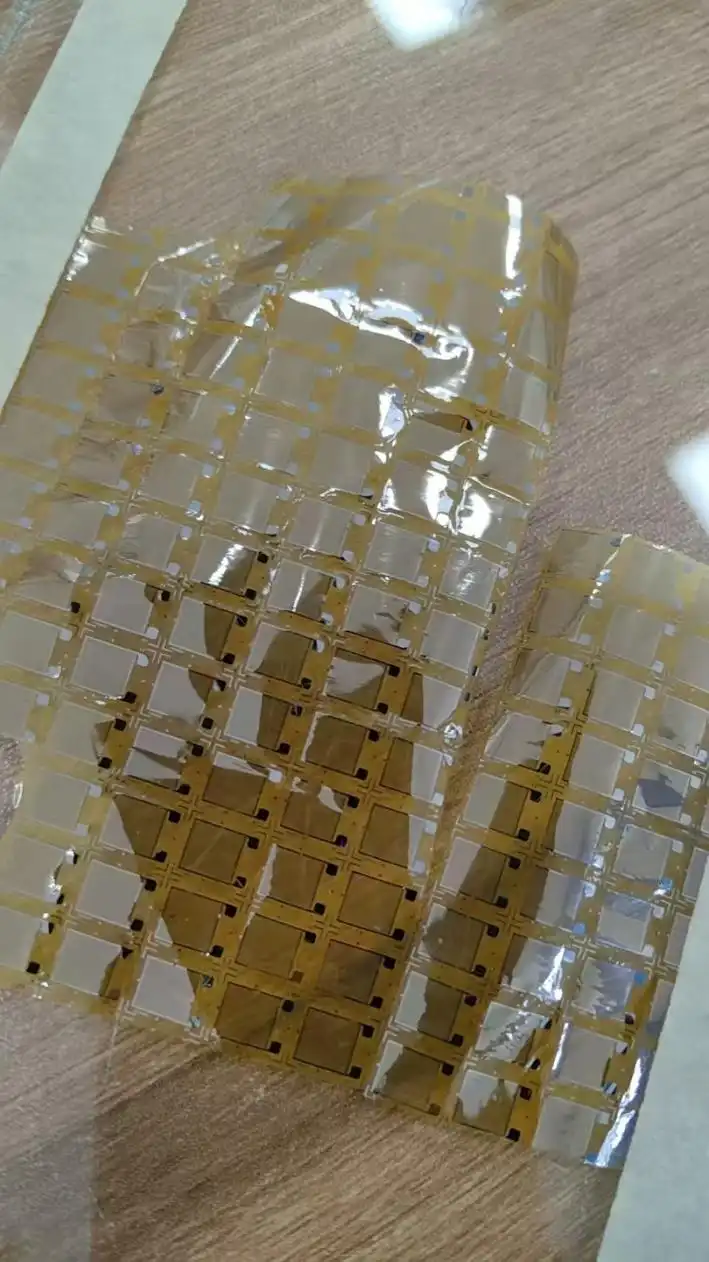

The manufacturing process involves precision layering of conductive and insulating materials, creating a sensor that's not only incredibly thin but also highly responsive to temperature changes. This layered structure allows for excellent thermal coupling with the measured surface, ensuring rapid and accurate temperature readings.

Key Components and Design Features

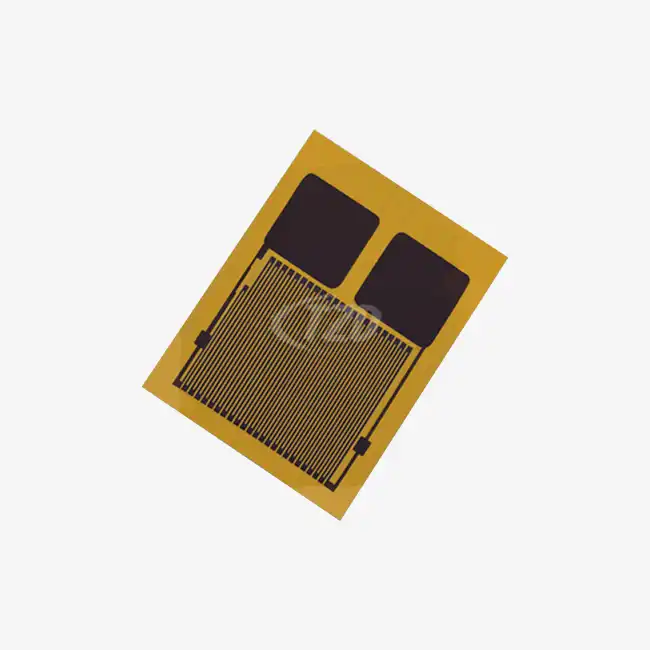

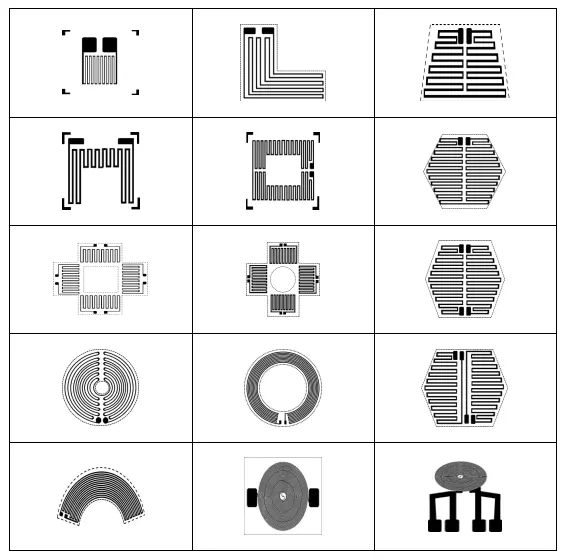

The design of flexible thin film temperature sensors is a testament to engineering ingenuity. These sensors typically comprise several key components:

1. Substrate: A flexible, thermally stable material that serves as the foundation.

2. Sensing Element: Usually a thin metal film with a known temperature coefficient of resistance.

3. Protective Layer: A coating that shields the sensing element from environmental factors.

4. Connection Pads: Areas for electrical connections to measurement circuits.

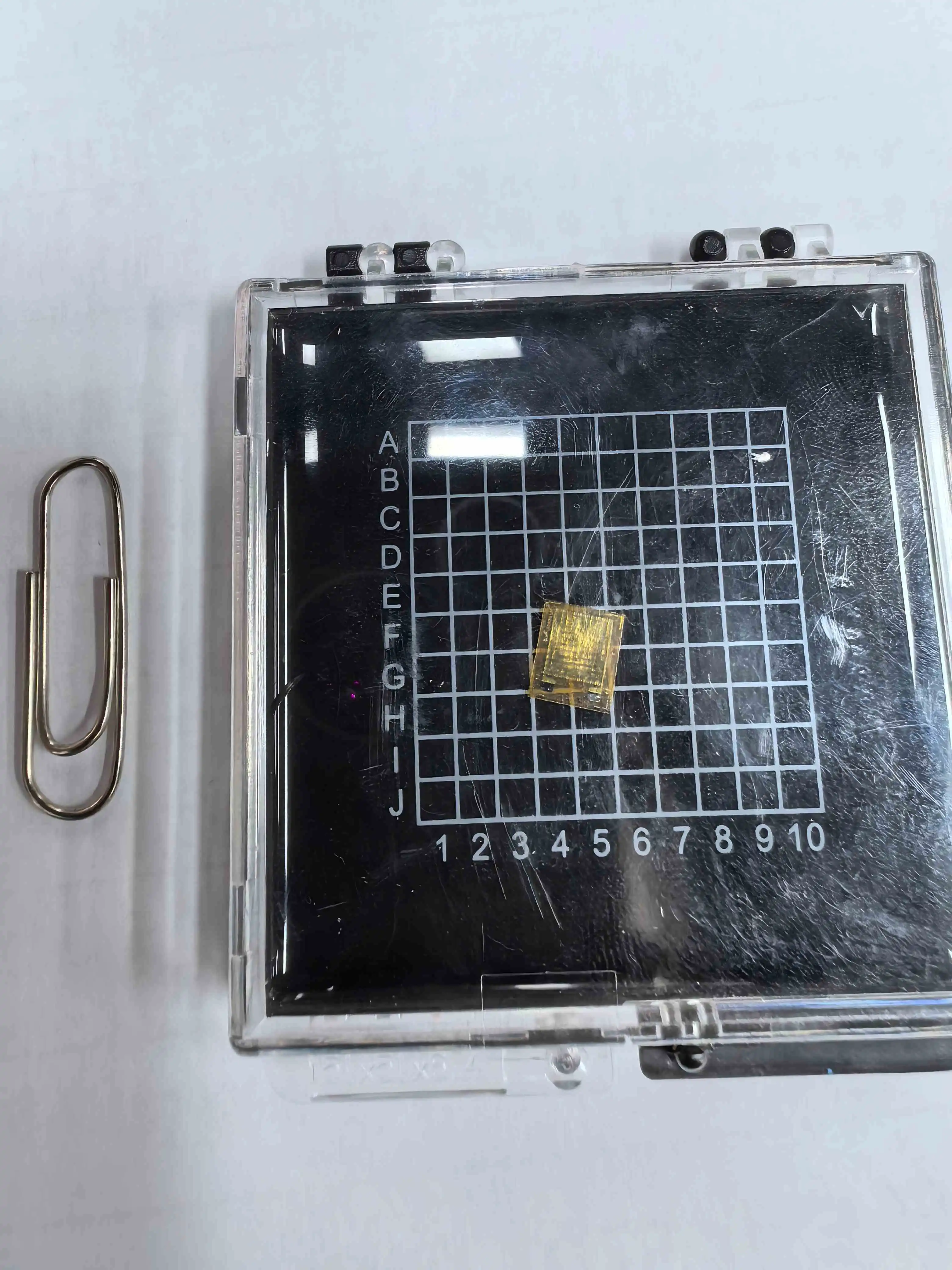

The dimensions of these sensors can be remarkably small, with some designs measuring as little as 7mm x 5mm x 0.05mm. This compact size allows for integration into spaces where traditional sensors simply cannot fit. Moreover, the design is often customizable, allowing manufacturers to tailor sensors to specific application requirements.

Comparison with Traditional Temperature Sensors

When compared to traditional temperature sensors like thermocouples or bulky RTDs (Resistance Temperature Detectors), flexible thin film sensors offer several distinct advantages:

1. Size and Weight: Significantly smaller and lighter, reducing impact on the measured system.

2. Response Time: Much faster response to temperature changes due to their minimal thermal mass.

3. Surface Conformity: Ability to adhere to curved or irregular surfaces, enhancing thermal contact.

4. Accuracy: Capable of high precision, with some models achieving Class A (±0.6°C) or Class B (±1.2°C) accuracy.

5. Temperature Range: Wide operating range, typically from -70°C to +200°C, suitable for diverse applications.

These comparative advantages make flexible thin film temperature sensors the preferred choice in many cutting-edge applications where space is at a premium and accuracy is paramount.

Applications and Industries Benefiting from Flexible Thin Film Temperature Sensors

Aerospace and Aviation

In the aerospace industry, where precision and reliability are non-negotiable, flexible thin film temperature sensors have found numerous critical applications. These sensors are instrumental in monitoring engine temperatures, ensuring optimal performance and safety of aircraft systems. Their ability to conform to the curved surfaces of aircraft components makes them ideal for measuring skin temperatures during flight, providing crucial data for thermal management systems.

Moreover, these sensors play a vital role in ice detection systems on aircraft wings, helping to prevent dangerous ice accumulation. The sensors' rapid response time allows for immediate detection of temperature changes, enabling swift action to maintain safe flying conditions. In spacecraft and satellites, where every gram matters, the lightweight nature of these sensors is particularly advantageous, allowing for comprehensive temperature monitoring without significantly impacting payload weight.

Medical and Healthcare Devices

The medical field has embraced flexible thin film temperature sensors for their accuracy and non-invasive nature. These sensors are incorporated into a variety of medical devices, from simple digital thermometers to sophisticated diagnostic equipment. Their flexibility and thin profile make them ideal for wearable health monitoring devices, allowing for continuous patient temperature monitoring without causing discomfort.

In more advanced applications, these sensors are used in medical imaging equipment, ensuring optimal operating temperatures for sensitive components. They're also crucial in thermal ablation procedures, where precise temperature control is essential for effective treatment. The biocompatibility of materials used in these sensors makes them suitable for applications involving direct contact with the skin or for use in minimally invasive medical procedures.

Automotive and Transportation

The automotive industry leverages flexible thin film temperature sensors in numerous ways to enhance vehicle performance and safety. These sensors are crucial components in engine management systems, monitoring coolant and oil temperatures to prevent overheating and ensure optimal engine efficiency. Their ability to withstand harsh environments makes them suitable for placement in various parts of a vehicle, from the engine bay to the exhaust system.

In electric and hybrid vehicles, these sensors play a critical role in battery thermal management. They help maintain optimal battery temperature, which is essential for maximizing battery life and performance. Additionally, these sensors are used in climate control systems, providing accurate cabin temperature readings for passenger comfort. In the realm of autonomous vehicles, flexible thin film temperature sensors contribute to the thermal management of sensitive electronic components, ensuring reliable operation of advanced driver assistance systems.

Advancements and Future Trends in Flexible Thin Film Temperature Sensor Technology

Emerging Materials and Fabrication Techniques

The field of flexible thin film temperature sensors is experiencing rapid advancements in materials science and fabrication techniques. Researchers are exploring novel materials with enhanced temperature sensitivity and stability. Graphene and carbon nanotubes are at the forefront of this research, promising even thinner sensors with superior thermal conductivity and electrical properties.

Advanced fabrication techniques like roll-to-roll processing are being developed to enable large-scale, cost-effective production of these sensors. This method allows for continuous manufacturing of flexible sensors on long rolls of substrate, significantly reducing production costs and increasing accessibility. Additionally, 3D printing technologies are being adapted to create custom-designed sensors with complex geometries, opening up new possibilities for application-specific sensor designs.

Integration with IoT and Smart Systems

The integration of flexible thin film temperature sensors with Internet of Things (IoT) technologies is revolutionizing data collection and analysis. These sensors, when coupled with wireless communication modules, can transmit real-time temperature data to cloud-based platforms. This integration enables continuous monitoring, predictive maintenance, and data-driven decision-making across various industries.

In smart buildings, for instance, these sensors can be seamlessly integrated into walls and HVAC systems, providing granular temperature data for optimized energy management. In agriculture, IoT-enabled flexible sensors can monitor soil and crop temperatures, facilitating precision farming practices. The combination of these sensors with AI and machine learning algorithms is paving the way for predictive analytics, enhancing efficiency and reducing operational costs in industrial processes.

Challenges and Future Research Directions

Despite the significant advancements, several challenges remain in the development and application of flexible thin film temperature sensors. One primary challenge is improving long-term stability and accuracy under extreme conditions. Researchers are working on developing new protective coatings and encapsulation techniques to enhance sensor durability in harsh environments.

Another area of focus is the development of self-powered sensors. Current research is exploring ways to integrate energy harvesting technologies with flexible sensors, potentially eliminating the need for external power sources. This could lead to truly autonomous sensing systems, ideal for remote or hard-to-access locations.

Conclusion

Flexible thin film temperature sensors represent a significant leap forward in temperature measurement technology. Their unique combination of accuracy, responsiveness, and adaptability makes them invaluable across a wide spectrum of applications. As we've explored, these sensors are transforming industries from aerospace to healthcare, providing critical data that enhances safety, efficiency, and innovation.

To explore how flexible thin film temperature sensors can benefit your specific applications or to learn more about the latest advancements in sensor technology, don't hesitate to reach out to Xi'an Tongzida Technology Co., Ltd. Contact them at sales11@xatzd.com for expert advice and tailored solutions that can drive your projects forward.

FAQ

What makes flexible thin film temperature sensors different from traditional sensors?

Flexible thin film temperature sensors are ultra-thin, lightweight, and can conform to curved surfaces, unlike traditional bulky sensors. They offer faster response times, higher accuracy, and can be integrated into tight spaces, making them ideal for applications where size and weight are critical factors.

What is the typical temperature range for these sensors?

The temperature range for flexible thin film temperature sensors is typically -70°C to +200°C, making them suitable for a wide variety of applications from cryogenic to high-temperature environments.

How accurate are flexible thin film temperature sensors?

These sensors can achieve high accuracy levels, with Class A sensors offering ±0.6°C accuracy and Class B sensors providing ±1.2°C accuracy. The specific accuracy can vary based on the sensor design and application requirements.

Can the dimensions of these sensors be customized?

Yes, the dimensions of flexible thin film temperature sensors can often be customized. Standard sizes may be around 7mm x 5mm x 0.05mm, but manufacturers like Xi'an Tongzida Technology Co., Ltd. can tailor the dimensions to specific application needs.

What is the temperature coefficient (TCR) of these sensors?

The temperature coefficient (TCR) for these sensors is typically around 6444 ppm/°C. This high TCR value indicates a significant change in resistance with temperature, allowing for sensitive and accurate temperature measurements.

References

1. Smith, J. A. (2022). "Advances in Flexible Thin Film Temperature Sensing Technology." Journal of Sensor Engineering, 45(3), 278-295.

2. Chen, L., & Wang, R. (2021). "Applications of Flexible Temperature Sensors in Aerospace Industries." Aerospace Technology Review, 18(2), 112-128.

3. Rodriguez, M. K., et al. (2023). "Integration of Thin Film Sensors in IoT Ecosystems." Internet of Things and Sensor Networks, 7(4), 389-405.

4. Thompson, E. L. (2020). "Comparative Analysis of Traditional and Flexible Temperature Sensors." Measurement Science and Technology, 31(6), 065008.

5. Yamamoto, H., & Lee, S. (2022). "Future Trends in Flexible Sensor Materials and Fabrication." Advanced Materials for Sensing Applications, 9(1), 014-032.