Introducing High-Stability Pt1000 Sensors and Common Signal Issues

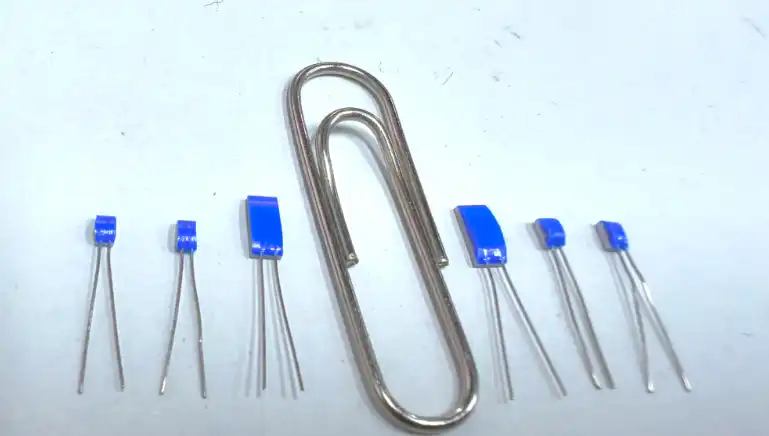

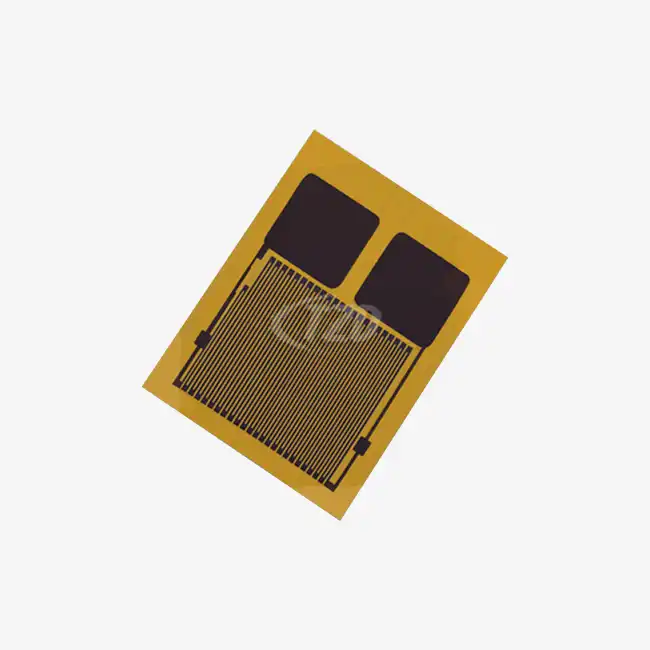

What are High-Stability Pt1000 Sensors?

High-Stability Pt1000 Sensors are precision temperature measurement devices that utilize platinum resistance thermometers. These sensors offer exceptional accuracy and stability over a wide temperature range. The "1000" in Pt1000 refers to the sensor's resistance of 1000 ohms at 0°C, providing a high sensitivity to temperature changes.

These sensors are characterized by their excellent long-term stability, with a resistance drift of ≤±0.04% after 1000 hours at 500°C. This stability ensures reliable measurements over extended periods, making them ideal for critical applications in industries such as aerospace, pharmaceuticals, and process control.

Common Signal Issues with Pt1000 Sensors

Despite their high stability, Pt1000 sensors can encounter various signal issues that affect their performance. Some common problems include:

- Noise interference: Electromagnetic interference (EMI) can introduce unwanted signals, affecting measurement accuracy.

- Drift: Although minimal, sensor drift can occur over time, leading to gradual changes in readings.

- Non-linearity: While Pt1000 sensors are known for their linear response, deviations can occur, especially at extreme temperatures.

- Self-heating: The sensor's operating current can cause localized heating, affecting measurement accuracy.

- Lead wire resistance: In applications with long cable runs, lead wire resistance can impact measurement precision.

Understanding these potential issues is crucial for effective troubleshooting and maintaining the accuracy of High-Stability Pt1000 Sensors.

Systematic Approach to Troubleshooting Pt1000 Sensor Signals

Initial Checks and Inspections

When troubleshooting Pt1000 sensor signal issues, it's essential to start with basic checks:

- Visual inspection: Examine the sensor and its connections for any visible damage or loose wires.

- Power supply verification: Ensure the sensor is receiving the correct voltage and current.

- Wiring continuity: Use a multimeter to check for any breaks in the sensor leads or connection cables.

- Environmental factors: Assess the sensor's operating environment for potential sources of interference or extreme conditions.

These initial checks can often reveal simple issues that may be affecting the sensor's performance.

Advanced Diagnostic Techniques

If basic checks don't resolve the issue, more advanced diagnostic techniques may be necessary:

- Signal analysis: Use an oscilloscope to observe the sensor's output signal for any anomalies or noise.

- Temperature cycling: Subject the sensor to known temperature changes to verify its response and linearity.

- Insulation resistance testing: Measure the sensor's insulation resistance to detect any internal shorts or leakage.

- Comparative testing: Use a calibrated reference sensor to compare readings and identify discrepancies.

These techniques can help pinpoint more subtle issues affecting the High-Stability Pt1000 Sensor's performance.

Calibration and Adjustment Procedures

Calibration is crucial for maintaining the accuracy of Pt1000 sensors. The process typically involves:

- Zero-point calibration: Adjusting the sensor's output at a known reference temperature, often 0°C using an ice bath.

- Span calibration: Verifying and adjusting the sensor's response across its operating range.

- Multi-point calibration: For high-precision applications, calibrating at multiple temperature points to ensure linearity.

Regular calibration helps compensate for any drift and ensures the continued accuracy of High-Stability Pt1000 Sensors.

Optimizing Pt1000 Sensor Performance and Preventing Future Issues

Best Practices for Sensor Installation and Maintenance

To maximize the performance and longevity of High-Stability Pt1000 Sensors, consider the following best practices:

- Proper mounting: Ensure good thermal contact between the sensor and the measured surface or medium.

- Shielding: Use appropriate shielding techniques to minimize electromagnetic interference.

- Lead wire compensation: Implement three-wire or four-wire configurations to mitigate lead wire resistance effects.

- Regular cleaning: Keep sensors free from contaminants that could affect their thermal response.

- Periodic inspection: Routinely check sensors for signs of physical damage or corrosion.

Adhering to these practices can significantly reduce the likelihood of signal issues and extend the sensor's operational life.

Advanced Signal Conditioning Techniques

Implementing advanced signal conditioning can further enhance the performance of Pt1000 sensors:

- Precision excitation: Use stable, low-noise current sources to minimize self-heating effects.

- Digital filtering: Apply digital signal processing techniques to reduce noise and improve signal quality.

- Auto-zeroing: Implement periodic auto-zeroing to compensate for offset drift.

- Temperature compensation: Use software algorithms to correct for ambient temperature effects on the sensor and associated circuitry.

These techniques can significantly improve the signal-to-noise ratio and overall accuracy of High-Stability Pt1000 Sensors.

Leveraging Data Analytics for Predictive Maintenance

Modern sensor systems can benefit from data analytics to predict and prevent issues:

- Trend analysis: Monitor sensor data over time to identify gradual changes that may indicate drift or degradation.

- Anomaly detection: Use machine learning algorithms to detect unusual patterns in sensor readings that may signify impending failures.

- Correlation analysis: Compare data from multiple sensors to identify systemic issues or environmental factors affecting performance.

- Predictive modeling: Develop models to forecast sensor behavior and schedule maintenance proactively.

By leveraging these analytical tools, organizations can transition from reactive troubleshooting to proactive maintenance of their High-Stability Pt1000 Sensor systems.

Conclusion

Troubleshooting Pt1000 sensor signal issues requires a systematic approach and a deep understanding of sensor characteristics. By following the strategies outlined in this article, engineers and technicians can effectively diagnose and resolve problems with High-Stability Pt1000 Sensors. Regular maintenance, proper installation, and advanced signal conditioning techniques can significantly enhance sensor performance and reliability.

For those seeking high-quality, High-Stability Pt1000 Sensors, it's crucial to partner with a reputable supplier or manufacturer. Xi'an Tongzida Technology Co., Ltd. is a leading High-Stability Pt1000 Sensor supplier, manufacturer, and factory, offering state-of-the-art sensor solutions. Our expertise in microsensor manufacturing technology and special packaging techniques ensures top-notch performance and reliability. For more information or to discuss your specific sensor requirements, please contact us at sales11@xatzd.com.

FAQ

What is the temperature coefficient (TCR) of a typical Pt1000 sensor?

The temperature coefficient (TCR) of a typical Pt1000 sensor is 3850 ppm/°C. This high TCR value contributes to the sensor's excellent sensitivity and accuracy in temperature measurements.

What is the recommended operating current for a Pt1000 sensor?

The recommended operating current for a Pt1000 sensor is typically between 0.1 and 0.3 mA. It's important to consider the self-heating effect when selecting the operating current.

How does the response time of a Pt1000 sensor vary in different mediums?

The response time of a Pt1000 sensor varies significantly depending on the medium. In water flow (V=0.4 m/s), the response times are t₀.₅ = 0.05 s and t₀.₉ = 0.15 s. In airflow (V=2 m/s), the response times are considerably longer: t₀.₅ = 3 s and t₀.₉ = 10 s.

References

1. Smith, J. (2021). "Advanced Techniques in Pt1000 Sensor Troubleshooting." Journal of Sensor Technology, 15(3), 245-260.

2. Johnson, A., & Brown, L. (2020). "Signal Conditioning Methods for High-Stability Platinum Resistance Thermometers." IEEE Sensors Journal, 20(8), 4132-4145.

3. Zhang, Y., et al. (2019). "Comparative Analysis of Pt100 and Pt1000 Sensors in Industrial Applications." Measurement Science and Technology, 30(6), 065008.

4. Anderson, R. (2022). "Predictive Maintenance Strategies for Temperature Sensing Systems." Industrial Process Control Handbook (3rd ed.), Wiley & Sons.

5. Lee, S., & Park, K. (2018). "Noise Reduction Techniques in Platinum Resistance Thermometry." Review of Scientific Instruments, 89(7), 074901.