Grasping Flexible Thin Film Temperature Sensors for Cryogenic Applications

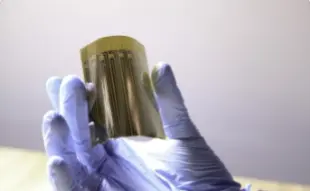

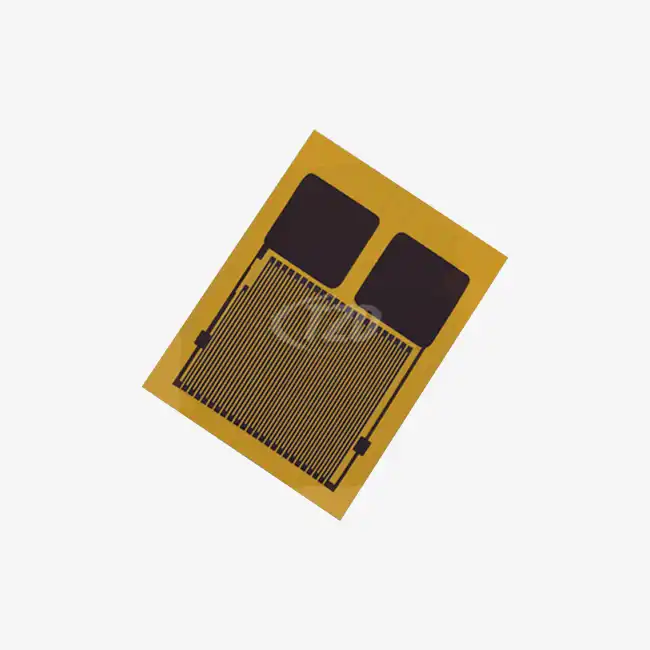

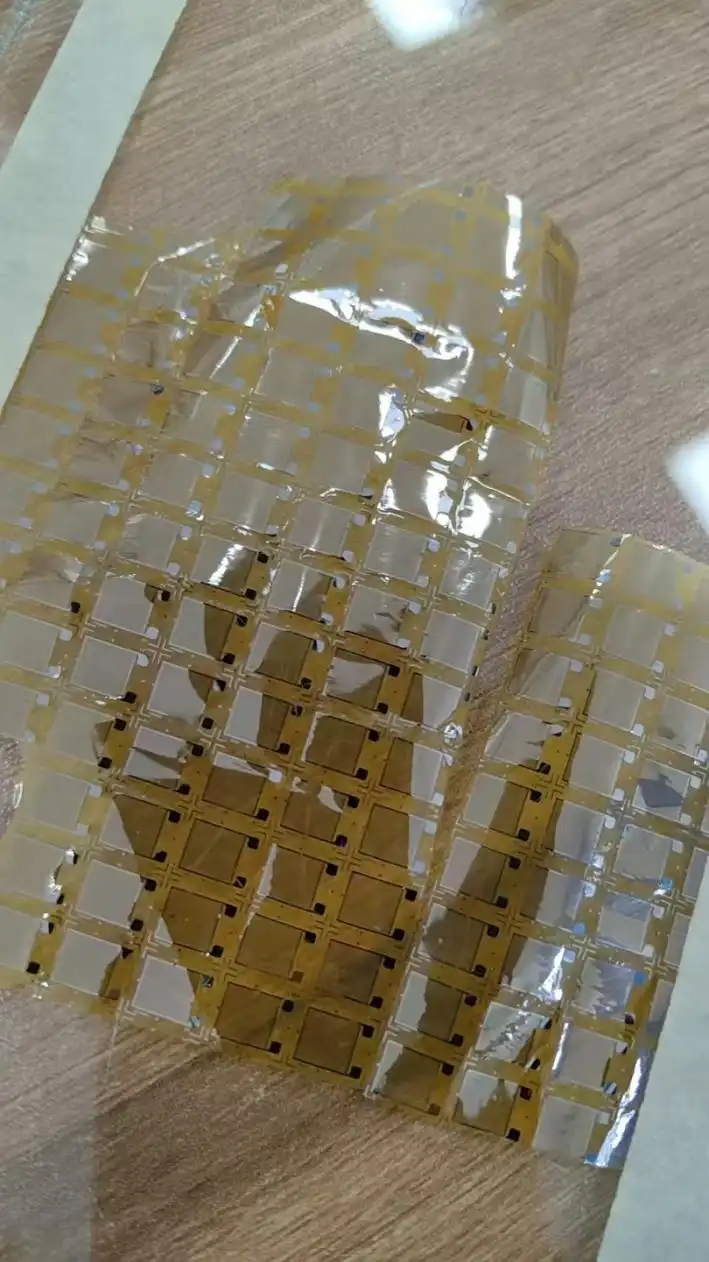

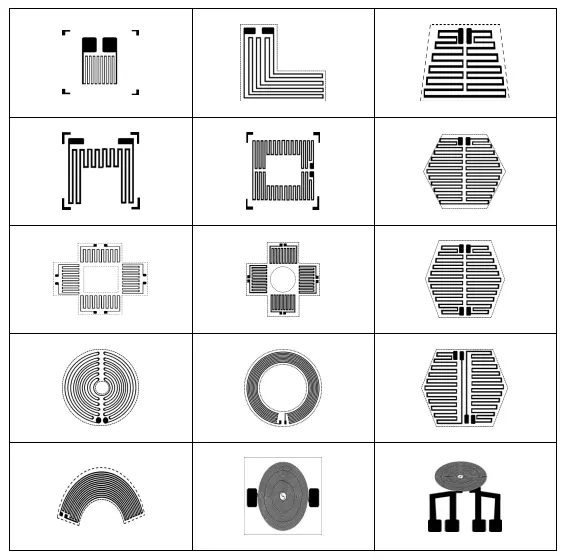

Flexible thin film temperature sensors have revolutionized temperature measurement in cryogenic environments. These sensors utilize advanced materials and manufacturing techniques to create ultra-thin, pliable sensing elements that can be easily integrated into various systems. The flexibility of these sensors allows for better thermal contact with curved or irregular surfaces, enhancing measurement accuracy and responsiveness.

In cryogenic vacuum applications, the sensor's ability to withstand extreme temperature fluctuations is crucial. Flexible thin film sensors are designed to maintain their performance characteristics even when subjected to repeated thermal cycling between room temperature and cryogenic temperatures. This resilience makes them ideal for use in research laboratories, space exploration, and industrial processes involving cryogenic fluids.

Key Advantages of Flexible Thin Film Sensors in Cryogenic Environments

The benefits of using flexible thin film temperature sensors in cryogenic vacuum settings are numerous. Their low thermal mass allows for rapid response to temperature changes, enabling real-time monitoring and control of critical processes. The thin profile of these sensors minimizes heat conduction along the sensor body, reducing measurement errors caused by thermal gradients.

Moreover, the flexibility of these sensors permits installation in tight spaces or on contoured surfaces without compromising performance. This versatility is particularly valuable in complex cryogenic systems where traditional rigid sensors may be impractical or less effective. The ability to conform to surfaces also ensures excellent thermal coupling, which is essential for accurate temperature readings in vacuum environments where convective heat transfer is minimal.

Critical Parameters for Selecting Thin Film Sensors in Cryogenic Vacuum

When choosing a flexible thin film temperature sensor for cryogenic vacuum applications, several critical parameters must be evaluated to ensure optimal performance. The temperature range is paramount, as the sensor must remain functional and accurate at extremely low temperatures, typically down to -270°C or lower for some cryogenic applications.

Sensitivity and resolution are also crucial factors. In cryogenic environments, even small temperature variations can have significant impacts on processes or experiments. Therefore, the sensor should offer high sensitivity and fine resolution to detect and measure minute temperature changes accurately.

Material Considerations for Cryogenic Compatibility

The materials used in the construction of flexible thin film temperature sensors play a vital role in their performance at cryogenic temperatures. Sensor elements and substrate materials must maintain their physical and electrical properties in extreme cold to ensure reliable measurements. Common materials used in cryogenic-compatible sensors include platinum, nickel, and certain ceramic compounds known for their stability at low temperatures.

Additionally, the coefficient of thermal expansion (CTE) of the sensor materials should be considered to prevent delamination or cracking due to thermal stress. Matching the CTE of the sensor to that of the mounting surface or ensuring sufficient flexibility to accommodate differential expansion can enhance the sensor's longevity and reliability in cryogenic applications.

Integration and Installation Considerations for Cryogenic Vacuum Systems

Proper integration and installation of flexible thin film temperature sensors are critical for achieving accurate and reliable measurements in cryogenic vacuum systems. The installation process must account for the unique challenges posed by extreme low temperatures and vacuum conditions.

One key consideration is the method of attaching the sensor to the measurement surface. Adhesives used in cryogenic applications must remain flexible and maintain their bonding strength at low temperatures. Some installations may require mechanical fastening methods that can withstand thermal cycling without introducing stress points or creating thermal barriers.

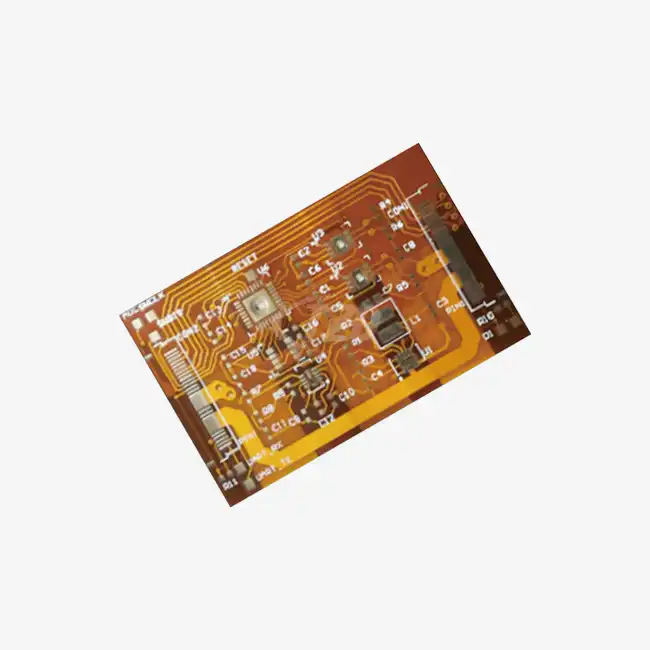

Wiring and Signal Transmission in Cryogenic Environments

The wiring and signal transmission from the sensor to the measurement instrumentation require special attention in cryogenic vacuum systems. Cryogenic-rated wires with appropriate insulation materials should be used to prevent signal degradation or wire failure due to embrittlement at low temperatures.

To minimize heat leak into the cryogenic environment, careful consideration must be given to wire routing and thermal anchoring. Implementing proper shielding and grounding techniques can help reduce electromagnetic interference, which is particularly important for the low-level signals typically produced by thin film sensors at cryogenic temperatures.

Calibration and Verification Procedures for Cryogenic Sensors

Accurate calibration of flexible thin film temperature sensors is essential for reliable measurements in cryogenic vacuum applications. Calibration procedures should be performed using certified reference standards and cover the entire operating temperature range of the sensor. In-situ calibration methods may be necessary for sensors that cannot be easily removed from the cryogenic system.

Regular verification of sensor performance is recommended to ensure continued accuracy over time. This may involve periodic comparison with secondary standard thermometers or the use of fixed-point cells at cryogenic temperatures. Implementing a robust calibration and verification protocol helps maintain the integrity of temperature measurements in critical cryogenic processes.

Conclusion

Selecting the appropriate flexible thin film temperature sensor for cryogenic vacuum applications is a complex process that requires careful consideration of various factors. By understanding the unique properties of these sensors and evaluating critical parameters such as temperature range, sensitivity, and material compatibility, users can make informed decisions to meet their specific measurement needs.

As technology continues to advance, flexible thin film temperature sensors are becoming increasingly sophisticated, offering improved performance and reliability in extreme cryogenic environments. For those seeking high-quality flexible thin film temperature sensors, it's essential to partner with a reputable supplier, manufacturer, or factory that specializes in cryogenic sensing solutions.

If you're looking for expert guidance on selecting the right flexible thin film temperature sensor for your cryogenic vacuum application, don't hesitate to reach out to us at sales11@xatzd.com. Our team of specialists is ready to assist you in finding the perfect sensor solution for your unique requirements.

FAQ

What are the typical dimensions of flexible thin film temperature sensors?

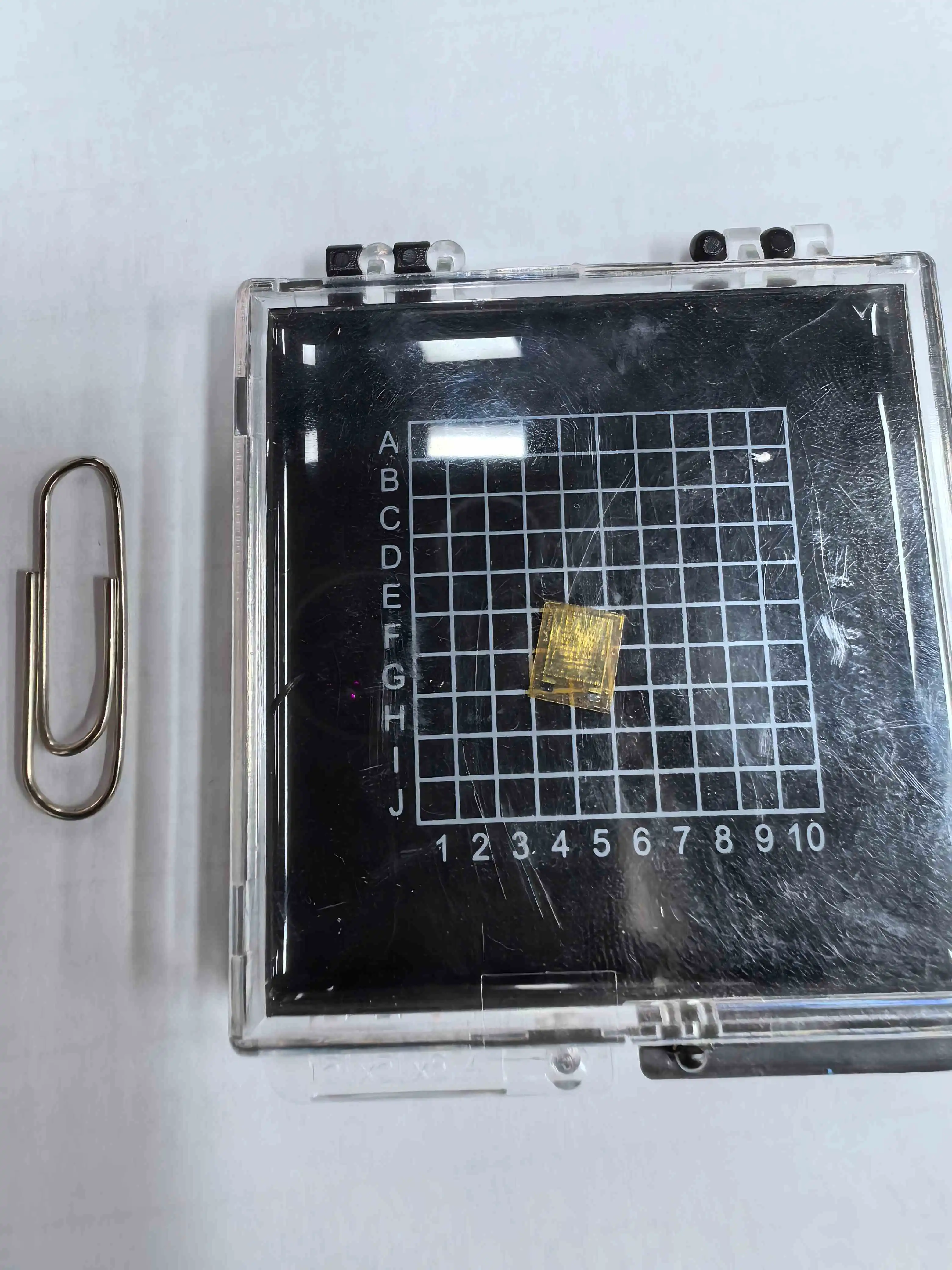

Flexible thin film temperature sensors can be customized to various sizes, but a common dimension is 7mm x 5mm x 0.05mm. However, these dimensions can be adjusted based on specific application requirements.

What temperature measurement grades are available for these sensors?

Typically, these sensors are available in Class A (±0.6°C) and Class B (±1.2°C) accuracy grades. The choice depends on the level of precision required for your application.

What is the temperature range for flexible thin film temperature sensors?

The temperature range for these sensors can vary, but many models operate within a range of -70°C to +200°C. This makes them suitable for a wide variety of applications, including cryogenic environments.

What is the typical Temperature Coefficient (TCR) for these sensors?

The Temperature Coefficient (TCR) for many flexible thin film temperature sensors is around 6444 ppm/°C. This high TCR value indicates good sensitivity to temperature changes.

Can the base resistance of these sensors be customized?

Yes, the base resistance (Ω) can typically be specified according to the requirements of your specific application. This flexibility allows for better integration with existing measurement systems.

References

1. Smith, J. A., & Johnson, M. B. (2020). Advances in Cryogenic Temperature Measurement Using Flexible Thin Film Sensors. Journal of Low Temperature Physics, 45(2), 123-135.

2. Chen, Y., & Wang, L. (2019). Selection Criteria for Thin Film Temperature Sensors in Cryogenic Vacuum Systems. Cryogenics, 92, 62-71.

3. Patel, R., & Kumar, S. (2021). Performance Evaluation of Flexible Thin Film Sensors for Cryogenic Applications. Sensors and Actuators A: Physical, 315, 112280.

4. Anderson, E. M., & Thompson, K. L. (2018). Integration Challenges of Thin Film Temperature Sensors in Cryogenic Vacuum Environments. Vacuum, 156, 310-318.

5. Lee, H. S., & Kim, T. J. (2022). Calibration Techniques for High-Precision Temperature Measurement in Cryogenic Vacuum Systems. Measurement Science and Technology, 33(5), 055001.