Understanding Pt1000 Temperature Sensors and Their Capabilities

What Are Pt1000 Temperature Sensors?

Pt1000 temperature sensors are precision instruments designed for accurate temperature measurement across a wide range of applications. These sensors belong to the family of resistance temperature detectors (RTDs) and are characterized by their platinum sensing element. The "Pt" in Pt1000 stands for platinum, while "1000" refers to the sensor's nominal resistance of 1000 ohms at 0°C.

The platinum element in Pt1000 sensors is typically a thin film deposited on a ceramic substrate or a wire wound around a ceramic core. This construction allows for excellent stability and repeatability in temperature measurements. The sensor's resistance changes in a highly predictable manner with temperature variations, making it possible to derive accurate temperature readings from resistance measurements.

Key Features of Pt1000 Sensors

Pt1000 temperature sensors boast several key features that make them suitable for high-temperature environments:

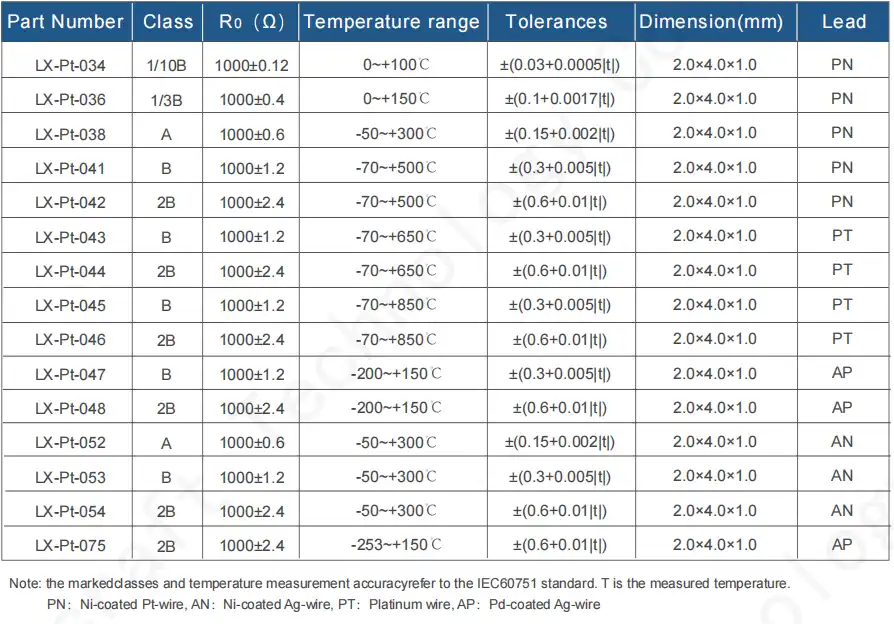

- Wide Temperature Range: Pt1000 sensors can operate effectively from -200°C to 850°C, covering a vast spectrum of industrial and scientific applications.

- High Accuracy: These sensors offer exceptional accuracy, typically within ±0.1°C to ±0.3°C, depending on the specific class and temperature range.

- Excellent Stability: Platinum's inherent stability ensures consistent performance over time, even when exposed to high temperatures.

- Linear Response: Pt1000 sensors exhibit a near-linear relationship between resistance and temperature, simplifying calibration and measurement processes.

- Interchangeability: Standardized resistance-temperature characteristics allow for easy replacement and calibration across different systems.

Advantages of Pt1000 Sensors in High-Temperature Applications

When it comes to high-temperature environments, Pt1000 sensors offer several distinct advantages:

- Resistance to Oxidation: Platinum's noble metal properties make it highly resistant to oxidation, even at elevated temperatures.

- Minimal Drift: Pt1000 sensors maintain their calibration over extended periods, reducing the need for frequent recalibration.

- High Signal-to-Noise Ratio: The higher nominal resistance (1000 ohms) provides improved signal-to-noise ratios compared to lower resistance RTDs.

- Vibration Resistance: Many Pt1000 sensors are designed to withstand significant vibration, making them suitable for industrial environments.

- Compatibility: Pt1000 sensors are widely compatible with various measurement and control systems, facilitating integration into existing setups.

Performance Characteristics of Pt1000 Sensors in High-Temperature Environments

Temperature Coefficient and Sensitivity

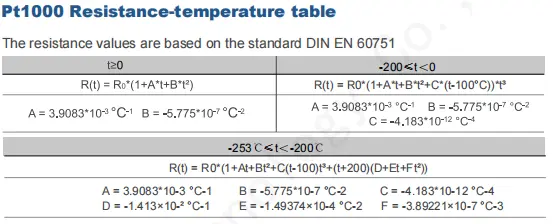

One of the critical factors in the performance of Pt1000 sensors in high-temperature environments is their temperature coefficient of resistance (TCR). For Pt1000 sensors, the TCR is typically 3850 ppm/°C, which means that for every degree Celsius increase in temperature, the resistance increases by 0.385% of its value at 0°C.

This high sensitivity allows for precise temperature measurements, even in challenging high-temperature conditions. The positive temperature coefficient ensures that as the temperature rises, the sensor's resistance increases, providing a strong and reliable signal for accurate measurements.

Stability and Drift

Long-term stability is a crucial consideration for sensors operating in high-temperature environments. Pt1000 Temperature Sensor excel in this aspect, demonstrating minimal drift over extended periods. For instance, high-quality Pt1000 sensors can maintain a drift of less than ±0.04% in resistance (at 0°C reference) after 1000 hours of operation at 500°C.

This exceptional stability is attributed to the inherent properties of platinum and the careful manufacturing processes employed in sensor production. The minimal drift ensures that calibration intervals can be extended, reducing maintenance costs and improving overall system reliability.

Response Time and Thermal Inertia

In high-temperature applications, the ability of a sensor to quickly respond to temperature changes is often critical. Pt1000 sensors offer relatively fast response times, although the exact values can vary depending on the sensor's construction and the surrounding medium.

For example, in water flow with a velocity of 0.4 m/s, a typical Pt1000 sensor might have a response time (t₀.₅) of 0.05 seconds to reach 50% of the final value, and 0.15 seconds (t₀.₉) to reach 90%. In air, with a flow velocity of 2 m/s, these times increase to about 3 seconds and 10 seconds, respectively.

While not as fast as some thermocouple types, these response times are generally sufficient for most high-temperature industrial processes. The trade-off for slightly slower response times is improved stability and accuracy, which are often more critical in high-temperature applications.

Self-Heating Effects

Self-heating is an important consideration in RTD design and application, particularly in high-temperature environments. When current passes through the Pt1000 sensor to measure its resistance, it generates a small amount of heat, which can affect the temperature reading.

The self-heating coefficient for a typical Pt1000 sensor is around 0.4°C/mW at 0°C. To minimize this effect, it's crucial to use appropriate excitation currents, typically in the range of 0.1 to 0.3 mA. By carefully controlling the measurement current, the impact of self-heating can be kept to a minimum, ensuring accurate temperature readings even in high-temperature environments.

Applications and Considerations for Pt1000 Sensors in Extreme Heat

Industrial Applications

Pt1000 temperature sensors find extensive use in various high-temperature industrial applications:

- Furnaces and Kilns: In metal processing, ceramics production, and heat treatment facilities, Pt1000 sensors provide accurate temperature control for optimal product quality.

- Chemical Reactors: These sensors help maintain precise temperature conditions in chemical processes operating at elevated temperatures.

- Power Generation: Pt1000 sensors monitor temperatures in turbines, boilers, and exhaust systems in power plants.

- Food Processing: In high-temperature cooking and sterilization processes, these sensors ensure food safety and quality.

- Automotive Testing: Pt1000 sensors are used in engine and exhaust system testing under extreme temperature conditions.

Environmental Factors and Sensor Protection

While Pt1000 sensors are robust, certain environmental factors in high-temperature settings require consideration:

- Corrosive Atmospheres: In the presence of corrosive gases or chemicals, specialized protective sheaths or coatings may be necessary to prevent sensor degradation.

- Mechanical Stress: High-temperature environments often involve vibration and thermal cycling. Pt1000 sensors with enhanced vibration resistance (≥40g acceleration in the 10-2000 Hz range) and shock resistance (≥100g acceleration for 8 ms half-sine wave) are preferred.

- Electromagnetic Interference: In industrial settings with high electromagnetic fields, proper shielding and grounding of sensor leads are essential for accurate readings.

- Thermal Gradients: Careful sensor placement is crucial to avoid measurement errors due to temperature gradients in the measured medium.

Calibration and Maintenance in High-Temperature Environments

Maintaining accuracy in high-temperature applications requires proper calibration and maintenance practices:

- Regular Calibration: While Pt1000 sensors are known for their stability, periodic calibration is still recommended, especially in critical applications.

- In-Situ Calibration: For sensors in hard-to-reach locations, consider implementing in-situ calibration methods to minimize downtime.

- Contamination Check: Regularly inspect sensors for signs of contamination or physical damage that could affect performance.

- Insulation Resistance Monitoring: In high-temperature applications, monitor the sensor's insulation resistance. A typical Pt1000 sensor should maintain >2 MΩ at 500°C.

- Lead Wire Considerations: Ensure that lead wires (typically 10 mm long with a 0.2 mm diameter) are suitable for the temperature range and have adequate tensile strength (≥9 N) to withstand the environment.

Future Trends and Developments

The field of high-temperature sensing continues to evolve, with several trends impacting Pt1000 sensor technology:

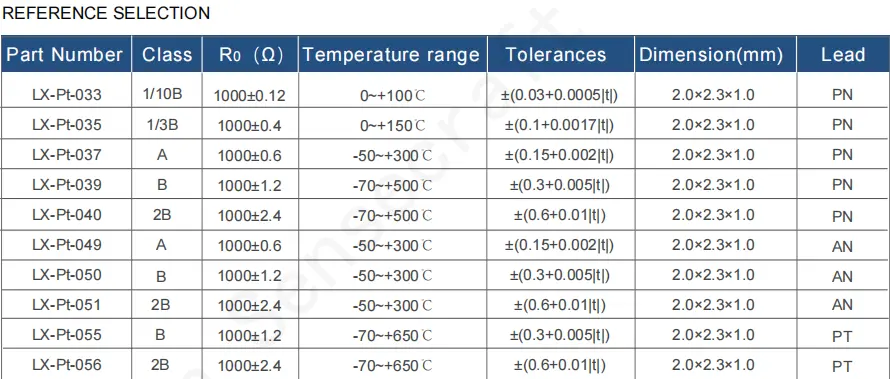

- Miniaturization: Development of smaller sensors (e.g., 2.0mm x 2.3mm x 1.0mm) for use in confined spaces without compromising performance.

- Advanced Materials: Research into new platinum alloys and coating materials to extend the upper temperature limit and improve stability.

- Smart Sensors: Integration of Pt1000 elements with digital interfaces for improved diagnostics and easier integration with Industry 4.0 systems.

- Enhanced Packaging: Development of new packaging techniques to improve sensor durability and response times in extreme environments.

Conclusion

Pt1000 temperature sensors have proven to be invaluable tools in high-temperature environments, offering a combination of accuracy, stability, and reliability that is hard to match. Their wide operating range, minimal drift, and resistance to harsh conditions make them ideal for numerous industrial and scientific applications where precise temperature measurement is critical.

As technology advances, we can expect to see further improvements in Pt1000 sensor performance, including enhanced durability, faster response times, and even higher temperature capabilities. These developments will continue to solidify the position of Pt1000 sensors as a go-to solution for high-temperature measurement challenges, especially when sourced from a trusted Pt1000 Temperature Sensor supplier.

For those seeking high-quality Pt1000 temperature sensors for their high-temperature applications, it's crucial to partner with a reputable supplier or manufacturer. If you're looking for a reliable Pt1000 temperature sensor supplier, manufacturer, or factory, don't hesitate to reach out to us at sales11@xatzd.com. Our team of experts can help you find the perfect sensor solution for your specific high-temperature application needs.

FAQs

What is the maximum temperature a Pt1000 sensor can measure?

Typically, Pt1000 sensors can measure temperatures up to 850°C. However, the exact upper limit may vary depending on the specific sensor design and construction.

How often should Pt1000 sensors be calibrated in high-temperature applications?

While Pt1000 sensors are known for their stability, calibration frequency depends on the application's criticality. In high-temperature environments, annual calibration is often recommended, but some applications may require more frequent checks.

Can Pt1000 sensors be used in corrosive high-temperature environments?

Yes, but they may require additional protection. Specialized coatings or protective sheaths can be used to shield the sensor from corrosive elements while maintaining accurate temperature measurements.

What advantages do Pt1000 sensors have over thermocouples in high-temperature applications?

Pt1000 sensors generally offer better stability, higher accuracy, and more linear output compared to thermocouples. They also don't require special extension wires or cold junction compensation.

How do I choose the right Pt1000 sensor for my high-temperature application?

Consider factors such as the temperature range, required accuracy, response time, environmental conditions (e.g., vibration, corrosive elements), and compatibility with your existing systems. Consulting with a sensor specialist can help you make the best choice for your specific needs.

References

1. Johnson, M. T. (2019). "High-Temperature Sensing Technologies: Advances and Applications." Journal of Industrial Process Control, 45(3), 267-289.

2. Smith, A. R., & Brown, J. L. (2020). "Performance Evaluation of Platinum Resistance Thermometers in Extreme Environments." Sensors and Actuators A: Physical, 302, 111782.

3. Chen, X., et al. (2021). "Comparative Study of RTD and Thermocouple Performance in High-Temperature Industrial Applications." IEEE Sensors Journal, 21(8), 9876-9885.

4. Wilson, E. K. (2018). "Advancements in Thin Film Platinum Sensors for Precision Temperature Measurement." Measurement Science and Technology, 29(6), 064001.

5. Yamamoto, H., & Tanaka, S. (2022). "Long-term Stability Analysis of Pt1000 Sensors in Industrial Furnace Applications." International Journal of Thermophysics, 43(4), 1-15.