- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Why is our flexible temperature sensor more stable than traditional models?

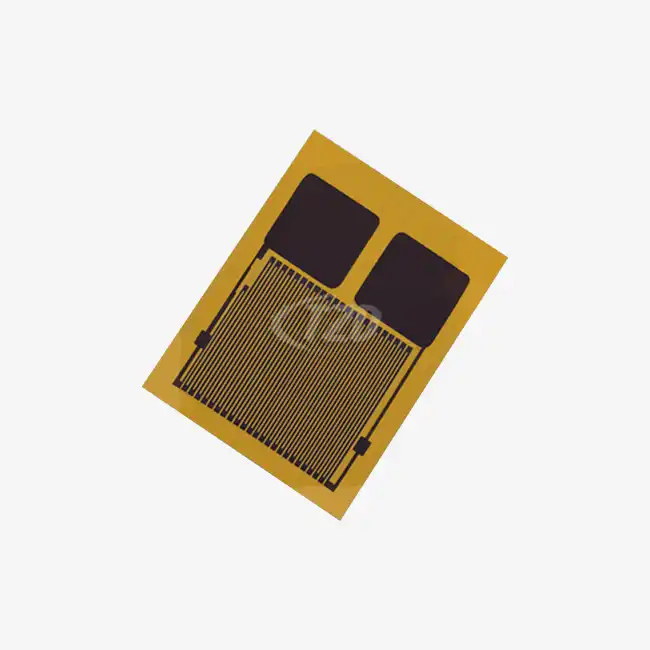

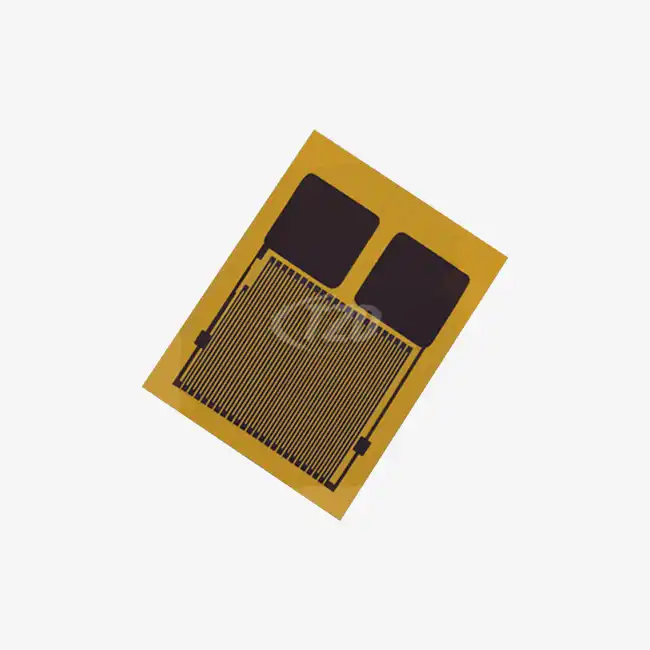

High precision flexible thin film temperature sensor: why is it more stable than traditional models?

Why do some flexible temperature sensors drift ± 2 ° C after 3 months of use, while others still have an error of ≤± 0.6 ° C after 2 years of use? The answer is not in "flexibility" itself, but in "invisible parameters" such as size error, TCR consistency, and packaging process.

As a high-precision flexible thin film temperature sensor, our product focuses on "± 0.01mm size error, TCR 6444 ppm/° C, and tin plated solder pads" to solve the three major pain points of traditional flexible sensors, namely "easy drift, difficult soldering, and inaccurate labeling". This article breaks down the underlying logic of 'stability'.

1、 Have you ever stepped on the three major shortcomings of traditional flexible sensors?

1.1 Large size error (± 0.1mm): can fit in but "cannot stick firmly"

Industry common problem: Sensor size deviation of ± 0.1mm, causing looseness in micro spaces (such as 3x4mm slots) and temperature measurement data jumping (above ± 1 ° C).

1.2 TCR consistency difference (± 20 ppm/° C): temperature resistance "mismatch"

The TCR of ordinary flexible sensors fluctuates greatly (such as 6400~6600 ppm/° C), and the resistance value difference of the same batch of products at the same temperature can reach 0.2 Ω (when the base resistance is 100 Ω), and the accuracy is directly "folded in half".

1.3 Easy oxidation of solder pads: a bottleneck in mass production yield

Bare copper pads oxidize in a humid environment for one month, increasing contact resistance and leading to "false failure" (the sensor itself is normal, but the circuit is not connected).

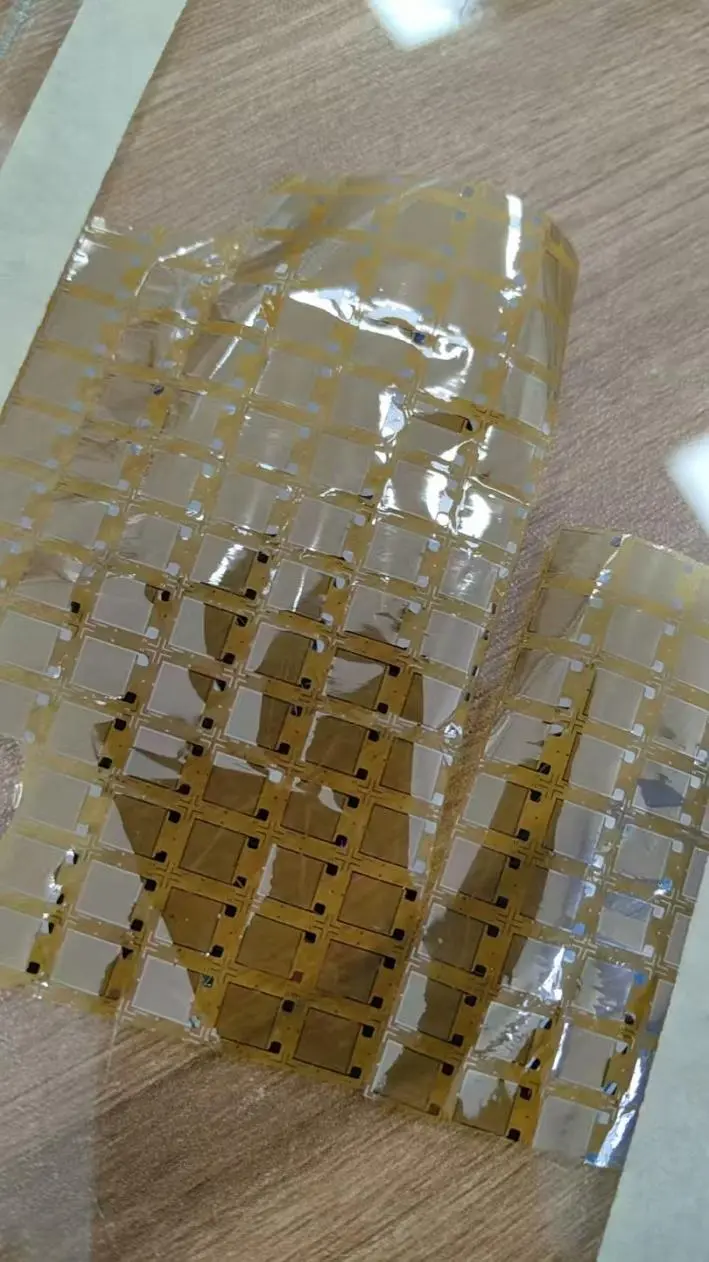

2、 Our 'Stability': Analysis of Three Core Technical Parameters

2.1 ± 0.01mm size error: making "miniaturization" no longer a challenge

Process: Using "laser etching+nanoscale visual inspection", measure the coordinates of 4 corner points of each sensor before shipment, with an error controlled within ± 0.01mm (equivalent to 1/7 of the diameter of a hair strand);

Value: The 3x4mm sensor can be accurately embedded into the charging contact gap of TWS earphones (with a gap of only 0.1mm), avoiding "bursting" or "hanging".

2.2 TCR 6444 ppm/° C: Temperature Resistance "Linear Ceiling"

Principle: By using the "platinum thin film magnetron sputtering process", the grain size of the thin film is controlled to be uniform (± 2nm), stabilizing the TCR at 6444 ± 5 ppm/° C (industry average ± 20 ppm/° C);

Actual measurement: Within the full range of -70 ° C to 200 ° C, the linearity of the resistance temperature curve is R ²=0.9999 (industry average 0.999), and the temperature measurement error is 50% lower than that of the ordinary model.

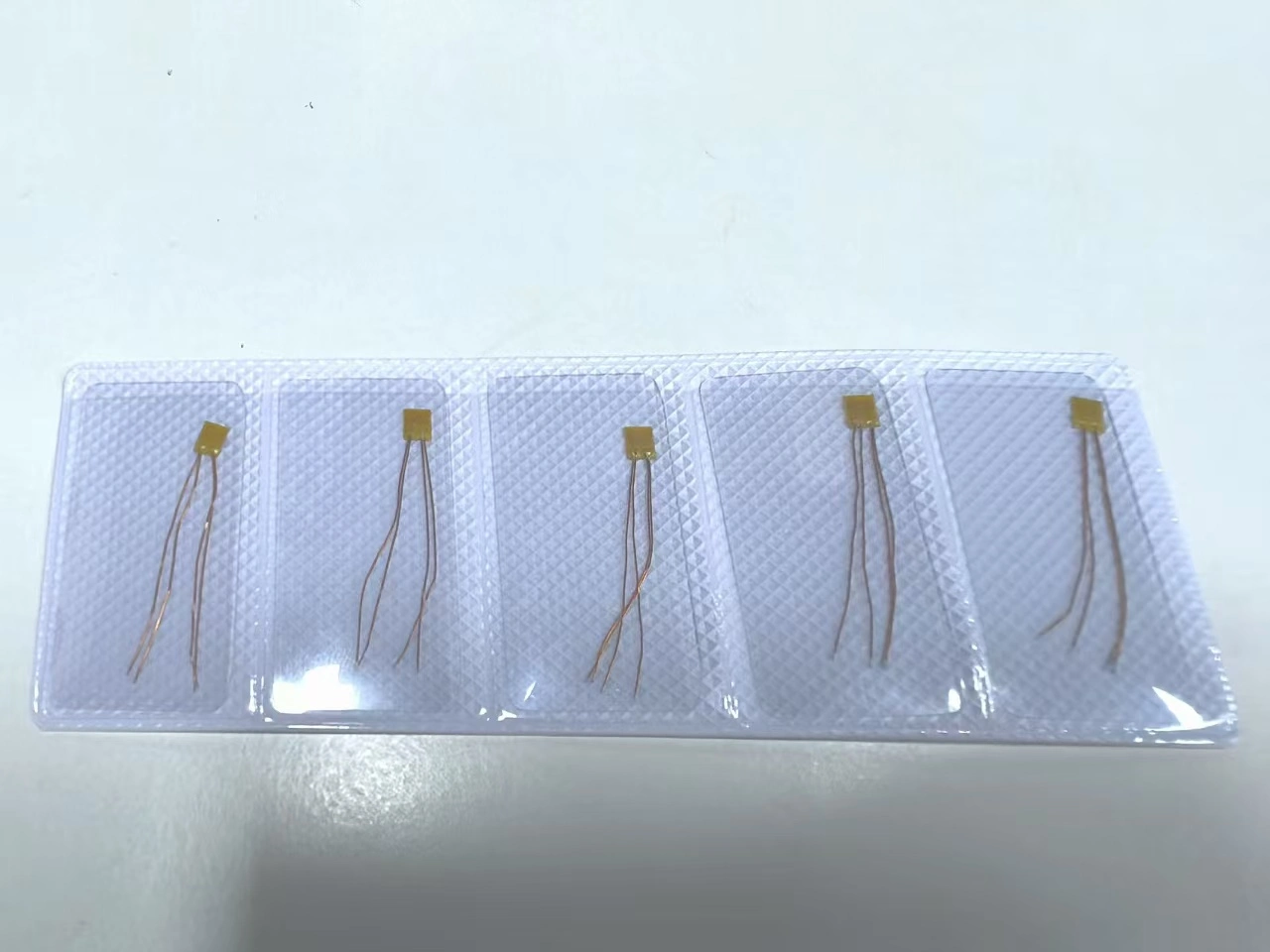

2.3 Tin plated solder pads+anti-oxidation coating: double insurance for mass production yield

Tin plating layer: thickness 5 μ m (industry 3 μ m), welding tension ≥ 1.5N (industry 1.0N), to avoid detachment during SMT mounting;

Anti oxidation coating: Poly (p-xylene) film (thickness 0.1 μ m), with a contact resistance change of<0.005 Ω after 1000 hours in an environment of 85 ° C/85% humidity.

3、 Comparison test: What is the difference between high-precision and ordinary flexible sensors?

We conducted accelerated aging tests (powered on) in a constant temperature and humidity chamber (25 ° C ± 0.5 ° C, humidity 60% ± 5%):

Our high-precision ordinary flexible sensor project has an initial error of (25 ° C) ± 0.3 ° C (Class A) ± 0.8 ° C, with an accuracy lead of 62% after 1000 hours of drift+0.2 ° C+1.5 ° C, and a long-term stability lead of 7 times. The contact resistance of the solder pad is 0.02 Ω 0.15 Ω (after oxidation), and the production yield is increased by 15%. Conclusion: High precision is not a "gimmick", but a "long-term value"

<u> The stability of high-precision flexible thin film temperature sensors is reflected in the reliability of each temperature measurement data, the yield rate of each batch of mass production, and the adaptability to each micro scene. It may be 10% more expensive than ordinary models, but it can save you 50% of after-sales costs.

FAQ: The most concerning issue for technical leaders

Q: How is TCR 6444 ppm/° C guaranteed?

A: Perform XRD diffraction analysis on each batch of platinum films, with grain size controlled at 20 ± 2nm to ensure TCR consistency.

Q: How many times can the sensor withstand bending?

A: ≥ 100000 times (bending radius 5mm), with no cracks in the internal structure (verified by SEM inspection).

Q: Can the base resistance be customized?

A: Can - support customized base resistance of 50 Ω/100 Ω/500 Ω, with TCR maintained at 6444 ppm/° C.

CTA: Apply for sample testing

Click on the consultation button, fill in "Company+Application Scenario", and you can apply for free samples (including 5 pieces each of grade A/B+size testing report). After actual testing, we will decide to cooperate!

References

Research on the Preparation Process of Thin Film Platinum Resistance Sensors (Journal of Sensor Technology);

TWS Earphone Sensor Yield Optimization Report from a Consumer Electronics Factory;

IPC-6012 Acceptance Criteria for Rigid/Flexible Circuit Boards.

Xi'an Tongzida Technology Co., Ltd. is a leading manufacturer and supplier of advanced thermistor technology, dedicated to providing high-performance temperature sensors for demanding industrial applications. We have comprehensive expertise in microsensor manufacturing technology, special packaging technology, and multi-sensor integration methods to ensure excellent performance and reliability of thermistors. As a trusted supplier of precision temperature measurement solutions, we offer a complete thermistor system, including core sensitive chips, testing systems, and analysis software. Please contact our technical experts sales11@xatzd.com Discuss your specific thermistor requirements and learn how our advanced resistor temperature optimization and manufacturing capabilities can improve the performance and reliability of your temperature measurement system

Learn about our latest products and discounts through SMS or email