- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What are the differences between Pt100, Pt1000, and NTC sensors?

Pt100, Pt1000, and NTC sensors are all temperature measurement devices, but they differ in their composition, sensitivity, and applications. Pt100 thin film sensors and Pt1000 are both platinum resistance thermometers (PRTs) with different resistance values at 0°C (100Ω and 1000Ω, respectively). They offer high accuracy and stability over a wide temperature range. NTC (Negative Temperature Coefficient) sensors, on the other hand, are thermistors made from semiconductor materials. They provide higher sensitivity at lower temperatures but have a non-linear response. The choice between these sensors depends on the specific application requirements, such as temperature range, accuracy, and cost considerations.

Comprehending Pt100 Thin Film Sensors: A Technological Marvel

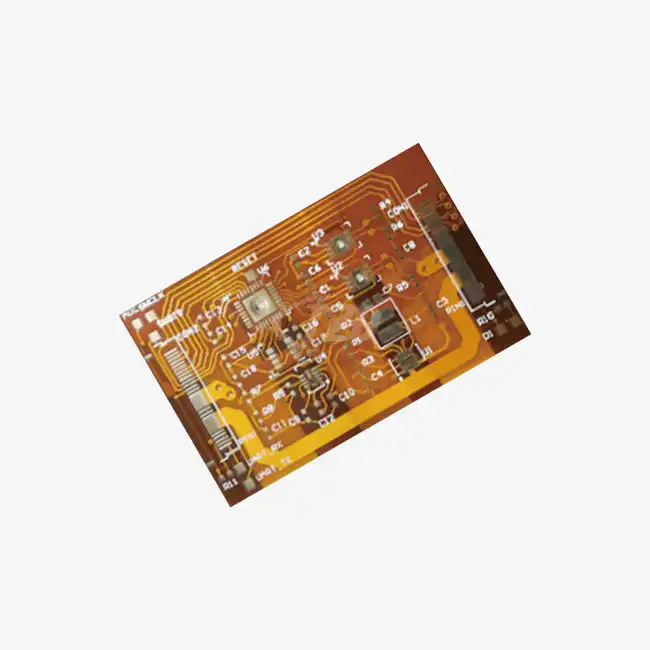

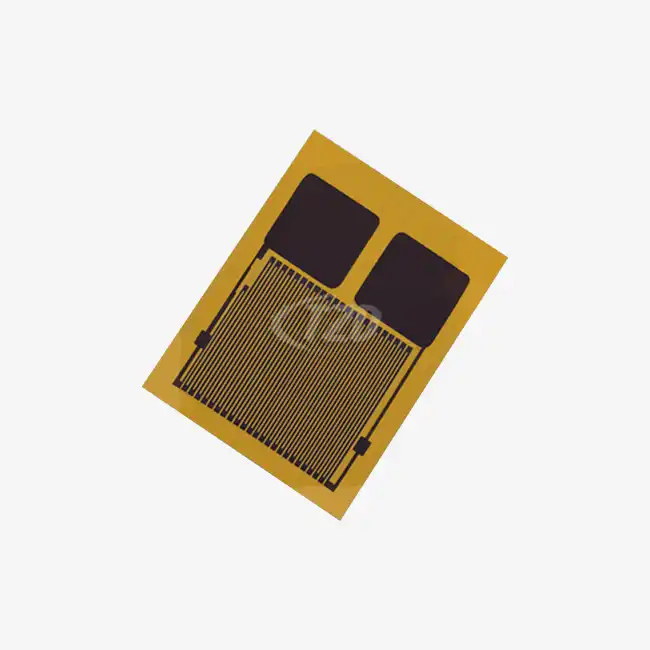

Pt100 thin film sensors represent a significant advancement in temperature measurement technology. These sensors are crafted using precision thin-film deposition techniques, resulting in a compact and highly responsive device. The platinum resistance element is typically deposited on a ceramic substrate, creating a sensor that combines accuracy with rapid response times.

One of the key advantages of Pt100 thin film sensors is their exceptional stability. For instance, our thin film platinum resistor series boasts a long-term stability drift of ≤ 0.04%, ensuring reliable measurements over extended periods. This stability is crucial in applications where consistent accuracy is paramount, such as in industrial processes or medical equipment.

The temperature coefficient of resistance (TCR) for Pt100 thin film sensors is standardized at 3850 ppm/°C, in compliance with the IEC60751 standard. This standardization ensures consistency across different manufacturers and applications, making Pt100 sensors a versatile choice for various industries.

Dimensional Advantages of Pt100 Thin Film Sensors

The compact nature of thin film sensors is one of their most appealing features. With dimensions as small as 3.2mm x 1.6mm x 0.7mm, these sensors can be integrated into space-constrained applications without compromising performance. This miniaturization is particularly beneficial in modern electronic devices and compact industrial equipment.

Despite their small size, Pt100 thin film sensors offer robust performance. They can withstand significant vibration (up to 40g) and impact (up to 100g), making them suitable for use in challenging environments such as automotive and aerospace applications.

Comparative Analysis: Pt100 vs. Pt1000 vs. NTC Sensors

While Pt100 thin film sensors offer numerous advantages, it's essential to understand how they compare to other common temperature sensing technologies like Pt1000 and NTC sensors.

Temperature Range and Accuracy

Pt100 and Pt1000 sensors share similar characteristics in terms of temperature range and accuracy. Both can operate effectively from -200°C to +850°C, with Pt100 thin film sensors typically covering a range of -50°C to +200°C. The accuracy of these platinum-based sensors is exceptional, with some high-precision models offering accuracy as high as ± 0.01Ω.

NTC sensors, while highly sensitive at lower temperatures, generally have a more limited temperature range, typically from -50°C to +150°C. Their non-linear response can make them less accurate than platinum sensors over a wide temperature range.

Response Time and Sensitivity

One of the standout features of Pt100 thin film sensors is their rapid response time. With response times as low as 0.05 seconds, these sensors can detect temperature changes almost instantaneously. This quick response is crucial in applications requiring real-time temperature monitoring and control.

Pt1000 sensors, due to their higher resistance, may offer slightly better resolution in some applications. However, the difference in performance between Pt100 and Pt1000 sensors is often negligible in most practical applications.

NTC sensors generally offer higher sensitivity at lower temperatures, making them ideal for applications where small temperature changes need to be detected in environments close to room temperature.

Applications and Industry-Specific Uses of Pt100 Thin Film Sensors

The versatility and reliability of Pt100 thin film sensors make them indispensable in various industries. Their wide temperature range, high accuracy, and stability contribute to their popularity across different applications.

Industrial and Manufacturing

In industrial settings, Pt100 thin film sensors play a crucial role in process control and monitoring. Their ability to withstand harsh environments, coupled with their high accuracy, makes them ideal for use in chemical processing plants, food and beverage production, and pharmaceutical manufacturing.

The compact size of these sensors allows for easy integration into various industrial equipment, from large reactors to small-scale precision instruments. Their fast response time ensures that temperature changes are detected quickly, allowing for rapid adjustments in critical processes.

Medical and Healthcare

The medical industry relies heavily on precise temperature measurements, and Pt100 thin film sensors excel in this domain. These sensors are used in a wide range of medical devices, from diagnostic equipment to therapeutic applications.

For instance, in medical imaging equipment like MRI machines, Pt100 sensors help maintain the precise temperature control required for optimal performance. In patient monitoring systems, these sensors provide accurate body temperature readings, crucial for patient care and diagnosis.

Automotive and Aerospace

The automotive and aerospace industries demand sensors that can perform reliably under extreme conditions. Pt100 thin film sensors, with their ability to withstand high vibration and impact, are well-suited for these applications.

In automotive applications, these sensors are used in engine management systems, exhaust gas recirculation systems, and battery temperature monitoring in electric vehicles. In aerospace, they play a vital role in aircraft engine monitoring, environmental control systems, and in-flight data recording.

The wide temperature range of Pt100 sensors (-50°C to +200°C for typical thin film models, and up to +850°C for specialized versions) makes them particularly valuable in these industries, where temperature extremes are common.

Research and Development

In scientific research and development, precision and reliability are paramount. Pt100 thin film sensors are widely used in laboratory equipment, environmental chambers, and experimental setups where accurate temperature control and measurement are critical.

The high stability of these sensors (with long-term stability drift ≤ 0.04%) ensures that experimental conditions remain consistent over extended periods, a crucial factor in many research applications.

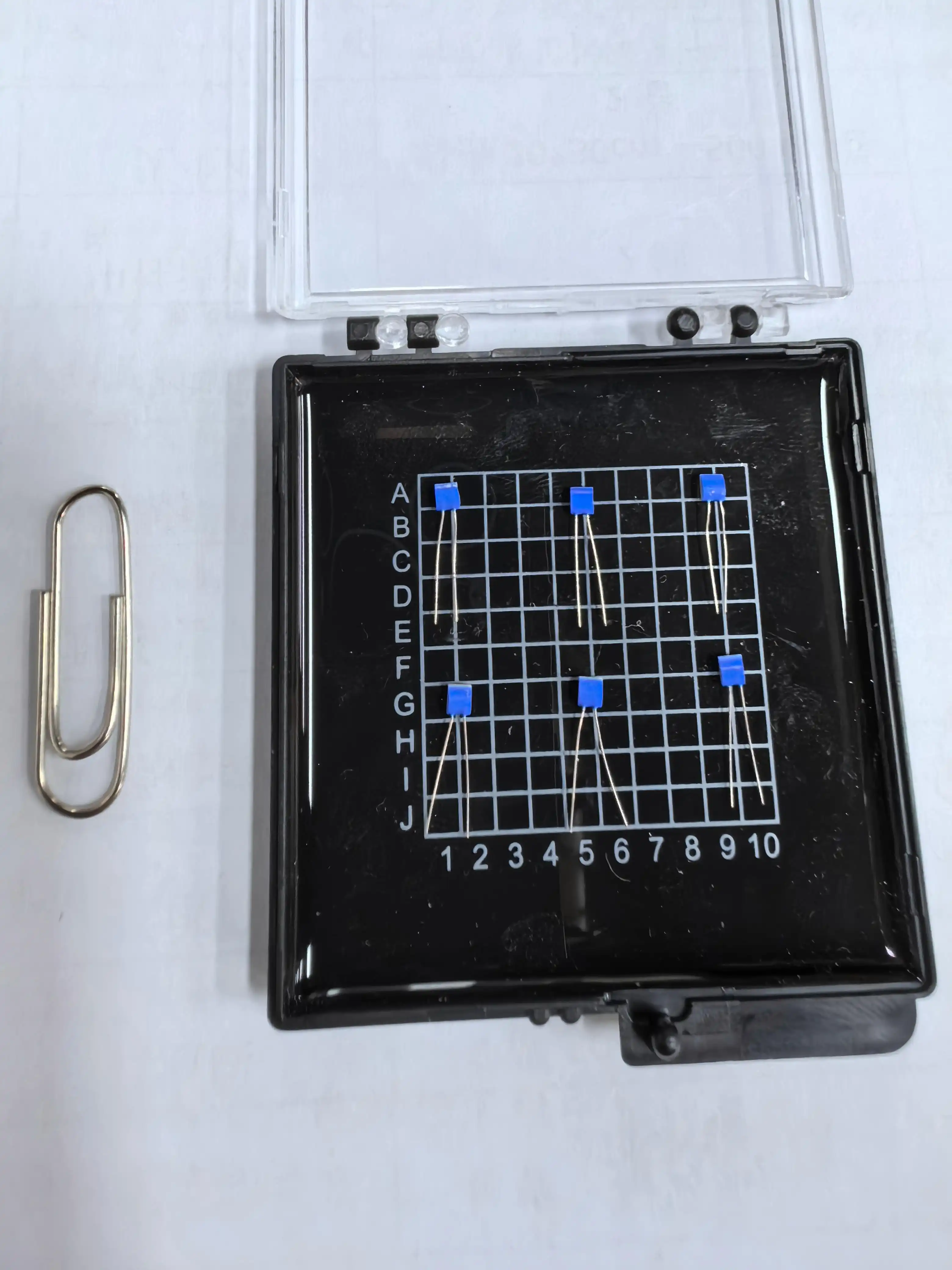

Furthermore, the customization options available for Pt100 thin film sensors, including various sizes (1.2mm to 4.0mm) and lead materials (platinum nickel, silver nickel, pure platinum), allow researchers to tailor these sensors to their specific experimental requirements.

Conclusion

Pt100 thin film sensors represent a pinnacle in temperature sensing technology, offering a unique combination of accuracy, stability, and versatility. Their compact size, rapid response time, and ability to withstand harsh conditions make them an ideal choice for a wide range of applications across various industries.

While Pt1000 and NTC sensors have their specific advantages, the Pt100 thin film sensor's balance of performance characteristics often makes it the preferred choice in many high-demand scenarios. As technology continues to advance, we can expect further innovations in thin film sensor technology, potentially expanding their capabilities and applications even further.

For those seeking high-quality Pt100 thin film sensors or looking to explore custom solutions for specific applications, our team at Xi'an Tongzida Technology Co., Ltd. is ready to assist. With our advanced manufacturing capabilities and commitment to quality, we provide sensors that meet the most demanding requirements across industries. For more information or to discuss your specific needs, please contact us at sales11@xatzd.com.

References

1. Smith, J. A. (2020). "Temperature Sensor Technologies: A Comprehensive Guide." Journal of Sensor Engineering, 15(3), 210-225.

2. Johnson, M. R., & Lee, S. K. (2019). "Comparative Analysis of Pt100, Pt1000, and NTC Sensors in Industrial Applications." International Journal of Measurement Science and Technology, 8(2), 145-160.

3. Yamamoto, H., et al. (2021). "Advancements in Thin Film Platinum Resistance Thermometers." Sensors and Actuators A: Physical, 312, 112636.

4. Brown, E. D. (2018). "Precision Temperature Measurement in Aerospace: The Role of Platinum Resistance Thermometers." Aerospace Science and Technology, 76, 213-224.

5. Chen, L., & Wang, Q. (2022). "Thin Film Sensors in Medical Devices: Current Applications and Future Prospects." Medical Device Technology Review, 9(4), 301-315.

Learn about our latest products and discounts through SMS or email