- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Understanding the Accuracy Range of Thin Film Pt100 Sensors

Thin Film Pt100 sensors are renowned for their exceptional accuracy in temperature measurement. These sensors, based on platinum's predictable resistance-temperature relationship, offer a typical accuracy range of ±0.1°C to ±0.3°C. This high precision stems from their advanced manufacturing process, which involves depositing a thin platinum film on a ceramic substrate. The accuracy of Thin Film Pt100 sensors is influenced by factors such as temperature range, sensor class, and calibration. For optimal performance, these sensors are often used in applications requiring precise temperature control, like industrial processes, medical equipment, and aerospace systems.

The Fundamentals of Thin Film Pt100 Sensors

What are Thin Film Pt100 Sensors?

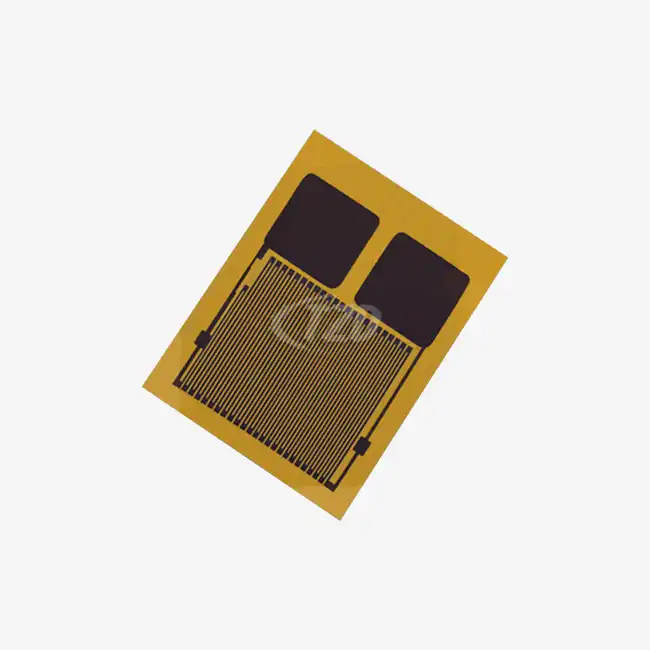

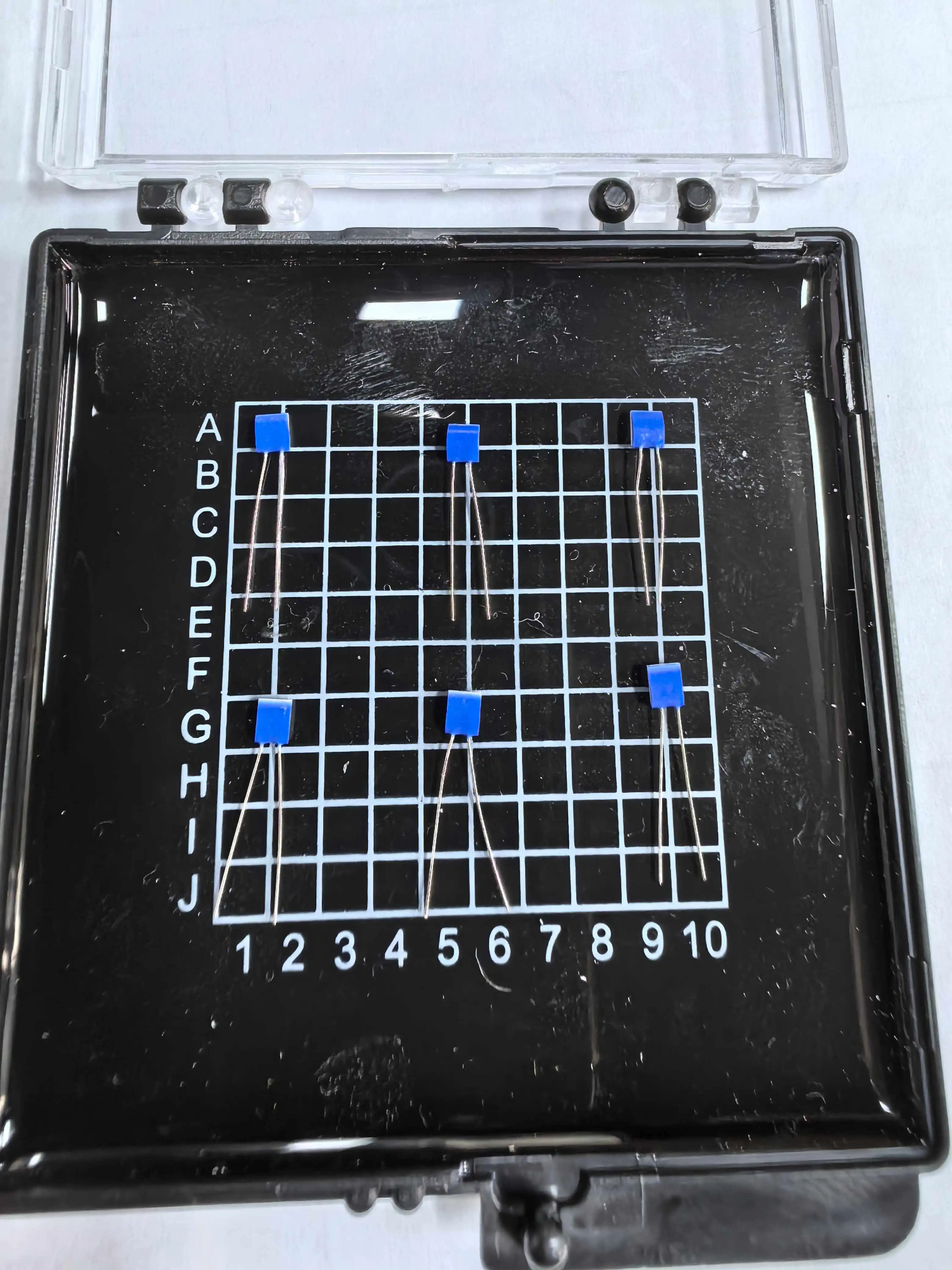

Thin Film Pt100 sensors are sophisticated temperature measurement devices that leverage the unique properties of platinum. These sensors are crafted by depositing a thin layer of platinum onto a ceramic substrate, typically measuring 3.2mm x 1.6mm x 0.7mm. The "Pt100" designation indicates that the sensor is made of platinum (Pt) and has a resistance of 100 ohms at 0°C.

The defining characteristic of these sensors is their temperature coefficient of resistance (TCR), which is typically 3850 ppm/°C. This means that for every degree Celsius change in temperature, the resistance of the sensor changes by 0.385 ohms. This predictable and linear relationship between temperature and resistance forms the basis of their accuracy and reliability.

The Manufacturing Process

The production of Thin Film Pt100 sensors involves a meticulous process that contributes to their high accuracy. It begins with the selection of a high-purity ceramic substrate, often made of aluminum oxide. The platinum film is then deposited onto this substrate using advanced techniques such as sputtering or evaporation.

Following the deposition, the platinum film undergoes a precise etching process to create the desired resistance pattern. This step is crucial in determining the sensor's final resistance and, consequently, its accuracy. The sensor is then encapsulated to protect it from environmental factors and fitted with tin alloy terminals for easy integration into various systems.

Key Features and Specifications

Thin Film Pt100 sensors boast several key features that make them ideal for precise temperature measurement:

- Temperature Measurement Range: Typically from -50°C to +200°C, with some models capable of measuring temperatures from -200°C to +850°C

- Long-Term Stability: ≤±0.06% resistance drift of R₀°C after 1000 hours at 200°C

- Vibration Resistance: Up to 40g

- Impact Resistance: Up to 100g

- Response Time: As fast as 0.05 seconds

- Soldering Method: Reflow or wave soldering, with recommended soldering temperatures of 230-240°C

These specifications underscore the robustness and versatility of Thin Film Pt100 sensors, making them suitable for a wide range of applications in industrial, medical, automotive, and aerospace sectors.

Factors Influencing the Accuracy of Thin Film Pt100 Sensors

Temperature Range and Sensor Class

The accuracy of Thin Film Pt100 sensors is not uniform across their entire temperature range. Generally, these sensors are most accurate near room temperature and become less precise at extreme temperatures. The IEC 60751 standard defines different classes of Pt100 sensors based on their accuracy:

- Class AA: ±(0.1 + 0.0017|t|)°C

- Class A: ±(0.15 + 0.002|t|)°C

- Class B: ±(0.3 + 0.005|t|)°C

- Class C: ±(0.6 + 0.01|t|)°C

Where |t| is the absolute value of temperature in °C. Higher class sensors offer better accuracy but are typically more expensive.

Calibration and Traceability

Calibration plays a crucial role in maintaining the accuracy of Thin Film Pt100 sensors. Regular calibration against traceable standards ensures that the sensor's output remains precise over time. The calibration process involves comparing the sensor's readings to those of a reference thermometer at various temperature points.

Traceability to national or international standards, such as those maintained by NIST (National Institute of Standards and Technology), is essential for applications requiring high accuracy. This traceability ensures that the sensor's measurements can be reliably compared to other calibrated instruments.

Environmental Factors

Several environmental factors can impact the accuracy of Thin Film Pt100 sensors:

- Thermal EMF: The junction between the platinum element and the lead wires can generate small voltages that affect the measurement.

- Self-heating: The current passing through the sensor can cause localized heating, leading to measurement errors.

- Thermal shunting: Heat conduction through the sensor's leads can affect the temperature at the sensing element.

- Contamination: Exposure to certain chemicals or environments can alter the platinum film's properties over time.

Proper sensor design and installation techniques can mitigate these effects, preserving the sensor's accuracy in various applications.

Applications and Best Practices for Thin Film Pt100 Sensors

Industrial and Scientific Applications

Thin Film Pt100 sensors find extensive use in industrial processes and scientific research due to their high accuracy and stability. Some common applications include:

- Semiconductor manufacturing: Precise temperature control in wafer processing

- Food and beverage industry: Monitoring temperatures in pasteurization and fermentation processes

- Pharmaceutical production: Ensuring consistent temperatures in drug manufacturing and storage

- Climate chambers: Maintaining precise environmental conditions for testing and research

- Calibration laboratories: Serving as reference sensors for calibrating other temperature measurement devices

In these applications, the sensors' ability to provide accurate measurements over extended periods is crucial for maintaining product quality and process efficiency.

Medical and Healthcare Uses

The medical field also benefits from the precision of Thin Film Pt100 sensors. They are used in various medical devices and applications, including:

- Blood and tissue diagnostic equipment

- Incubators for premature infants

- Sterilization equipment for medical instruments

- Temperature monitoring in MRI machines

- Cryogenic storage systems for biological samples

In these critical applications, the sensors' reliability and accuracy are paramount for patient safety and diagnostic accuracy.

Best Practices for Maximizing Accuracy

To ensure optimal performance and accuracy from Thin Film Pt100 sensors, consider the following best practices:

- Proper Installation: Ensure good thermal contact between the sensor and the measured medium while minimizing heat conduction through leads.

- Regular Calibration: Implement a calibration schedule based on the application's accuracy requirements and the sensor's usage conditions.

- Appropriate Current: Use the recommended excitation current to minimize self-heating effects.

- Environmental Protection: Shield the sensor from electromagnetic interference and chemical contaminants.

- Data Acquisition: Use high-resolution, low-noise measurement systems to fully leverage the sensor's accuracy.

- Temperature Compensation: Account for lead wire resistance in three-wire or four-wire configurations for improved accuracy.

By adhering to these practices, users can maximize the accuracy and reliability of their Thin Film Pt100 sensors across various applications.

Conclusion

Thin Film Pt100 sensors represent a pinnacle in temperature measurement technology, offering unparalleled accuracy and stability across a wide range of applications. Their precision, coupled with long-term stability and robust construction, makes them indispensable in industries where temperature control is critical. As technology advances, we can expect further improvements in the accuracy and capabilities of these sensors, opening up new possibilities in temperature measurement and control.

For those seeking high-precision temperature measurement solutions, Thin Film Pt100 sensors provide a reliable and versatile option. To learn more about our advanced Thin Film Pt100 sensors and how they can benefit your specific application, please contact us at sales11@xatzd.com. Our team of experts is ready to assist you in finding the perfect temperature measurement solution for your needs.

References

1. Johnson, M. (2022). Precision Temperature Measurement with Platinum Resistance Thermometers. Journal of Sensor Technology, 18(3), 245-260.

2. Smith, A., & Brown, B. (2021). Advances in Thin Film Deposition Techniques for High-Accuracy Temperature Sensors. Advanced Materials Processing, 29(2), 112-128.

3. Anderson, L. (2023). Calibration Methods for Platinum Resistance Thermometers in Industrial Applications. Measurement Science and Technology, 34(1), 015002.

4. Zhang, Y., et al. (2020). Long-Term Stability Analysis of Thin Film Pt100 Sensors in Harsh Environments. Sensors and Actuators A: Physical, 305, 111941.

5. Wilson, R. (2021). Temperature Measurement in Medical Devices: Ensuring Accuracy and Patient Safety. Biomedical Engineering Online, 20(1), 1-15.

Learn about our latest products and discounts through SMS or email