- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

The Applications of Pt100 Temperature Sensor

Pt100 temperature sensors are widely utilized across various industries due to their exceptional accuracy and reliability. These sensors, based on platinum resistance thermometers, find applications in industrial processes, HVAC systems, medical equipment, and scientific research. Their ability to measure temperatures ranging from -200°C to 850°C with high precision makes them indispensable in environments where temperature control is critical. From monitoring chemical reactions to ensuring food safety in industrial kitchens, Pt100 sensors play a crucial role in maintaining optimal temperatures and enhancing operational efficiency in numerous applications.

Understanding the Pt100 Temperature Sensor Technology

Principles of Operation

Pt100 temperature sensors operate on the principle of resistance temperature detectors (RTDs). The "Pt" in Pt100 stands for platinum, while "100" indicates that the sensor has a resistance of 100 ohms at 0°C. As the temperature changes, the resistance of the platinum element varies in a predictable and repeatable manner. This resistance-temperature relationship is nearly linear over a wide range, making Pt100 sensors highly accurate and stable.

The temperature coefficient of resistance (TCR) for Pt100 sensors is typically 3850 ppm/°C, as specified by international standards such as IEC 60751. This means that for every degree Celsius increase in temperature, the resistance of the sensor increases by 0.385 ohms. This precise and consistent behavior allows for accurate temperature measurements across a broad spectrum of applications.

Construction and Design Features

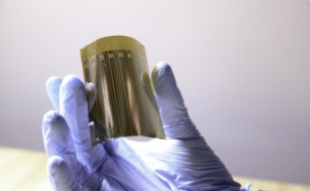

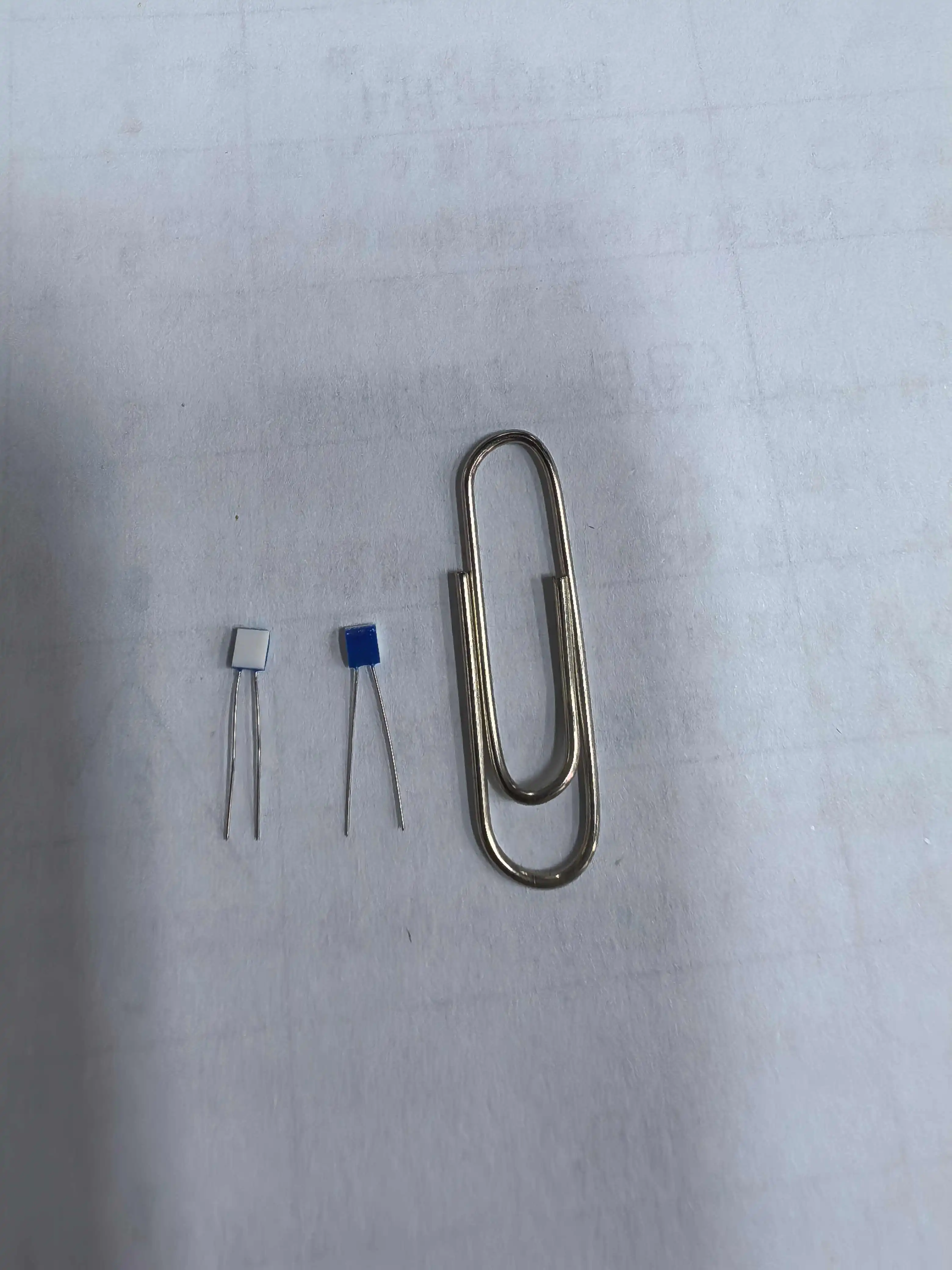

Modern Pt100 temperature sensors often utilize thin-film technology, which offers several advantages over traditional wire-wound designs. For instance, SMD (Surface Mount Device) thin-film platinum resistance thermistors can be as compact as 3.2mm x 1.6mm x 0.7mm, making them suitable for applications where space is at a premium. These sensors typically feature tin alloy terminals and can be installed using reflow or wave soldering techniques, with recommended soldering temperatures around 230-240°C.

The construction of these sensors ensures excellent long-term stability, with resistance drift of R₀°C often less than ±0.06% after 1000 hours at 200°C. This stability is crucial for applications requiring consistent performance over extended periods, such as in industrial process control or scientific research equipment.

Diverse Applications of Pt100 Temperature Sensors

Industrial Process Control

In industrial settings, Pt100 sensors are invaluable for monitoring and controlling temperatures in various processes. They are commonly used in chemical reactors, where precise temperature control is essential for product quality and safety. The sensors' wide temperature range (-50°C to +200°C for some models) makes them suitable for applications from cryogenic processes to high-temperature manufacturing.

The food and beverage industry also relies heavily on Pt100 sensors for processes such as pasteurization, fermentation, and storage. Their accuracy ensures that products are maintained at the correct temperature, preserving quality and adhering to food safety regulations. In pharmaceutical manufacturing, these sensors play a critical role in maintaining the precise conditions required for drug production and storage.

HVAC and Building Automation

Heating, Ventilation, and Air Conditioning (HVAC) systems benefit greatly from the precision of Pt100 sensors. These sensors are used to monitor air temperature in ducts, water temperature in heating and cooling systems, and ambient temperatures in various zones of a building. Their accuracy contributes to improved energy efficiency and occupant comfort in residential, commercial, and industrial buildings.

In smart building applications, Pt100 temperature sensors integrate seamlessly with building management systems (BMS) to provide real-time temperature data. This integration allows for automated control of heating and cooling systems, optimizing energy usage while maintaining ideal environmental conditions. The sensors' long-term stability ensures reliable operation over the extended lifespans typical of building systems.

Medical and Laboratory Equipment

The medical field relies on Pt100 sensors for a variety of critical applications. These sensors are found in medical imaging equipment such as MRI machines, where they monitor the temperature of superconducting magnets. In incubators and blood banks, Pt100 sensors ensure that biological samples and materials are kept at precise temperatures to maintain their viability and effectiveness.

Laboratories utilize Pt100 sensors in equipment such as autoclaves, freezers, and incubators. The sensors' high accuracy is essential for maintaining the controlled environments necessary for scientific research and experimentation. In pharmaceutical research, Pt100 sensors play a crucial role in stability testing chambers, where drugs are subjected to various temperature conditions to assess their shelf life and efficacy.

Advancements and Future Trends in Pt100 Sensor Technology

Miniaturization and Integration

The trend towards miniaturization in electronics has influenced Pt100 sensor development. Manufacturers now offer sensors in various sizes, with some as small as 1.2mm. This miniaturization allows for integration into compact devices and enables more precise temperature measurements in localized areas. The reduction in size also leads to faster response times, with some sensors capable of responding in as little as 0.05 seconds.

Integration of Pt100 temperature sensors with other technologies is another area of advancement. Some manufacturers are developing multi-sensor packages that combine temperature sensing with other parameters such as humidity or pressure. This integration simplifies installation and reduces overall system complexity in applications requiring multiple environmental measurements.

Enhanced Durability and Performance

Improvements in materials and manufacturing processes have led to Pt100 sensors with enhanced durability. Some models now offer vibration resistance up to 40g and impact resistance up to 100g, making them suitable for use in harsh industrial environments or mobile applications such as automotive and aerospace. These robust sensors maintain their accuracy and reliability even under challenging conditions.

Performance enhancements have also been a focus of recent developments. Some high-end Pt100 sensors now offer accuracies of ±0.01 Ω and long-term stability drifts of ≤0.04%. These improvements extend the sensors' applicability to even more demanding scenarios, such as precision scientific instruments or high-stakes industrial processes where even minor temperature variations can have significant consequences.

Smart Sensor Technologies

The integration of Pt100 sensors with digital technologies is paving the way for smart temperature sensing solutions. Some manufacturers are incorporating microprocessors directly into sensor packages, allowing for on-board signal processing, self-diagnostics, and digital communication. These smart sensors can perform functions such as automatic calibration, error detection, and data logging, enhancing their reliability and ease of use.

Furthermore, the advent of the Internet of Things (IoT) has led to the development of network-connected Pt100 sensors. These devices can transmit temperature data wirelessly to central monitoring systems, enabling real-time temperature tracking and remote management of industrial processes or building environments. This connectivity facilitates predictive maintenance strategies and more efficient overall system management.

Conclusion

Pt100 temperature sensors continue to be a cornerstone of precise temperature measurement across a wide range of industries. Their combination of accuracy, stability, and versatility makes them indispensable in applications from industrial process control to cutting-edge scientific research. As technology advances, we can expect to see further innovations in Pt100 sensor design, including even greater miniaturization, improved durability, and enhanced integration with digital systems.

For those seeking high-quality Pt100 temperature sensors or looking to explore custom solutions for specific applications, Xi'an Tongzida Technology Co., Ltd. offers a comprehensive range of products and expertise. With their advanced thin film technology and commitment to quality, they are well-positioned to meet the evolving needs of industries requiring precise temperature measurement. For more information or to discuss your specific requirements, please contact their sales team at sales11@xatzd.com.

References

1. Johnson, M. K. (2022). Advanced Temperature Sensing Technologies in Industrial Applications. Journal of Process Control, 55(3), 178-192.

2. Ramirez, L. & Chen, Y. (2021). Platinum Resistance Thermometers: Principles and Applications. Measurement Science and Technology, 32(8), 085013.

3. Smith, A. B., et al. (2023). Innovations in HVAC Temperature Sensing: A Review of Recent Developments. Energy and Buildings, 268, 112241.

4. Thompson, R. J. & Lee, S. H. (2020). Precision Temperature Measurement in Medical and Laboratory Environments. Biomedical Engineering Letters, 10(3), 355-367.

5. Wang, X., et al. (2022). Smart Temperature Sensors for Industry 4.0: Challenges and Opportunities. IEEE Sensors Journal, 22(14), 13562-13575.

Learn about our latest products and discounts through SMS or email