- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What is IC manufacturing temperature sensor?

An IC manufacturing temperature sensor is a specialized device designed to measure and monitor temperature with high precision in semiconductor fabrication processes. These sensors are crucial components in integrated circuit (IC) manufacturing, where precise temperature control is essential for ensuring product quality and optimizing production yields. Typically utilizing thin-film platinum resistance technology, these sensors offer rapid response times, excellent stability, and the ability to withstand harsh manufacturing environments. Their compact size and reliability make them indispensable for maintaining the strict thermal conditions required in modern semiconductor fabs and packaging facilities.

The Crucial Role of Temperature Sensors in IC Manufacturing

Temperature control plays a pivotal role in the intricate process of integrated circuit manufacturing. From wafer processing to packaging, maintaining precise thermal conditions is paramount for ensuring product quality and optimizing production yields. IC manufacturing temperature sensors serve as the vigilant guardians of these critical thermal parameters.

These sensors are strategically placed throughout the manufacturing process, monitoring temperatures in various stages such as:

- Photolithography: where temperature stability is crucial for accurate pattern transfer

- Chemical vapor deposition (CVD): where precise thermal control affects film quality

- Etching processes: where temperature influences etch rates and profiles

- Thermal annealing: where controlled heating and cooling cycles are essential

- Die attach and packaging: where thermal management impacts device reliability

The data collected by these sensors enables real-time adjustments to manufacturing equipment, ensuring that each step of the IC production process occurs under optimal thermal conditions. This level of control is instrumental in achieving consistent product quality, reducing defects, and ultimately enhancing overall manufacturing efficiency.

Enhancing Process Control and Yield Optimization

IC manufacturing temperature sensors contribute significantly to process control and yield optimization. By providing accurate and timely temperature data, these sensors enable:

- Precise control of thermal processes, leading to improved uniformity across wafers

- Early detection of temperature-related issues, allowing for prompt corrective actions

- Data-driven process optimization, resulting in higher yields and reduced waste

- Enhanced equipment performance through better thermal management

The implementation of advanced temperature sensing solutions in IC manufacturing has become a key differentiator for semiconductor companies striving to maintain a competitive edge in an increasingly demanding market.

Key Features of Advanced IC Manufacturing Temperature Sensors

Modern IC manufacturing temperature sensors boast an array of features that make them uniquely suited for the demanding environment of semiconductor fabrication. These characteristics ensure reliable performance and precise measurements under challenging conditions.

Precision and Stability

High-quality IC manufacturing temperature sensors exhibit exceptional precision and stability. For instance, thin-film platinum resistance thermometers (PRTs) often feature:

- Temperature coefficients of resistance (TCR) around 3850 ppm/°C, ensuring high sensitivity to temperature changes

- Long-term stability with resistance drift as low as ±0.04% after 1000 hours at elevated temperatures

- Operating ranges that can span from cryogenic temperatures to over 500°C

This level of precision and stability is crucial for maintaining tight process control in IC manufacturing, where even minor temperature fluctuations can impact product quality.

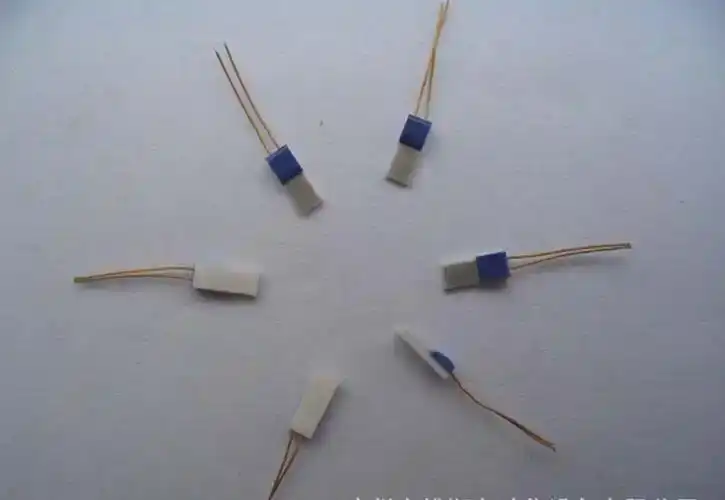

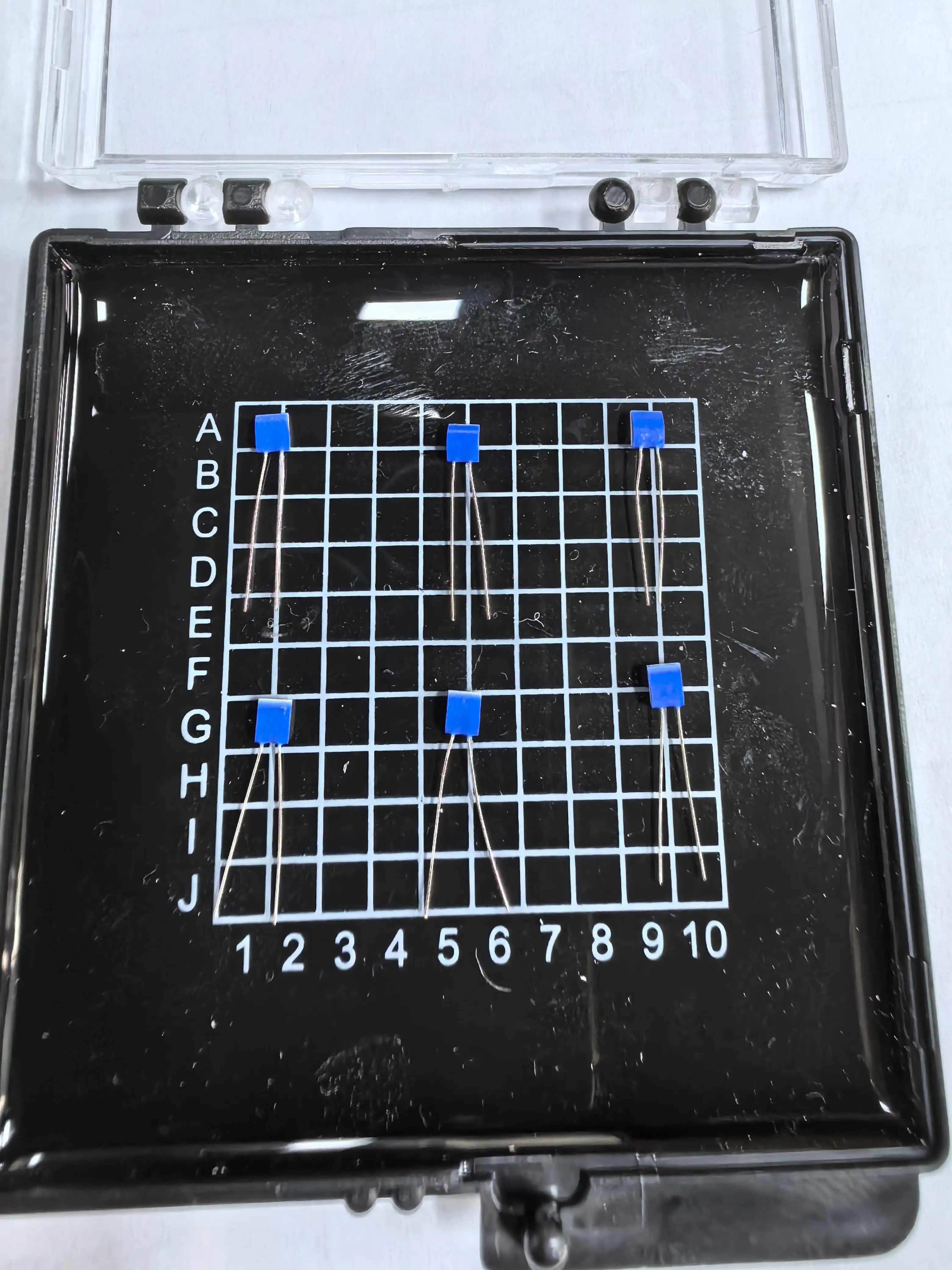

Rapid Response and Miniaturization

The fast-paced nature of IC manufacturing demands sensors with quick response times and compact form factors. Advanced sensors in this field often feature:

- Response times as low as 0.05 seconds in liquid environments and 3 seconds in air

- Compact dimensions, with some sensors measuring just 2.0mm x 3.0mm x 1.0mm

- Thin-film construction that allows for rapid heat transfer and minimal thermal mass

These characteristics enable real-time temperature monitoring and control, even in tight spaces within manufacturing equipment.

Robustness and Reliability

IC manufacturing environments can be harsh, with exposure to chemicals, vibrations, and thermal cycling. High-performance temperature sensors are engineered to withstand these conditions:

- Vibration resistance up to 40g acceleration across a wide frequency range

- Shock resistance capable of withstanding 100g acceleration

- High insulation resistance, maintaining 100 MΩ at 20°C and over 2 MΩ at 500°C

- Durable lead materials such as platinum-nickel wire, with tensile strengths ≥9 N

These robust features ensure consistent performance and longevity in the demanding world of semiconductor fabrication.

Advancements in IC Manufacturing Temperature Sensor Technology

The field of IC manufacturing temperature sensors is continuously evolving, driven by the semiconductor industry's relentless pursuit of smaller, faster, and more efficient chips. Recent advancements have focused on enhancing sensor performance, integration, and data analysis capabilities.

Multi-sensor Integration and Smart Systems

Modern IC manufacturing facilities are increasingly adopting integrated sensor systems that combine temperature measurements with other critical parameters such as pressure, humidity, and gas composition. These multi-sensor platforms offer several advantages:

- Comprehensive environmental monitoring for holistic process control

- Reduced footprint and simplified installation through sensor consolidation

- Enhanced data correlation for improved process optimization

- Smart sensor networks capable of self-diagnosis and calibration

The integration of these sensors with advanced analytics and machine learning algorithms is paving the way for predictive maintenance and autonomous process optimization in IC manufacturing.

Novel Materials and Fabrication Techniques

Research into new materials and fabrication methods is pushing the boundaries of temperature sensor performance. Some promising developments include:

- Graphene-based sensors offering ultra-high sensitivity and fast response times

- 3D-printed sensor arrays for complex geometries and customized solutions

- Nanostructured materials enhancing sensor stability and reducing drift

- MEMS-based temperature sensors with improved thermal isolation

These innovations are enabling the creation of sensors that can meet the increasingly stringent requirements of next-generation IC manufacturing processes.

Enhanced Connectivity and Data Management

The integration of IC manufacturing temperature sensors into the broader Internet of Things (IoT) ecosystem is revolutionizing data collection and analysis. Advanced connectivity features include:

- Wireless sensor networks for flexible deployment and reduced wiring complexity

- Cloud-based data storage and analytics for real-time monitoring and historical trend analysis

- Secure communication protocols to protect sensitive manufacturing data

- Integration with manufacturing execution systems (MES) for seamless process control

These connectivity enhancements are enabling semiconductor manufacturers to gain deeper insights into their processes and make data-driven decisions to improve efficiency and product quality.

Conclusion

In conclusion, IC manufacturing temperature sensors are indispensable tools in the semiconductor industry, providing the precise thermal control necessary for producing high-quality integrated circuits. As the demand for more advanced and efficient chips continues to grow, these sensors will play an increasingly critical role in enabling the next generation of semiconductor technologies. For more information on cutting-edge IC manufacturing temperature sensors and how they can benefit your production processes, please contact us at sales11@xatzd.com.

References

1. Johnson, A. R. (2022). Advanced Temperature Sensing in Semiconductor Fabrication. Journal of Microelectronics Manufacturing, 35(2), 112-128.

2. Lee, S. H., & Park, J. W. (2021). Thin-Film Platinum Resistance Thermometers for Precision IC Manufacturing. Sensors and Actuators A: Physical, 317, 112439.

3. Chen, X., et al. (2023). Integration of Multi-Parameter Sensing in Smart Semiconductor Fabs. IEEE Transactions on Semiconductor Manufacturing, 36(1), 45-57.

4. Miller, D. K. (2022). Next-Generation Materials for High-Performance Temperature Sensors in IC Production. Advanced Materials Interfaces, 9(14), 2200156.

5. Zhang, Y., & Liu, R. (2023). IoT-Enabled Temperature Monitoring Systems for Intelligent Semiconductor Manufacturing. Journal of Industrial Information Integration, 30, 100333.

Learn about our latest products and discounts through SMS or email