- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What to choose for industrial temperature measurement? Pt100 SMD thin film platinum resistor is precise and stable!

In industrial production, the accuracy of temperature measurement directly affects product quality and production safety. Faced with numerous sensor options, why has Pt100 SMD thin film platinum resistance become a popular choice in the industry? This article comprehensively analyzes performance, application, selection, and other dimensions to help you quickly identify highly adaptable temperature measurement solutions.

H2: Pt100-SMD thin film platinum resistor, the performance benchmark for industrial temperature measurement

H3: Wide temperature range coverage, suitable for complex industrial environments

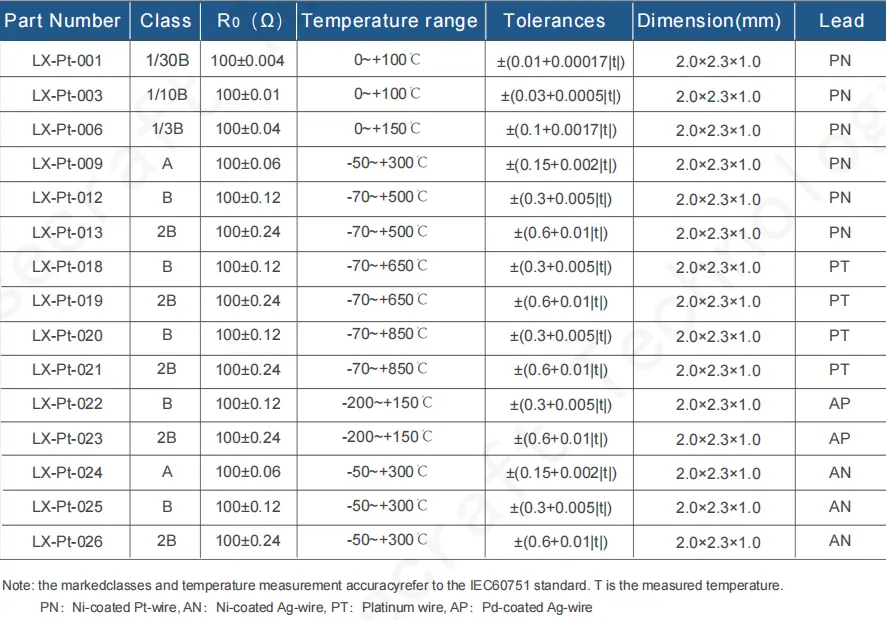

The temperature environment in industrial settings is constantly changing, from low-temperature storage to high-temperature production processes, requiring extremely high temperature adaptability of sensors. The temperature measurement range of Pt100 SMD is -50 ℃~+200 ℃, and some models support special requirements of 0~+150 ℃. It can easily meet the temperature measurement needs of different scenarios such as industrial furnaces, production line equipment, and storage environments, without the need for frequent sensor replacement.

H3: High precision+low drift, reliable and error free data

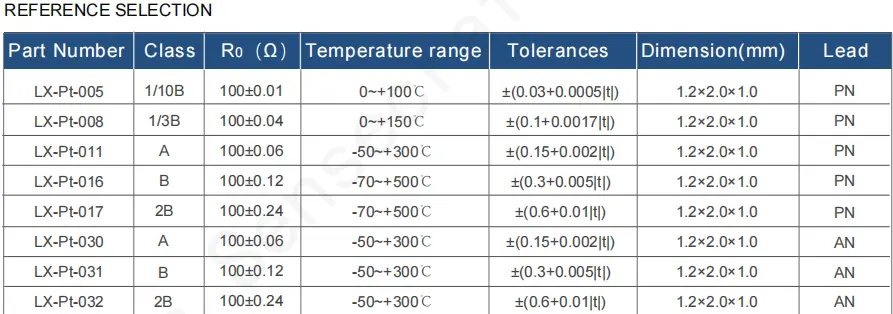

Industrial production has strict requirements for the accuracy of temperature data. Pt100 SMD follows the DIN EN 60751 standard and is divided into three accuracy levels: A, B, and 2B. The tolerance ranges are ± (0.15+0.002 | t |), ± (0.3+0.005 | t |), and ± (0.6+0.01 | t |), which can accurately capture subtle temperature changes. At the same time, its long-term stability is excellent, with a resistance drift of ≤ 0.06% after 1000 hours at 200 ℃, ensuring reliable data during long-term production and avoiding product defects caused by measurement errors.

H3: Strong process compatibility, suitable for automated production

Modern industrial production lines are mainly automated, and Pt100 SMD supports various soldering processes such as reflow soldering and wave soldering. It is recommended to use high-temperature solder paste for soldering at 230-240 ℃, which can seamlessly integrate into the automated production process and greatly improve assembly efficiency. Compared to traditional lead type sensors, its SMD packaging design is more convenient for batch installation and reduces labor costs.

H2: Technical details of Pt100-SMD, understanding core competitiveness

H3: Resistance characteristics and calculation formula

The Ro (0 ℃) resistance of Pt100 SMD is 100 Ω, and the temperature coefficient of resistance is 3850ppm/℃. The resistance temperature relationship strictly follows the DIN EN 60751 standard formula. When t ≥ 0 ℃, R (t)=Ro * (1+At+Bt ²) (A=3.9083 × 10 ³ ℃⁻¹, B=-5.775 × 10 ⁻⁷℃⁻²); When t<0 ℃, R (t)=Ro * (1+At+Bt ²+C * (t-100 ℃)) * t ³ (C=-4.183 × 10 ⁻¹² ℃⁻⁴), ensuring measurement accuracy across the entire temperature range.

H3: Structure and Packaging Design

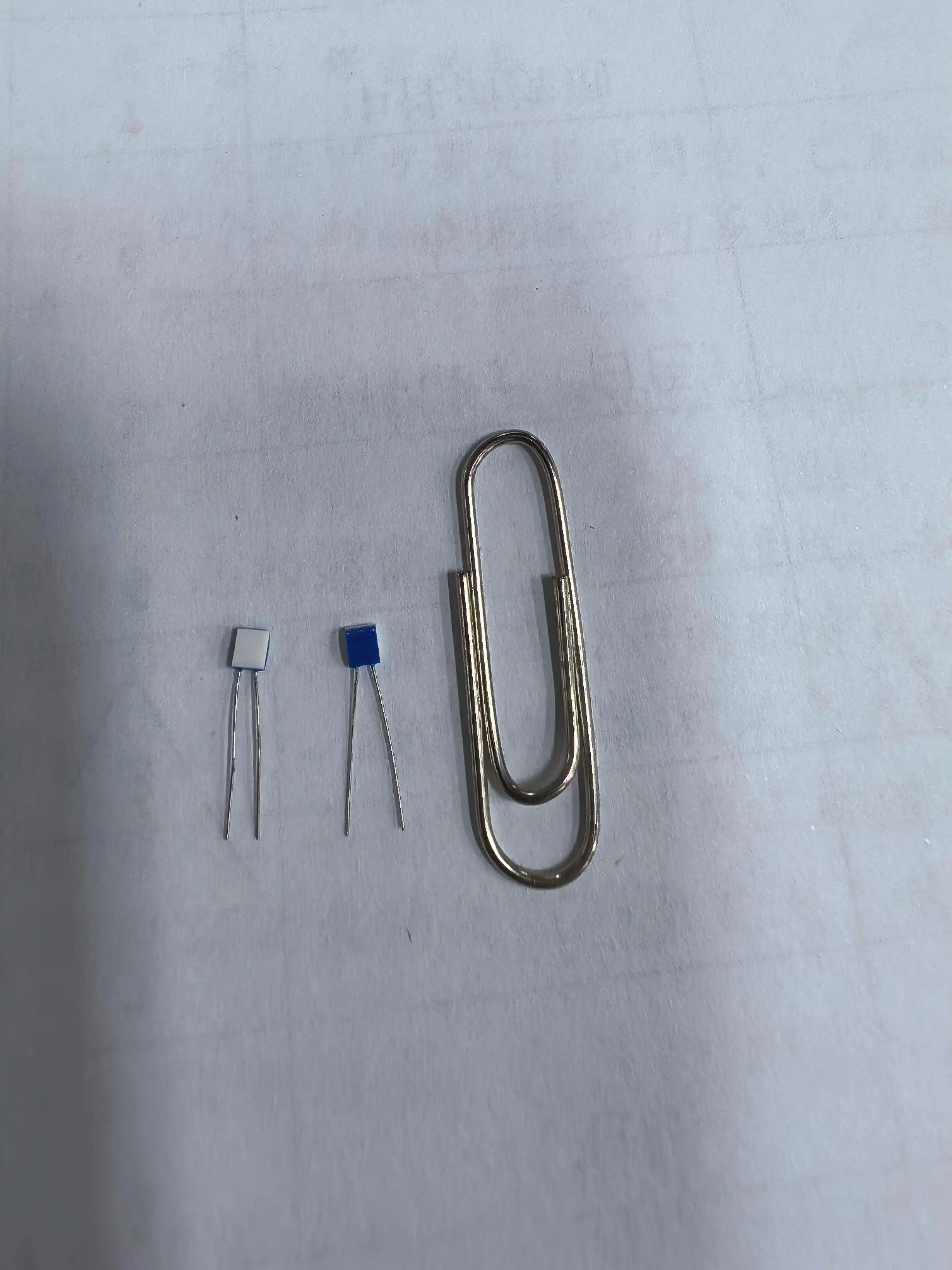

The component size of Pt100 SMD is only 3.2 × 1.6 × 0.7mm, which is compact and does not occupy too much equipment space, making it easy to integrate into various industrial equipment. The product adopts tin alloy terminals, which have good welding conductivity and high firmness; The packaging is vacuum plastic packaging, which can effectively prevent moisture and oxidation. Each package contains 1000 pieces, with a minimum order quantity of 1000 pieces. It supports customized packaging to meet bulk procurement needs.

H2: Specific application cases of Pt100-SMD in the industrial field

H3: Industrial furnace temperature monitoring

Industrial furnaces are the core equipment in industries such as metal processing and ceramic firing, and the uniformity of furnace temperature directly affects product quality. Pt100 SMD is installed at key positions inside the furnace, which can monitor temperature changes in real time. Its wide temperature range and high precision ensure that the furnace temperature is controlled within the set range, reducing product scrap rate. Meanwhile, its excellent long-term stability avoids frequent shutdown calibration and improves production efficiency.

H3: Temperature control of production line equipment

In production lines such as electronic component welding and automotive parts processing, high operating temperatures of equipment may lead to component damage. Pt100 SMD is integrated into the temperature control module of the device, providing real-time feedback on temperature data. When the temperature exceeds the threshold, a cooling mechanism is triggered in a timely manner to ensure the safe operation of the device. Its multiple welding methods are adaptable to the assembly needs of different production lines, with strong compatibility.

H3: Temperature monitoring of storage environment

For industrial warehouses that require strict temperature control, such as chemical raw materials and electronic component warehouses, Pt100 SMD can accurately monitor the temperature of the storage environment to ensure that materials are not affected by high or low temperatures. Its compact size makes it easy to install on storage shelves, ventilation openings, and other locations. The vacuum packaging design makes it less susceptible to moisture damage in storage environments and has a longer service life.

H2: PT100-SMD Selection Guide for Avoiding Pits, Matching on Demand without Waste

H3: Select according to accuracy requirements

High precision scenarios (such as laboratory equipment, precision manufacturing): Select A-grade model Pt100. SMD. M150.1206. A (code LX-Pt-057), Ro (0 ℃) resistance tolerance of 100 ± 0.06 Ω, with the smallest measurement error.

Conventional industrial scenario: Choose the B-grade model Pt100. SMD. M200.1206. B (code LX-Pt-058), with a Ro (0 ℃) resistance tolerance of 100 ± 0.12 Ω, balancing accuracy and cost.

Batch low-cost scenario: Choose the 2B grade model Pt100.SMD.M200.1206.2B (code LX-Pt-059), with a Ro (0 ℃) resistance tolerance of 100 ± 0.24 Ω, suitable for batch applications with moderate precision requirements.

H3: Select based on temperature measurement range

0~+150 ℃ scenario: Choose M150 type, suitable for industrial environments that do not require low-temperature measurement (such as normal temperature production lines, ordinary warehouses).

-50~+200 ℃ scenario: Choose M200 type, suitable for wide temperature range requirements such as low-temperature storage and high-temperature production, with a wider range of applications.

FAQ

Q1: Can PT100-SMD work for a long time in high temperature environments?

A: Okay. Its maximum working temperature is 200 ℃, and after continuous operation for 1000 hours at this temperature, the resistance drift is ≤ 0.06%. It has excellent long-term stability and is suitable for high-temperature industrial scenarios.

Q2: What should be paid attention to when welding?

A: It is recommended to use high-temperature solder paste and control the soldering temperature at 230-240 ℃. Reflow soldering or wave soldering should be used to avoid damaging the sensor due to high temperature. After soldering, it is necessary to check whether the terminal connection is firm.

Q3: What is the minimum order quantity? Can we purchase in small quantities?

A: The standard minimum order quantity is 1000 pieces, and the packaging is 1000 pieces per pack; If you need small batch procurement, you can contact Xi'an Tongzida Technology Co., Ltd. to negotiate customization.

Q4: What are the advantages of Pt100-SMD compared to traditional lead type platinum resistors?

A: Pt100 SMD has lower cost, supports multiple automated soldering processes, and has high installation efficiency; Smaller size for easy integration; Packaging is more moisture-proof, has a longer service life, and is more suitable for modern industrial production needs.

Q5: How to obtain technical support?

A: You can consult technical issues, obtain selection guidance and product manuals through Xi'an Tongzida Technology Co., Ltd.

References

Xi'an Tongzida Technology Co., Ltd Pt100 SMD Technical Specification (Version V2.0)

DIN EN 60751 standard. General technical specifications for industrial thin-film platinum resistance temperature sensors

In the field of industrial temperature measurement, Pt100 SMD thin film platinum resistors have become the preferred choice for many enterprises due to their wide temperature range, high precision, and strong compatibility. Whether you need to improve product quality or optimize production efficiency, Pt100 SMD can provide reliable temperature measurement solutions. Contact Xi'an Tongzida Technology Co., Ltd. immediately to inquire about selection details and bulk purchase prices, and let precise temperature measurement help your industrial production take it to the next level!

Author information

Author: Xi'an Tongzida Technology Marketing Department Introduction: Focused on promoting the industrial sensor market and providing technical services, we have a deep understanding of temperature measurement needs in various industries and are committed to recommending highly adaptable and cost-effective sensor products to customers.

Xi'an Tongzeda Technology Co., Ltd. is a leading manufacturer and supplier of advanced thermistor technology, focusing on providing high-performance temperature sensors for demanding industrial applications. We have profound expertise in microsensor manufacturing, specific packaging technologies, and multi-sensor integration methods, which ensures the excellent performance and reliability of our thermistors. As a trusted supplier of precision temperature measurement solutions, we offer a complete thermistor system, including sensor chips, testing systems, and analysis software. Please feel free to contact our technical experts at any time. ventes11@xatzd.com Discuss your specific requirements for thermistors and learn how our advanced thermal resistor optimization and manufacturing capabilities can enhance the performance and reliability of your temperature measurement system.

Learn about our latest products and discounts through SMS or email