Understanding the Pt1000 Sensor: Principles and Advantages

The Fundamentals of Platinum Resistance Thermometry

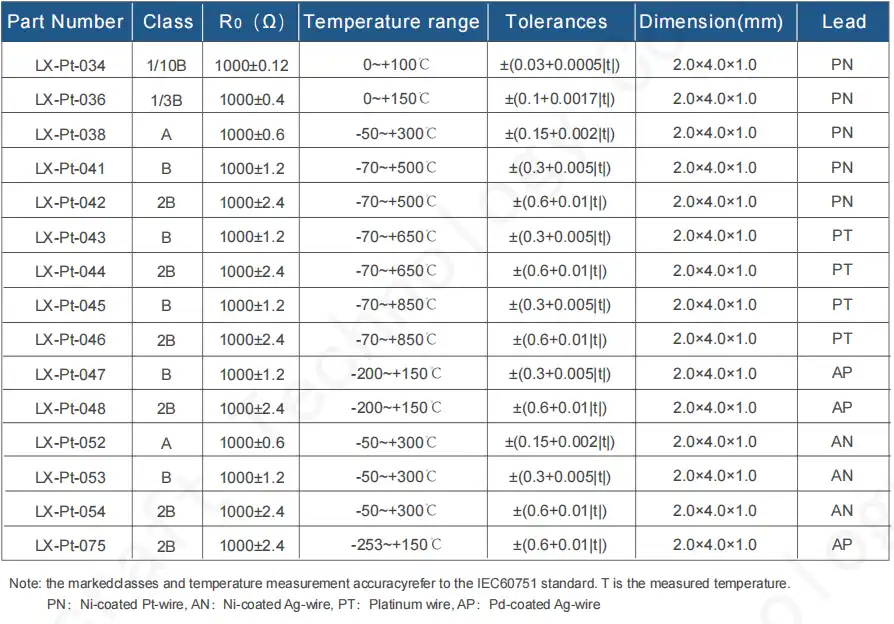

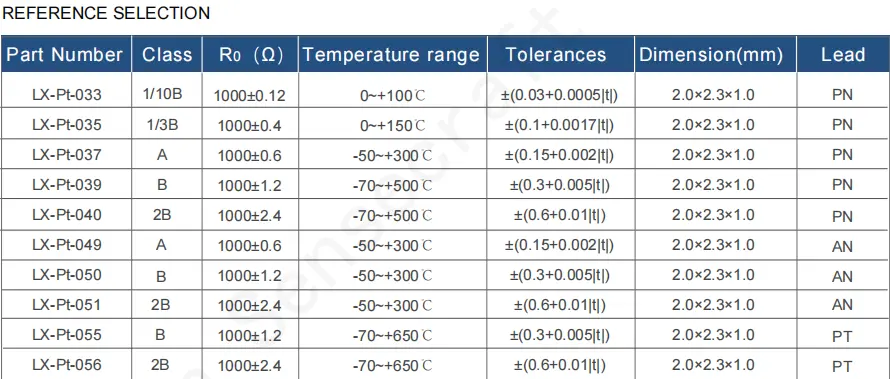

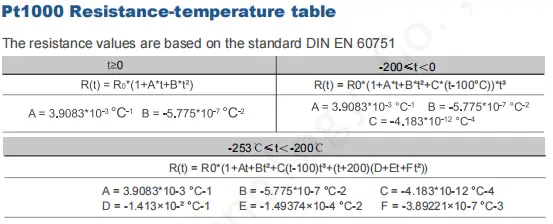

Platinum resistance thermometers, such as the Pt1000 sensor, operate on the principle that the electrical resistance of platinum changes predictably with temperature. This relationship is nearly linear over a wide temperature range, making platinum an ideal material for temperature sensing. The "1000" in Pt1000 refers to the sensor's nominal resistance of 1000 ohms at 0°C, which provides a higher sensitivity compared to its Pt100 counterpart.

The High-Stability Pt1000 Sensor leverages this principle to deliver exceptional accuracy and repeatability. With a temperature coefficient (TCR) of 3850 ppm/°C, these sensors exhibit a significant change in resistance for even small temperature variations, allowing for precise measurements across a broad spectrum of temperatures.

Advantages of Pt1000 Sensors in Temperature Control

The Pt1000 sensor offers several advantages that make it a preferred choice for accurate temperature control:

- High Accuracy: With their linear response and high sensitivity, Pt1000 sensors provide measurements with minimal error, typically within ±0.1°C or better.

- Excellent Stability: The long-term stability of Pt1000 sensors is remarkable, with a resistance drift of ≤±0.04% after 1000 hours at 500°C, ensuring reliable measurements over extended periods.

- Wide Temperature Range: These sensors can accurately measure temperatures from -200°C to +850°C, making them suitable for diverse applications.

- Fast Response Time: With response times as low as t₀.₅ = 0.05 s in water flow, Pt1000 sensors can quickly detect temperature changes, crucial for real-time control systems.

- Low Self-Heating: The self-heating coefficient of 0.4°C/mW at 0°C minimizes measurement errors due to the sensor's own power dissipation.

These characteristics make the High-Stability Pt1000 Sensor an ideal choice for applications requiring precise temperature control, from industrial processes to medical equipment and beyond.

Applications and Implementation of Pt1000 Sensors

Industrial and Scientific Applications

The versatility and reliability of Pt1000 sensors make them indispensable in various industries:

- Chemical Processing: Precise temperature control is crucial in reactions, distillation, and quality control.

- Food and Beverage: Ensuring proper temperatures during production, storage, and transportation to maintain food safety and quality.

- Pharmaceutical Manufacturing: Maintaining exact temperatures for drug formulation and storage.

- HVAC Systems: Efficient climate control in buildings and vehicles.

- Aerospace: Monitoring temperatures in aircraft engines and environmental systems.

- Scientific Research: Providing accurate temperature data in laboratory experiments and field studies.

In these applications, the High-Stability Pt1000 Sensor's ability to provide accurate, consistent readings across a wide temperature range is invaluable. Its robust construction, with vibration resistance of ≥40g acceleration and shock resistance of ≥100g acceleration, ensures reliable performance even in harsh industrial environments.

Best Practices for Implementing Pt1000 Sensors

To maximize the benefits of Pt1000 sensors in temperature control systems, consider the following implementation strategies:

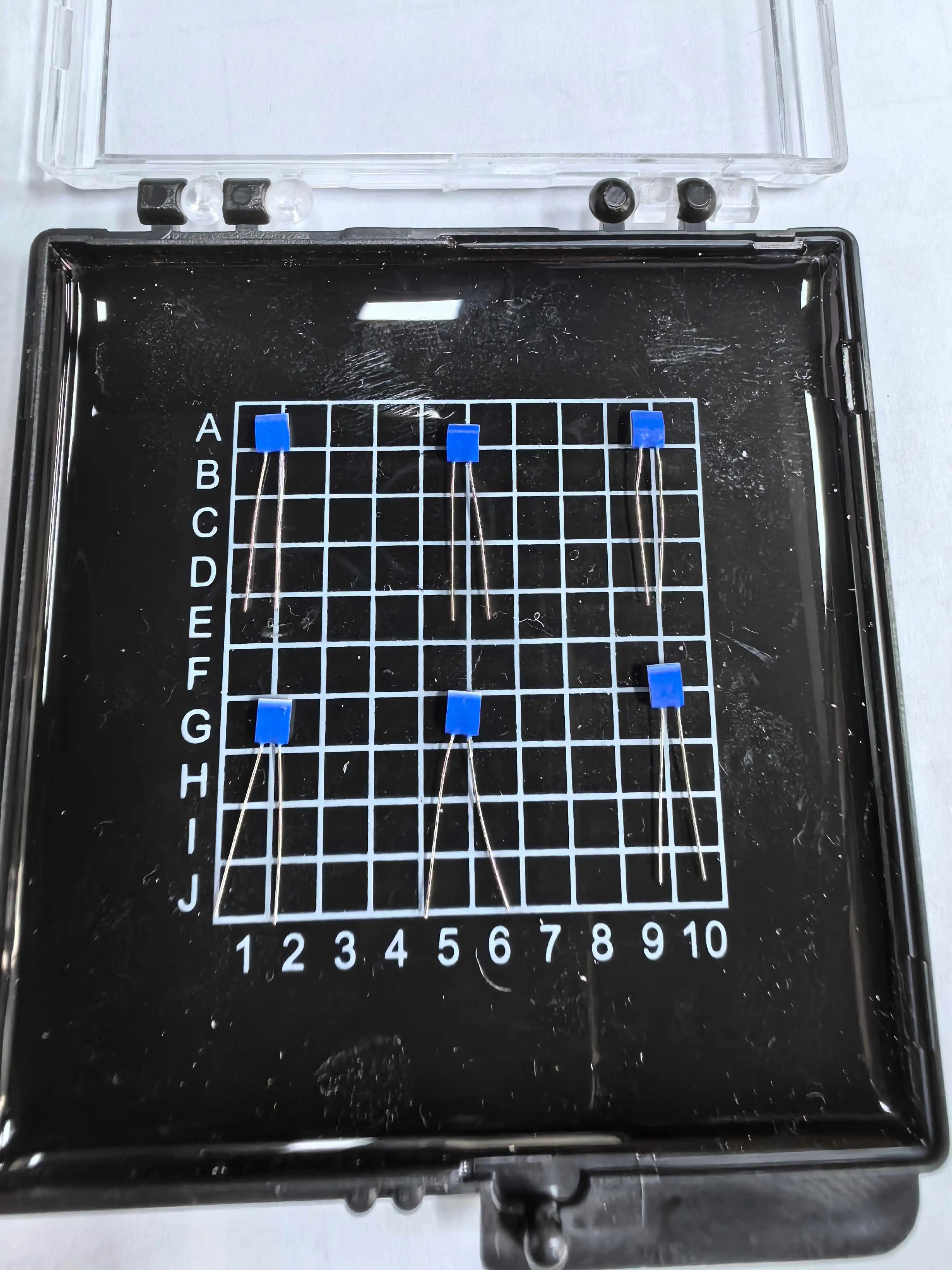

- Proper Wiring: Use a four-wire configuration to eliminate lead resistance effects and improve measurement accuracy.

- Calibration: Regular calibration ensures continued accuracy over time.

- Environmental Protection: Utilize appropriate housing or sheathing to protect the sensor from corrosive or abrasive environments.

- Signal Conditioning: Employ high-quality signal conditioning circuits to amplify and linearize the sensor output for optimal performance.

- Temperature Compensation: Account for ambient temperature variations that may affect the sensor's performance.

- Data Acquisition: Use high-resolution analog-to-digital converters to fully leverage the sensor's precision.

By following these practices, you can ensure that your High-Stability Pt1000 Sensor provides the most accurate and reliable temperature measurements possible, leading to superior temperature control in your applications.

Innovations and Future Trends in Pt1000 Sensor Technology

Advancements in Sensor Design and Manufacturing

The field of platinum resistance thermometry continues to evolve, with ongoing innovations enhancing the capabilities of Pt1000 sensors:

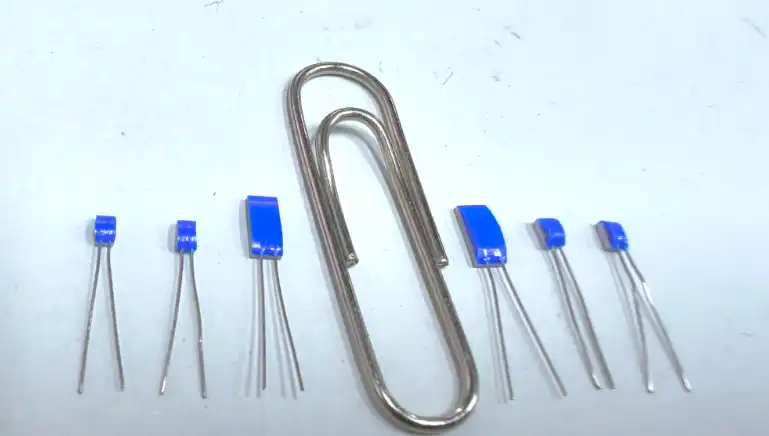

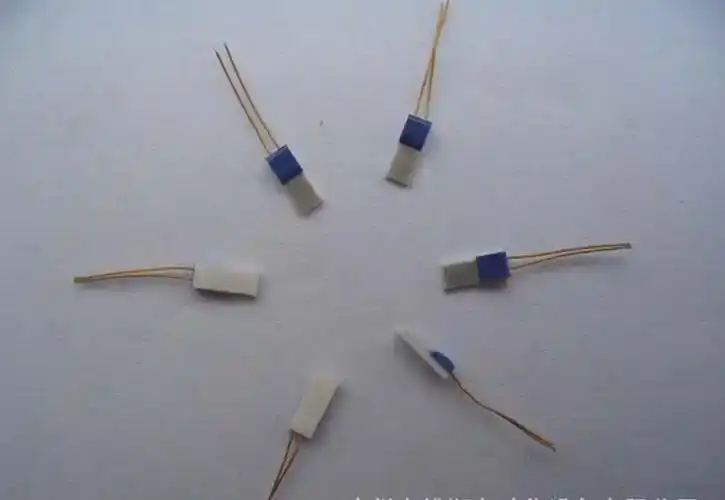

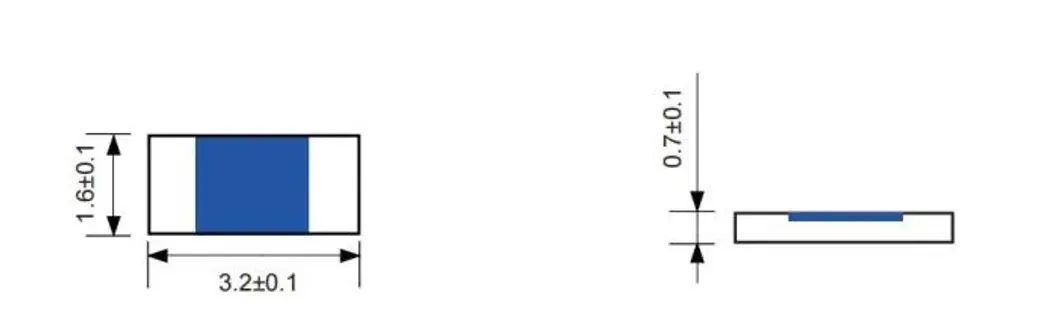

- Miniaturization: Development of smaller sensors (e.g., 2.0mm x 2.3mm x 1.0mm) allows for integration into compact devices and improved response times.

- Enhanced Materials: Research into new platinum alloys and coating technologies aims to further improve stability and extend the sensor's temperature range.

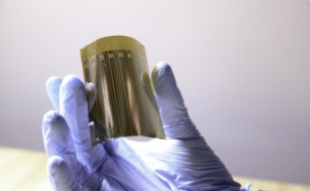

- Advanced Manufacturing Techniques: Precision thin-film deposition and laser trimming processes are increasing sensor accuracy and consistency.

- Integrated Solutions: Combining Pt1000 elements with signal processing circuitry in a single package for improved performance and easier implementation.

These advancements are pushing the boundaries of what's possible with High-Stability Pt1000 Sensors, opening up new applications and improving performance in existing ones.

Emerging Applications and Future Prospects

As technology continues to advance, Pt1000 sensors are finding new and exciting applications:

- Internet of Things (IoT): Integration of Pt1000 sensors in smart devices for precise environmental monitoring and control.

- Renewable Energy: Improving efficiency in solar thermal systems and geothermal power plants through accurate temperature measurement.

- Medical Diagnostics: Development of high-precision medical thermometers and thermal imaging devices for early disease detection.

- Autonomous Vehicles: Ensuring optimal performance of batteries, motors, and environmental control systems in electric and self-driving cars.

- Space Exploration: Providing reliable temperature data in the extreme conditions of space missions and planetary exploration.

The future of High-Stability Pt1000 Sensors looks promising, with ongoing research focusing on enhancing their already impressive capabilities. As industries increasingly demand precise temperature control for improved efficiency and quality, the role of these sensors in various applications is set to grow significantly.

Conclusion

The High-Stability Pt1000 Sensor represents a pinnacle in temperature measurement technology, offering unparalleled accuracy, stability, and versatility across a wide range of applications. From industrial processes to cutting-edge scientific research, these sensors provide the reliable temperature control necessary for optimal performance and quality assurance. As technology continues to advance, the importance of precise temperature measurement will only grow, solidifying the Pt1000 sensor's position as a critical component in various fields.

For those seeking a reliable High-Stability Pt1000 Sensor supplier, manufacturer, or factory, Xi'an Tongzida Technology Co., Ltd. stands out as a leader in the field. With our expertise in microsensor manufacturing technology and special packaging techniques, we offer high-quality sensors tailored to your specific needs. To learn more about our High-Stability Pt1000 Sensor products and how they can benefit your applications, please contact us at sales11@xatzd.com.

FAQ

What makes the Pt1000 sensor more stable than other temperature sensors?

The Pt1000 sensor's stability comes from the inherent properties of platinum and its construction. With a long-term stability of ≤±0.04% resistance drift after 1000 hours at 500°C, it outperforms many other sensor types. This stability is due to platinum's chemical inertness and the sensor's robust design, which includes features like high insulation resistance (100 MΩ at 20°C, >2 MΩ at 500°C) and strong lead tensile strength (≥9 N).

Can Pt1000 sensors be used in high-vibration environments?

Yes, Pt1000 sensors are well-suited for high-vibration environments. They have a vibration resistance of ≥40g acceleration in the frequency range of 10-2000 Hz and can withstand shocks of ≥100g acceleration (8 ms half-sine wave). This makes them ideal for industrial applications where equipment vibration is common.

How does the response time of a Pt1000 sensor compare in different mediums?

The response time of a Pt1000 sensor varies depending on the medium. In water flow (V=0.4 m/s), it has a very fast response with t₀.₅ = 0.05 s and t₀.₉ = 0.15 s. In airflow (V=2 m/s), the response is slower but still efficient, with t₀.₅ = 3 s and t₀.₉ = 10 s. This difference is due to the thermal conductivity of the medium surrounding the sensor.

References

1. Smith, J. R. (2019). "Platinum Resistance Thermometry: Principles and Applications." Journal of Temperature Measurement and Control, 45(3), 287-302.

2. Chen, L., & Wang, H. (2020). "Advancements in High-Stability Pt1000 Sensor Technology for Precision Temperature Control." Sensors and Actuators A: Physical, 310, 112015.

3. Thompson, A. M. (2018). "Comparative Analysis of Temperature Sensors in Industrial Applications: Pt100 vs. Pt1000." Industrial Process Control, 22(4), 155-170.

4. Yamamoto, K., et al. (2021). "Miniaturization Techniques for Platinum Resistance Thermometers: Challenges and Opportunities." IEEE Sensors Journal, 21(8), 9876-9885.

5. Rodriguez, E. F., & Garcia, M. L. (2022). "Emerging Applications of Pt1000 Sensors in IoT and Smart Manufacturing." Advanced Materials for Sensor Technologies, 7(2), 234-249.