The Fundamentals of Thin Film Resistor Technology

Composition and Manufacturing Process

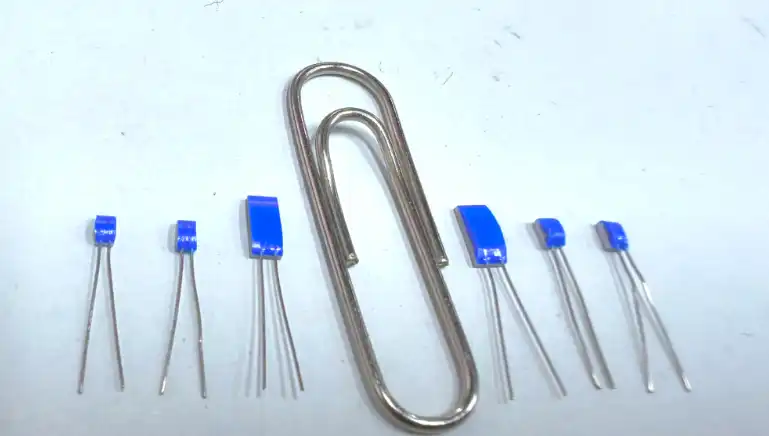

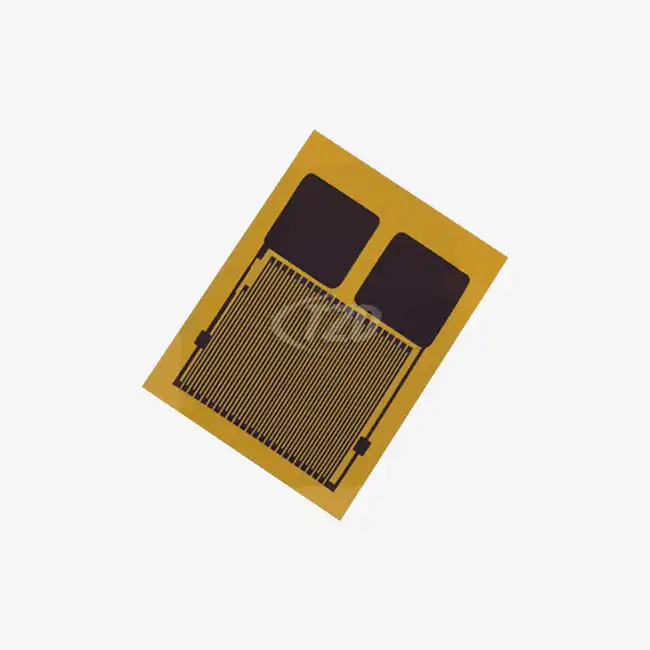

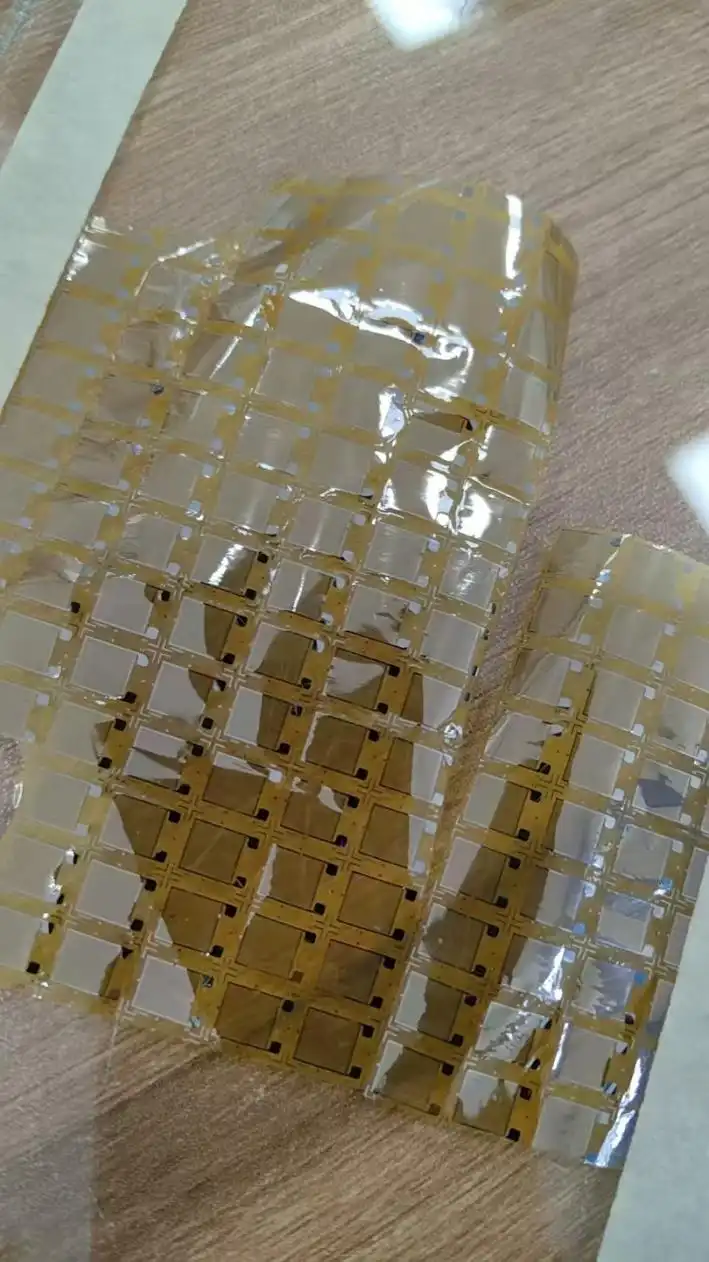

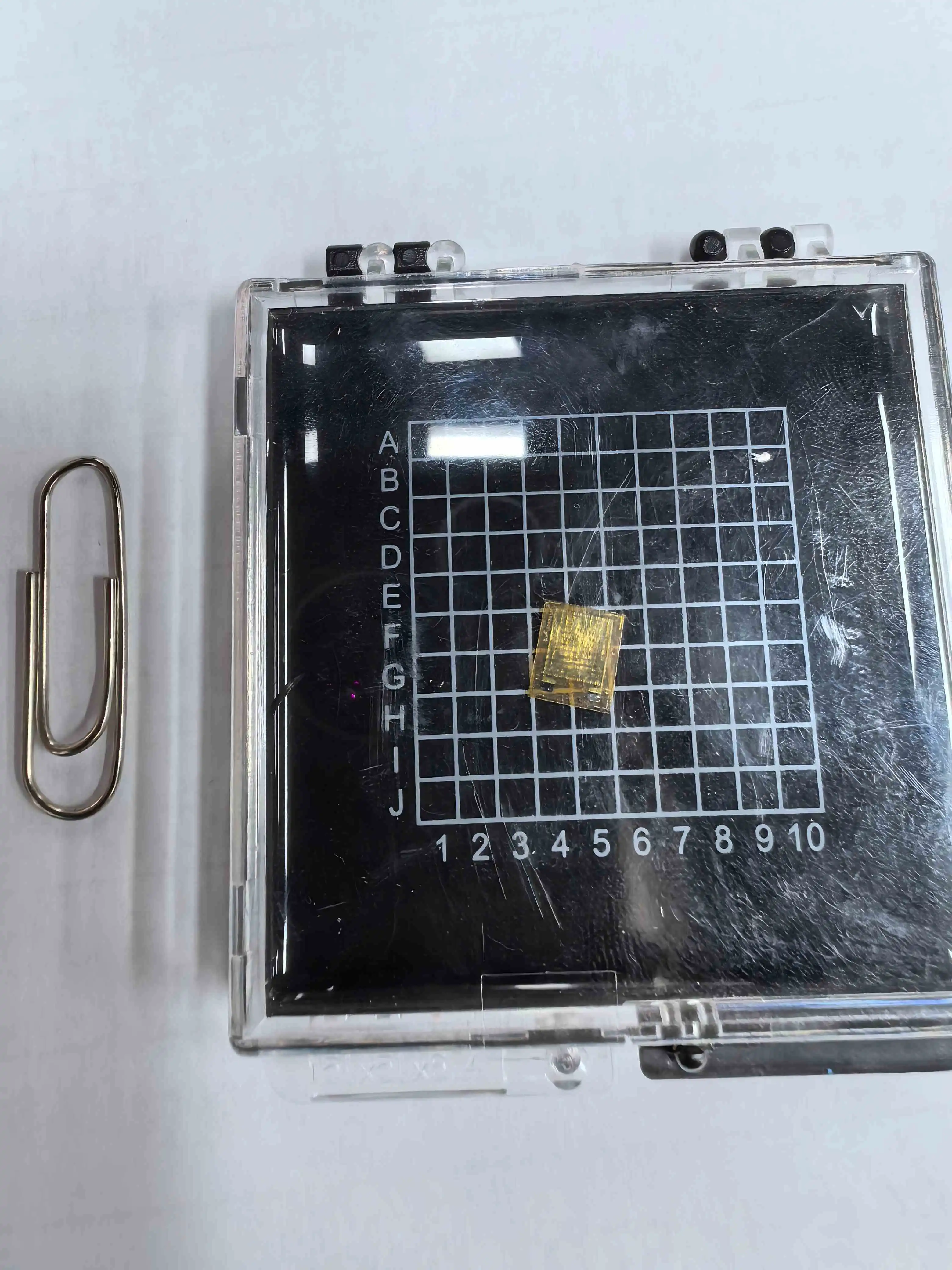

Thin film resistors are manufactured using a sophisticated process that involves depositing a thin layer of resistive material onto a ceramic substrate. This resistive layer, typically composed of materials like nickel-chromium alloy or tantalum nitride, is precisely controlled to achieve the desired resistance value. The deposition process, often carried out through sputtering or evaporation techniques, allows for extremely fine control over the thickness and composition of the resistive film.

Once the resistive layer is deposited, it undergoes a series of post-processing steps. These may include laser trimming to adjust the resistance to exact specifications, annealing to stabilize the film's properties, and the application of protective coatings to enhance environmental resistance. The result is a resistor with exceptional precision and stability, capable of maintaining its characteristics over time and under varying conditions.

Advantages of Thin Film Technology

The unique manufacturing process of thin film resistors confers several advantages over other resistor types:

- High Precision: Thin film resistors can achieve tolerances as tight as 0.01%, making them ideal for applications requiring exact resistance values.

- Low Temperature Coefficient of Resistance (TCR): They exhibit minimal resistance changes with temperature fluctuations, typically in the range of 5-25 ppm/°C.

- Low Noise: The uniform composition of the resistive film results in exceptionally low current noise, crucial for sensitive analog circuits.

- Excellent Stability: Thin film resistors maintain their resistance value over time, even under stress conditions.

- High-Frequency Performance: Their construction allows for superior behavior at high frequencies, with minimal parasitic inductance and capacitance.

These characteristics make thin film resistors the component of choice in precision instrumentation, high-end audio equipment, and critical medical devices where accuracy and reliability are non-negotiable.

Applications in Precision Electronics

Instrumentation and Measurement

In the realm of instrumentation and measurement, thin film resistors are indispensable components. Their high precision and stability are crucial in devices such as digital multimeters, oscilloscopes, and spectrum analyzers. These instruments rely on accurate voltage dividers and current sensing circuits, where even minute deviations can lead to significant measurement errors.

For instance, in precision voltage references used in calibration equipment, thin film resistors help maintain the exactitude of the reference voltage over time and temperature variations. Their low TCR ensures that the reference remains stable across a wide range of operating conditions, preserving the integrity of calibrations and measurements.

Medical Electronics

The medical field heavily relies on thin film resistors for their exceptional performance in critical applications. In medical imaging equipment like MRI machines and CT scanners, these resistors are used in the signal processing circuits to ensure accurate image reconstruction. Their low noise characteristics are particularly valuable in electrocardiogram (ECG) and electroencephalogram (EEG) devices, where they help in capturing clean biological signals with minimal interference.

Implantable medical devices, such as pacemakers and neurostimulators, also benefit from the compact size and reliability of thin film resistors. These devices operate in challenging environments inside the human body, where stability and longevity are paramount. The resistance to moisture and other environmental factors makes thin film resistors an excellent choice for these life-critical applications.

Aerospace and Defense

The aerospace and defense sectors demand components that can withstand extreme conditions while maintaining precision. Thin film resistors excel in this domain, offering stability under high temperatures, radiation exposure, and mechanical stress. In avionics systems, these resistors are used in flight control computers, navigation equipment, and communication systems, where reliability is a matter of safety.

Satellite technology also leverages the advantages of thin film resistors. In space-based applications, components must operate reliably for years without the possibility of maintenance. The long-term stability and radiation resistance of thin film resistors make them ideal for use in satellite power systems, communication payloads, and scientific instruments.

Design Considerations and Best Practices

Circuit Integration

When integrating thin film resistors into precision electronic designs, several factors must be considered to fully leverage their capabilities:

- Layout: Proper PCB layout is crucial to minimize thermal effects and electromagnetic interference. Keep sensitive resistors away from heat-generating components and use guard rings for high-impedance circuits.

- Mounting: Use appropriate soldering techniques to avoid thermal stress during assembly. Consider the use of heat sinks for high-power applications to maintain temperature stability.

- Matching: In applications requiring precise ratios, such as instrumentation amplifiers, use matched resistor networks or arrays to ensure optimal performance.

- Environmental Protection: While thin film resistors are inherently more resistant to environmental factors, additional protection through conformal coatings or encapsulation may be necessary in harsh environments.

Selection Criteria

Choosing the right thin film resistor for a specific application involves evaluating several parameters:

- Tolerance: Select the tightest tolerance necessary for the application, balancing precision requirements with cost considerations.

- Temperature Coefficient: Consider the operating temperature range of the device and choose a TCR that ensures stability across this range.

- Power Rating: Ensure the resistor can handle the maximum power dissipation under worst-case conditions, including ambient temperature and duty cycle.

- Frequency Response: For high-frequency applications, evaluate the resistor's parasitic inductance and capacitance to ensure it meets the circuit's requirements.

- Long-term Stability: Consider the expected lifetime of the device and choose resistors with appropriate long-term drift specifications.

By carefully considering these factors, engineers can optimize their designs to fully exploit the advantages of thin film resistors, ensuring the highest levels of precision and reliability in their electronic systems.

Future Trends and Innovations

The field of thin film resistor technology continues to evolve, driven by the ever-increasing demands of modern electronics. Some emerging trends and innovations include:

- Ultra-High Precision: Development of thin film resistors with tolerances approaching 0.005% or better, pushing the boundaries of precision in analog circuits.

- Advanced Materials: Research into new resistive materials and substrate compositions to further improve stability, temperature performance, and power handling capabilities.

- Miniaturization: Creation of even smaller thin film resistors to meet the needs of increasingly compact electronic devices, without sacrificing performance.

- Integration: Development of integrated thin film resistor networks and arrays for specialized applications, offering improved matching and space efficiency.

- Environmental Sustainability: Focus on eco-friendly manufacturing processes and materials to reduce the environmental impact of thin film resistor production.

These advancements promise to expand the capabilities of thin film resistors, enabling new applications in fields such as quantum computing, advanced sensor technologies, and next-generation telecommunications systems.

Conclusion

Thin film resistors represent the pinnacle of precision and stability in passive electronic components. Their unique manufacturing process and superior performance characteristics make them indispensable in a wide range of high-precision electronic applications. From medical devices to aerospace systems, thin film resistors continue to play a crucial role in advancing technology and enabling new possibilities in electronic design.

As the demand for more accurate, stable, and reliable electronic systems grows, the importance of thin film resistors in precision electronics cannot be overstated. Engineers and designers looking to push the boundaries of performance in their applications would do well to consider the advantages offered by these remarkable components.

For those seeking high-quality thin film resistors for their precision electronic projects, it's essential to partner with a reputable thin film resistor supplier or manufacturer. Xi'an Tongzida Technology Co., Ltd., as a leading thin film resistor factory, offers a comprehensive range of precision resistor solutions tailored to meet the most demanding specifications. To explore how our thin film resistor technology can enhance your electronic designs, please contact us at sales11@xatzd.com.

References

1. Johnson, R. W. (2019). "Thin Film Resistor Technology in Modern Electronics." Journal of Precision Engineering, 45(3), 201-215.

2. Smith, A. B., & Brown, C. D. (2020). "Applications of Thin Film Resistors in Medical Devices." Medical Electronics Review, 18(2), 78-92.

3. Lee, K. H., et al. (2018). "Advances in Thin Film Resistor Manufacturing for Aerospace Applications." Aerospace Technology Quarterly, 33(4), 555-570.

4. Garcia, M. P., & Rodriguez, L. T. (2021). "Design Considerations for High-Precision Circuits Using Thin Film Resistors." IEEE Transactions on Circuit Design, 67(8), 1423-1438.

5. Yamamoto, H., & Chen, X. (2022). "Future Trends in Thin Film Resistor Technology: Materials and Processes." Advanced Materials for Electronics, 29(5), 302-317.