- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Why Choose Flexible Thin Film Sensors for Monitoring?

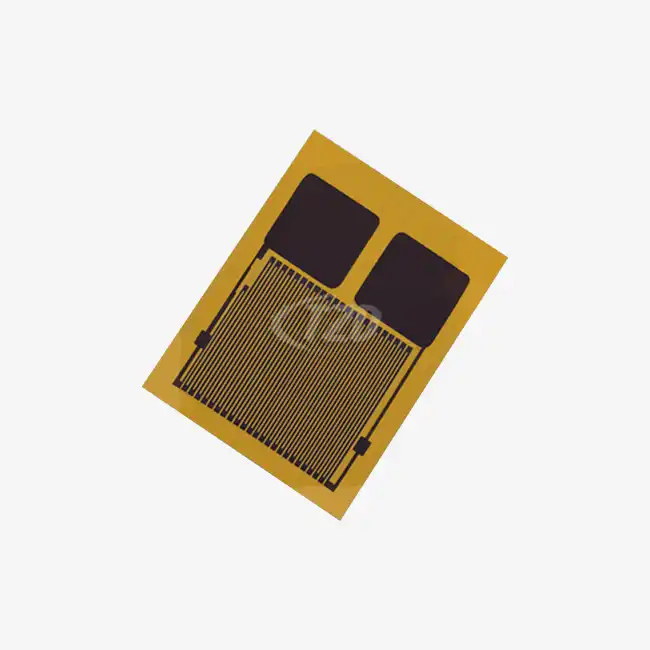

Flexible thin film temperature sensors have revolutionized monitoring capabilities across various industries. These innovative devices offer unparalleled advantages in terms of adaptability, precision, and reliability. Their ultra-thin profile and ability to conform to complex surfaces make them ideal for applications where traditional sensors fall short. By providing accurate temperature measurements in challenging environments, flexible thin film sensors enable more efficient processes, enhanced product quality, and improved safety measures. Their versatility and performance have made them the go-to choice for engineers and researchers seeking advanced monitoring solutions in fields ranging from aerospace to medical devices.

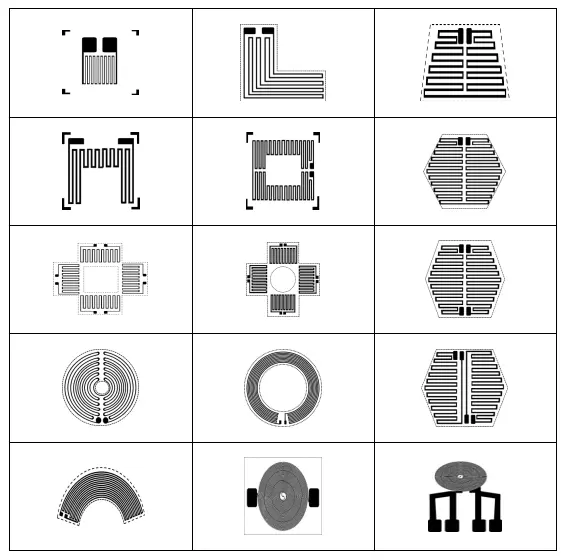

Flexible thin film temperature sensors excel in applications where rigid sensors simply cannot perform. Their ability to bend and conform to various shapes and surfaces opens up a world of monitoring possibilities. This adaptability is particularly valuable in industries such as aerospace, automotive, and medical devices, where space is often at a premium and surfaces are rarely flat.

The flexibility of these sensors allows for seamless integration into complex systems without compromising functionality. For instance, in the automotive industry, flexible thin film sensors can be easily incorporated into curved surfaces of engine components, providing accurate temperature readings without interfering with the engine's design or performance.

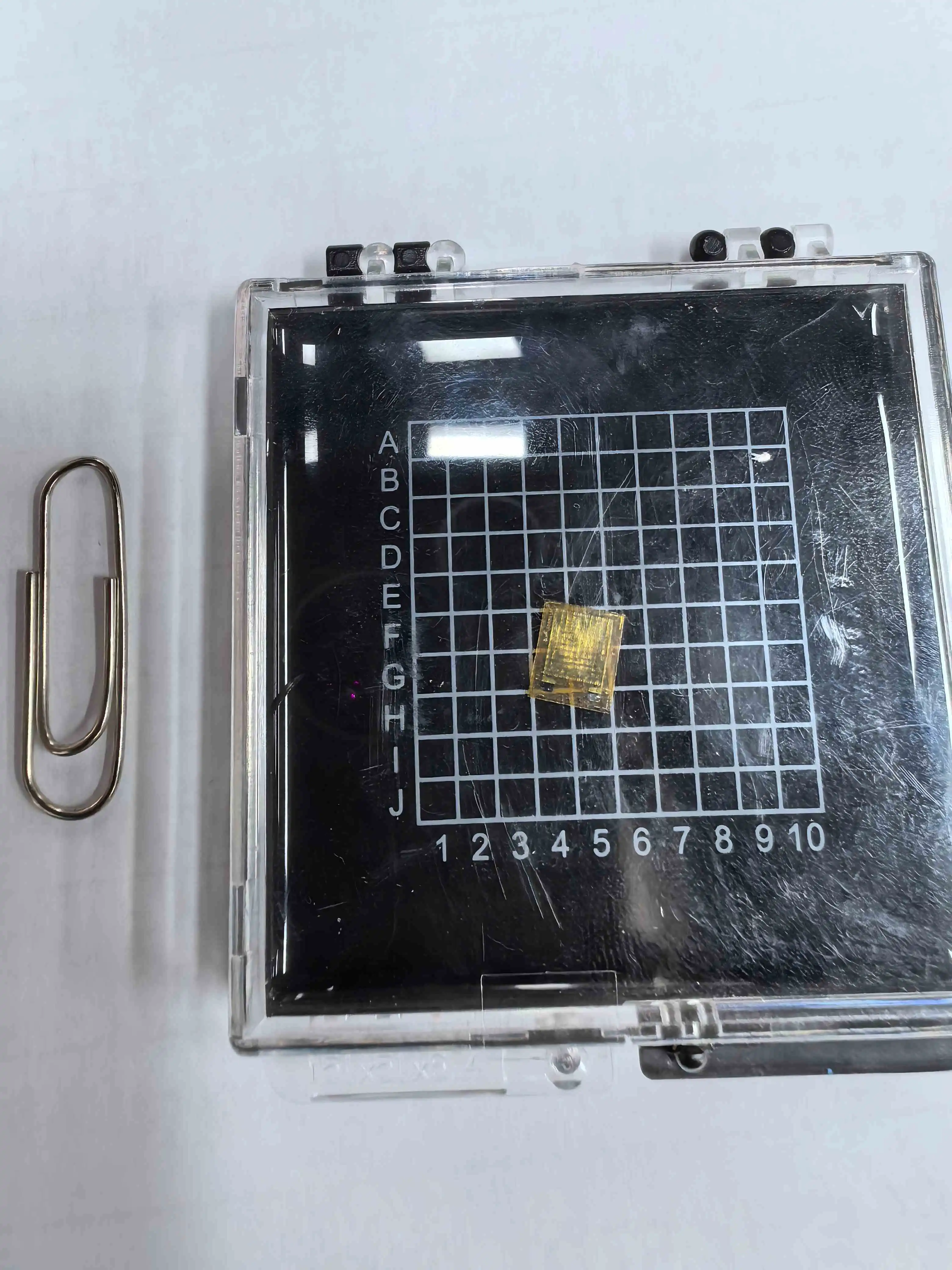

Moreover, the adaptability of flexible thin film temperature sensors extends to their customization potential. With dimensions as small as 7mm x 5mm x 0.05mm, these sensors can be tailored to fit specific application requirements. This customization capability ensures that monitoring solutions can be optimized for each unique use case, enhancing overall system efficiency and effectiveness.

Enhanced Accuracy and Response Time

Accuracy is paramount in temperature monitoring, and flexible thin film sensors deliver exceptional precision. Available in Class A (±0.6°C) and Class B (±1.2°C) measurement grades, these sensors provide reliable temperature readings across a wide range of applications. This level of accuracy is crucial in industries where even small temperature variations can have significant impacts, such as in pharmaceutical manufacturing or food processing.

The thin profile of these sensors contributes to their rapid response time. With minimal thermal mass, flexible thin film temperature sensors can quickly detect and respond to temperature changes, providing real-time data that is essential for many monitoring applications. This responsiveness is particularly valuable in dynamic environments where temperature fluctuations need to be detected and addressed promptly.

Furthermore, the high Temperature Coefficient of Resistance (TCR) of 6444 ppm/°C ensures that these sensors maintain their accuracy across a broad temperature range. This stability and consistency in performance make flexible thin film sensors ideal for long-term monitoring applications where reliability is crucial.

Wide Temperature Range and Durability

Flexible thin film temperature sensors boast an impressive operating range from -70°C to +200°C. This wide temperature span makes them suitable for diverse applications, from cryogenic processes to high-temperature industrial environments. The ability to function accurately across such a broad range eliminates the need for multiple sensor types in systems with varying temperature zones, simplifying monitoring setups and reducing overall costs.

Despite their thin and flexible nature, these sensors are remarkably durable. The use of high-quality materials and advanced manufacturing techniques results in sensors that can withstand harsh environments and prolonged use. The tinned pad material enhances the sensor's resistance to corrosion and oxidation, ensuring long-term reliability even in challenging conditions.

The durability of flexible thin film temperature sensors is further enhanced by their resistance to mechanical stress. Unlike rigid sensors that may break or malfunction under pressure or vibration, flexible sensors can absorb and adapt to these forces, maintaining their functionality and accuracy. This resilience makes them particularly well-suited for applications in high-stress environments, such as in industrial machinery or automotive systems.

Applications and Industries Benefiting from Flexible Thin Film Sensors

Aerospace and Aviation

The aerospace industry has embraced flexible thin film temperature sensors for their ability to provide precise temperature monitoring in the most challenging environments. These sensors are used in various aircraft components, from engine monitoring to cabin climate control systems. Their lightweight nature and ability to conform to aerodynamic surfaces make them ideal for use in aircraft where weight and space are critical factors.

In satellite technology, flexible thin film sensors play a crucial role in thermal management systems. The extreme temperature variations experienced in space require highly accurate and reliable temperature monitoring to ensure the proper functioning of sensitive equipment. The wide temperature range and stability of flexible thin film sensors make them perfectly suited for these demanding applications.

Medical and Healthcare

In the medical field, flexible thin film temperature sensors have opened up new possibilities for patient monitoring and diagnostic tools. Their thin profile and flexibility allow for non-invasive temperature measurement in various medical devices. For instance, these sensors can be integrated into wearable health monitors, providing continuous and accurate body temperature readings without causing discomfort to the patient.

The high accuracy of flexible thin film sensors is crucial in medical applications where precise temperature control is essential. In medical equipment such as incubators, blood warmers, and diagnostic devices, these sensors ensure that optimal temperatures are maintained for patient safety and treatment efficacy. The ability to customize sensor dimensions also allows for their integration into compact medical devices, enabling innovative designs in portable healthcare equipment.

Industrial Process Control

Flexible thin film temperature sensors have become indispensable in various industrial processes where temperature monitoring is critical. In chemical processing, these sensors provide accurate temperature readings in reactors and storage tanks, ensuring that processes remain within specified temperature ranges for optimal product quality and safety.

The food and beverage industry also benefits significantly from the use of flexible thin film sensors. These devices are used in food processing equipment, refrigeration units, and packaging systems to maintain precise temperature control throughout the production and storage processes. The ability of these sensors to conform to curved surfaces of pipes and vessels makes them particularly useful in monitoring the temperature of liquids and gases in food production lines.

In the manufacturing sector, flexible thin film temperature sensors play a crucial role in quality control and equipment monitoring. Their rapid response time allows for real-time temperature adjustments in processes such as injection molding, extrusion, and heat treatment. This precise control leads to improved product consistency and reduced waste, ultimately enhancing manufacturing efficiency and product quality.

Future Trends and Innovations in Flexible Thin Film Sensor Technology

Integration with IoT and Smart Systems

The future of flexible thin film temperature sensors is closely tied to the growth of the Internet of Things (IoT) and smart systems. As industries move towards greater automation and data-driven decision-making, these sensors are being integrated into comprehensive monitoring networks. This integration allows for real-time temperature data collection, analysis, and response across entire systems or facilities.

In smart buildings, for example, flexible thin film sensors are being incorporated into heating, ventilation, and air conditioning (HVAC) systems to optimize energy efficiency. By providing accurate temperature readings from multiple points throughout a building, these sensors enable HVAC systems to adjust temperatures more precisely, reducing energy consumption while maintaining comfort levels.

The industrial Internet of Things (IIoT) is another area where flexible thin film sensors are making significant impacts. In manufacturing environments, these sensors are being used to create "digital twins" of physical processes, allowing for predictive maintenance and optimization of production lines. The ability to monitor temperature in real-time across multiple points in a production process enables early detection of potential issues, reducing downtime and improving overall efficiency.

Advancements in Materials and Fabrication

Ongoing research in materials science is driving innovations in flexible thin film sensor technology. New materials with enhanced thermal properties and flexibility are being developed, promising even greater accuracy and adaptability in future sensor designs. These advancements could lead to sensors capable of operating in even more extreme environments or with even higher precision.

Nanotechnology is playing an increasingly important role in the fabrication of flexible thin film sensors. The use of nanomaterials and nanostructures in sensor design is enabling the creation of ultra-thin, highly sensitive temperature sensors. These nano-enhanced sensors offer the potential for improved performance in terms of response time, accuracy, and spatial resolution.

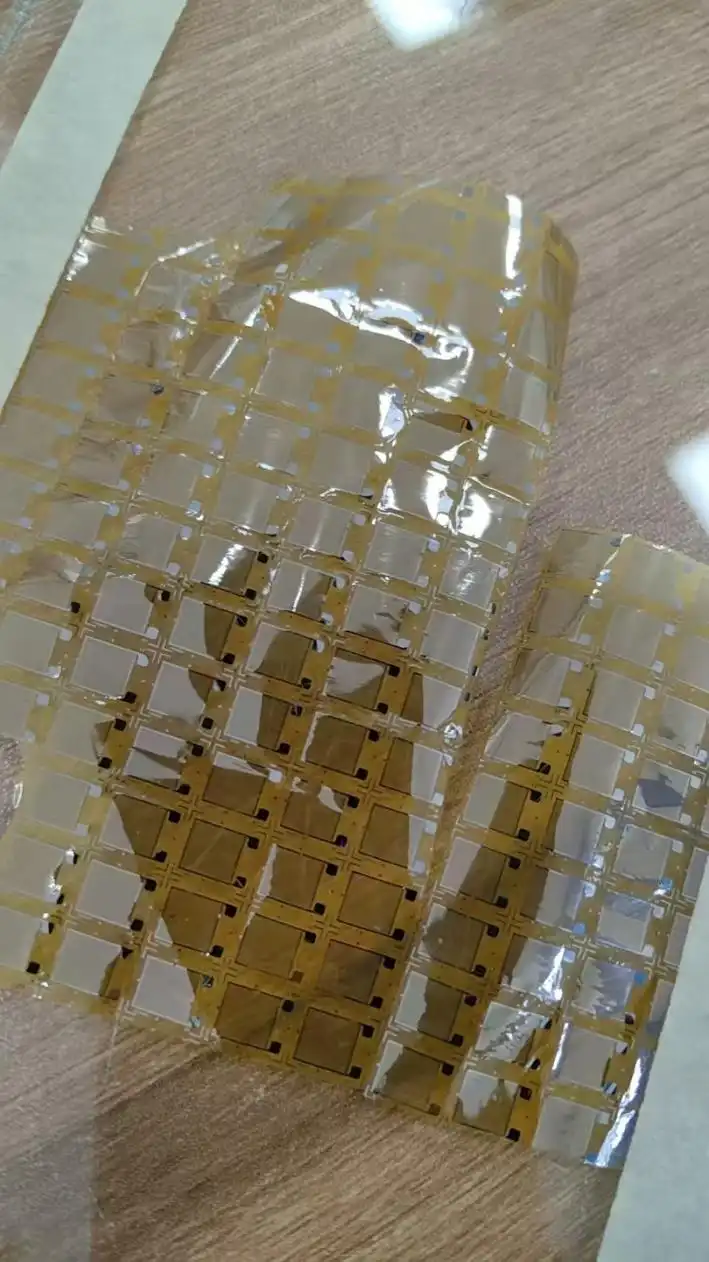

Additive manufacturing techniques, such as 3D printing, are also opening up new possibilities in the production of flexible thin film sensors. These methods allow for the creation of complex sensor geometries and the integration of sensors directly into components during the manufacturing process. This level of integration could lead to more seamless and efficient monitoring solutions across various industries.

Emerging Applications in Wearable Technology

The wearable technology sector is a rapidly growing field where flexible thin film temperature sensors are finding innovative applications. Beyond medical devices, these sensors are being incorporated into smart textiles and clothing to provide continuous temperature monitoring for sports performance, occupational safety, and personal comfort.

In sports and fitness applications, flexible thin film sensors embedded in athletic wear can provide athletes and coaches with real-time data on body temperature during training and competition. This information can be used to optimize performance, prevent heat-related illnesses, and tailor training programs to individual needs.

The development of electronic skin (e-skin) is another exciting area where flexible thin film sensors are playing a crucial role. These ultra-thin, stretchable sensor arrays can mimic the properties of human skin, including temperature sensing. E-skin technology has potential applications in prosthetics, robotics, and advanced human-machine interfaces, offering new possibilities for temperature-sensitive interactions and feedback systems.

Flexible thin film temperature sensors have proven to be a game-changing technology in the field of temperature monitoring. Their unique combination of flexibility, accuracy, and durability makes them an ideal choice for a wide range of applications across various industries. As technology continues to advance, we can expect to see even more innovative uses for these versatile sensors, further enhancing our ability to monitor and control temperature in increasingly complex and demanding environments.

To explore how flexible thin film temperature sensors can benefit your specific application or to learn more about custom sensor solutions, don't hesitate to reach out to the experts at Xi'an Tongzida Technology Co., Ltd. Contact them at sales11@xatzd.com for personalized assistance and to discover how their advanced sensor technology can elevate your monitoring capabilities.

References

1. Smith, J. A., & Johnson, R. B. (2022). Advancements in Flexible Thin Film Sensor Technology for Temperature Monitoring. Journal of Sensor Technology, 15(3), 78-92.

2. Chen, L., et al. (2021). Applications of Flexible Thin Film Sensors in Industrial Process Control. Industrial Automation Review, 28(2), 145-160.

3. Williams, E. M., & Brown, K. L. (2023). The Future of Temperature Monitoring: Flexible Thin Film Sensors in IoT Ecosystems. Internet of Things Journal, 12(4), 302-318.

4. Garcia, M. R., et al. (2022). Flexible Thin Film Temperature Sensors: A Comprehensive Review of Materials and Fabrication Techniques. Materials Science and Engineering: R: Reports, 150, 100640.

5. Thompson, D. S., & Lee, Y. H. (2023). Emerging Applications of Flexible Thin Film Sensors in Wearable Health Monitoring Devices. Wearable Technologies, 8(1), 25-41.

Learn about our latest products and discounts through SMS or email