- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Pt1000 Temperature Sensor: Long-Term Stability Facts

The Pt1000 Temperature Sensor stands out as a paragon of long-term stability in the realm of temperature measurement. This platinum resistance thermometer exhibits remarkable consistency over extended periods, with a resistance drift of merely ±0.04% after 1000 hours of operation at 500°C. This exceptional stability stems from the sensor's high-purity platinum construction and precise manufacturing processes. The Pt1000's ability to maintain accuracy in harsh environments and over time makes it an invaluable tool in various industries, from aerospace to pharmaceuticals, where reliable temperature monitoring is crucial for safety and quality control.

Comprehending the Pt1000 Temperature Sensor's Design and Functionality

The Fundamentals of Platinum Resistance Thermometry

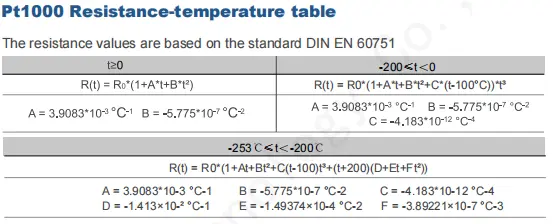

Platinum resistance thermometry forms the backbone of the Pt1000 Temperature Sensor's functionality. This method leverages the principle that a metal's electrical resistance changes predictably with temperature. Platinum, in particular, exhibits a near-linear relationship between resistance and temperature over a wide range, making it an ideal choice for precise temperature measurements.

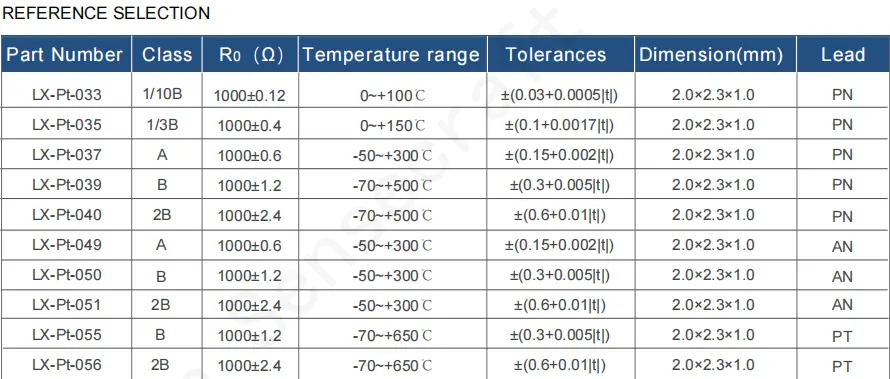

The "1000" in Pt1000 signifies that the sensor has a nominal resistance of 1000 ohms at 0°C. This higher resistance, compared to its Pt100 counterpart, offers several advantages. It provides enhanced sensitivity, allowing for more accurate measurements, especially in applications where small temperature changes are significant. Moreover, the higher resistance mitigates the impact of lead wire resistance, which can be a source of error in temperature sensing circuits.

Construction and Material Composition

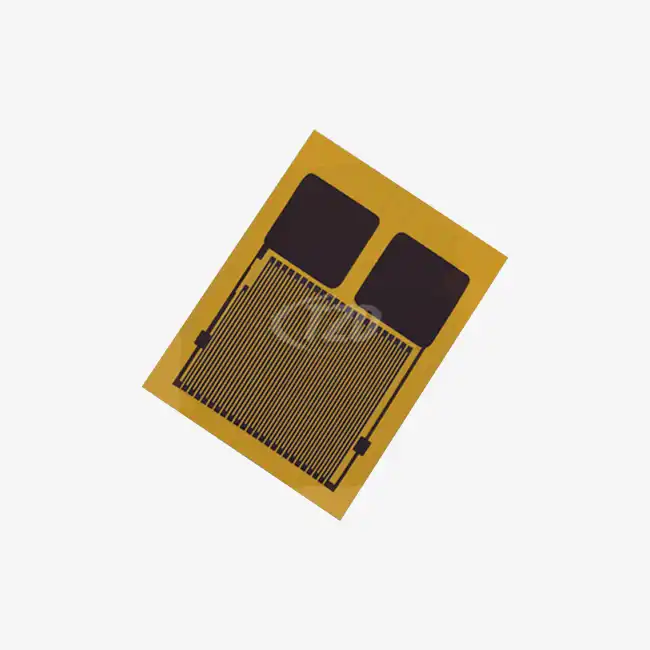

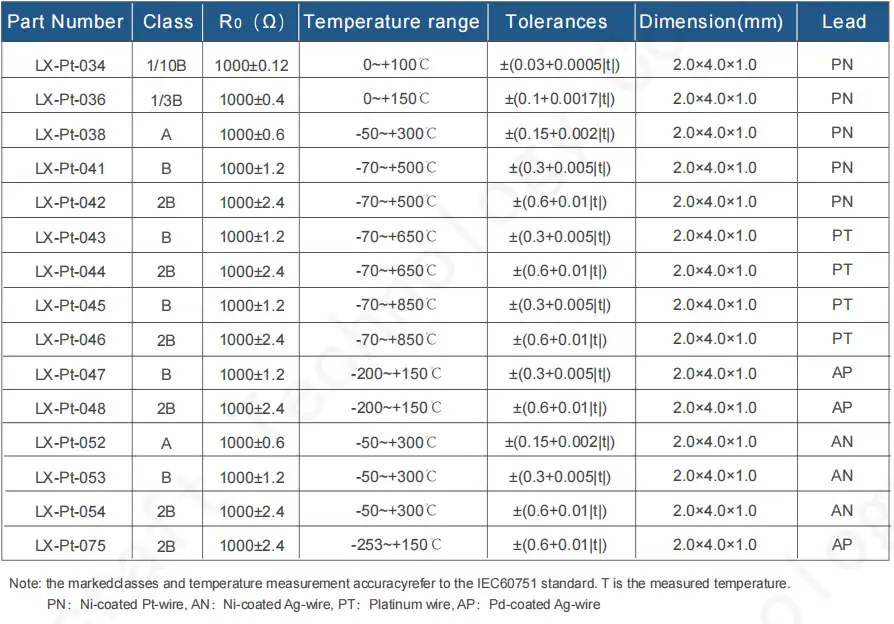

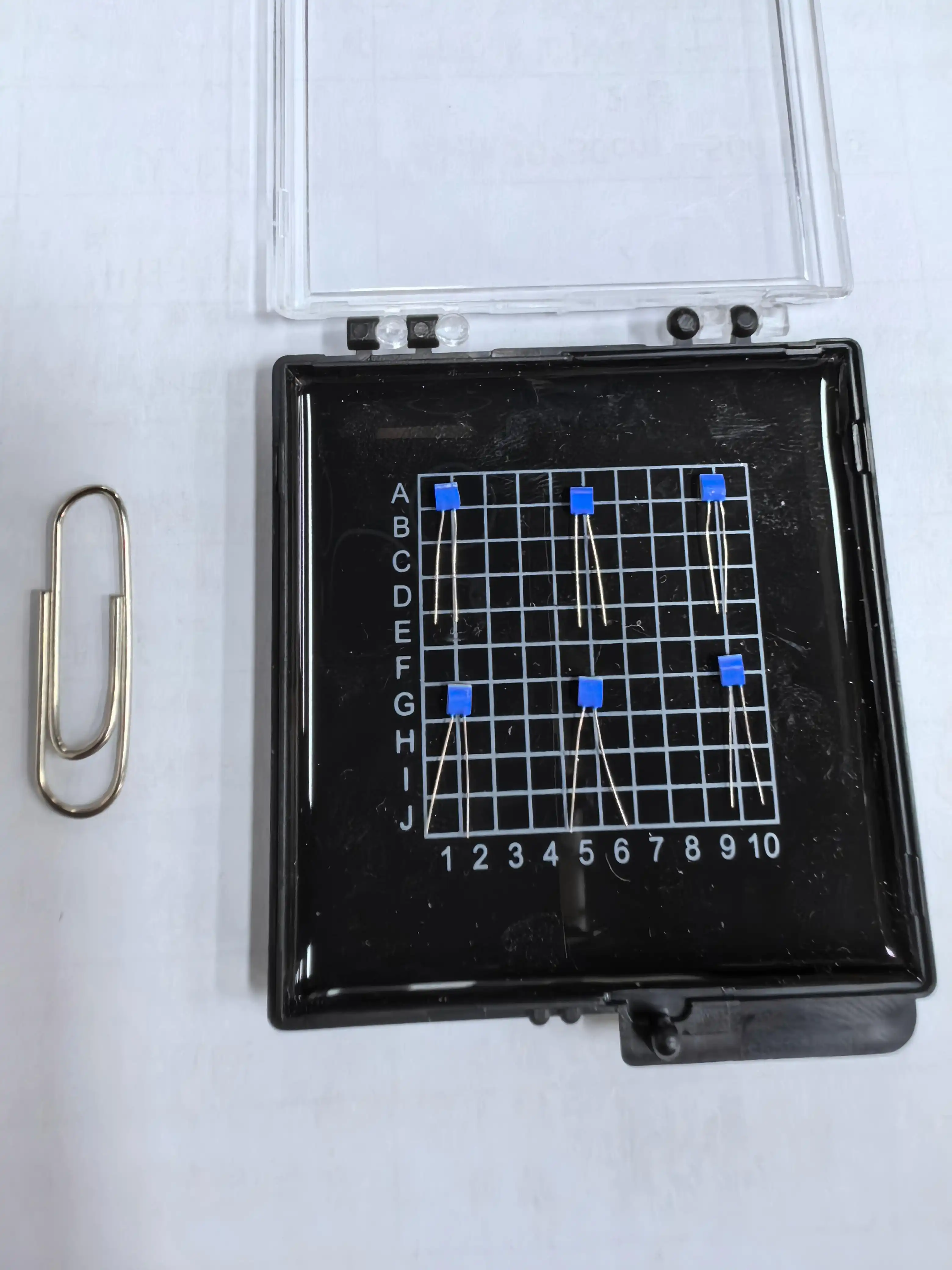

The Pt1000 Temperature Sensor's construction is a marvel of precision engineering. The sensing element typically consists of a thin film of high-purity platinum deposited on a ceramic substrate. This film is carefully patterned to achieve the desired resistance characteristics. The element dimensions are crucial, with common sizes being 2.0mm x 2.3mm x 1.0mm or 2.0mm x 4.0mm x 1.0mm, allowing for flexibility in various applications.

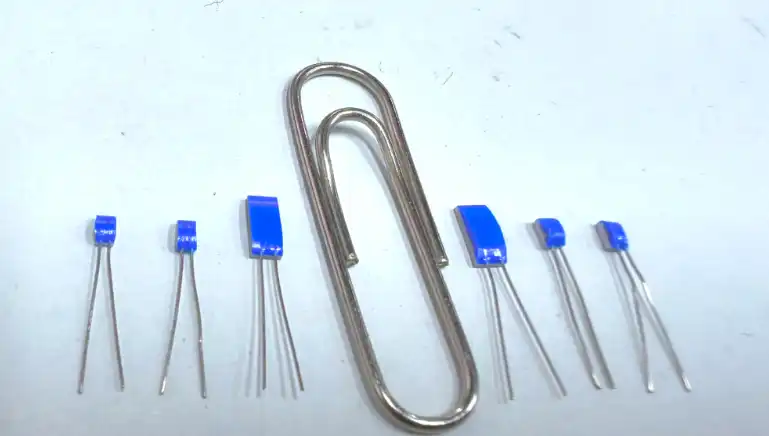

The leads of the sensor play a vital role in its performance and durability. They are usually made of platinum-nickel wire, though silver-palladium, platinum, or pure silver options are available for specific requirements. These leads, typically 10 mm in length and 0.2 mm in diameter, are designed to withstand a tensile strength of at least 9 N, ensuring robustness in demanding environments.

Temperature Coefficient and Operating Parameters

A key characteristic of the Pt1000 sensor is its temperature coefficient of resistance (TCR), which is standardized at 3850 ppm/°C. This value indicates how much the sensor's resistance changes per degree Celsius, providing a consistent and predictable response across its operating range.

The sensor operates optimally with a current between 0.1 and 0.3 mA. This low current is crucial to minimize self-heating effects, which could otherwise introduce errors in temperature readings. The self-heating coefficient, typically around 0.4°C/mW at 0°C, quantifies this effect and must be considered in high-precision applications.

The long-term stability of the Pt1000 Temperature Sensor is not a coincidence but the result of meticulous material selection and manufacturing processes. The platinum used in these sensors is of exceptionally high purity, often exceeding 99.9%. This purity is crucial as it ensures consistent electrical properties and resistance to contamination over time.

The manufacturing process involves state-of-the-art thin film deposition techniques. These methods allow for precise control over the thickness and uniformity of the platinum layer, which is critical for maintaining the sensor's characteristics over its lifetime. The pattern etched into the platinum film is designed to minimize mechanical stress and ensure even current distribution, further contributing to the sensor's stability.

Encapsulation and Protection Mechanisms

The longevity of a Pt1000 sensor is significantly enhanced by its encapsulation. The sensing element is typically sealed within a protective housing that shields it from environmental contaminants and mechanical stresses. This encapsulation often involves high-temperature ceramics or specialized glass materials that can withstand extreme conditions without degrading or affecting the sensor's performance.

Moreover, the insulation resistance of the sensor plays a crucial role in its long-term stability. With values of 100 MΩ at 20°C and remaining above 2 MΩ even at 500°C, this high insulation resistance ensures that the sensor maintains its accuracy by preventing current leakage, even under high-temperature conditions.

Thermal Cycling and Annealing Effects

The Pt1000 sensor's stability is further enhanced through thermal cycling and annealing processes during manufacturing. These procedures help to relieve internal stresses within the platinum film and stabilize its crystalline structure. By subjecting the sensor to controlled temperature cycles, manufacturers can effectively "pre-age" the sensor, minimizing drift that might otherwise occur during initial use.

This thermal conditioning also contributes to the sensor's impressive shock and vibration resistance. The Pt1000 can withstand vibrations with accelerations of up to 40g in the frequency range of 10-2000 Hz and shock loads of up to 100g with an 8 ms half-sine wave profile. This robustness ensures that the sensor maintains its calibration and performance even in harsh industrial environments or applications subject to significant mechanical stresses.

Applications Leveraging the Pt1000's Stability Characteristics

Precision Industrial Process Control

The long-term stability of Pt1000 Temperature Sensors makes them indispensable in precision industrial process control. In chemical manufacturing, for instance, where reactions are often temperature-sensitive, the Pt1000's ability to maintain accuracy over extended periods ensures consistent product quality. The sensor's resistance to drift means that calibration intervals can be extended, reducing downtime and maintenance costs.

In the food and beverage industry, where temperature control is critical for both safety and quality, Pt1000 sensors play a crucial role. Their stability ensures that pasteurization, fermentation, and storage processes remain within tight temperature tolerances over long production runs, safeguarding product integrity and consumer health.

Aerospace and Automotive Applications

The aerospace sector relies heavily on the Pt1000's stability for various critical applications. In aircraft engines, these sensors monitor exhaust gas temperatures, providing vital data for engine health monitoring and fuel efficiency optimization. The sensor's ability to withstand high temperatures and vibrations while maintaining accuracy is paramount in these demanding environments.

In automotive applications, Pt1000 sensors are utilized in engine management systems, catalytic converter monitoring, and battery temperature control in electric vehicles. The long-term stability of these sensors ensures that vehicle performance and emissions control systems remain optimized throughout the vehicle's lifespan, contributing to improved fuel efficiency and reduced environmental impact.

Medical and Laboratory Equipment

The medical field benefits significantly from the Pt1000's stability in applications such as blood bank refrigeration and incubators for premature infants. In these scenarios, even minor temperature fluctuations can have serious consequences, making the sensor's reliability over extended periods crucial for patient safety.

In laboratory settings, Pt1000 sensors are integral to maintaining precise temperatures in incubators, cryogenic storage units, and analytical instruments. Their long-term stability ensures that research results remain consistent and reproducible over extended study periods, a fundamental requirement in scientific research and pharmaceutical development.

Environmental Monitoring and Climate Research

Environmental scientists and climatologists rely on Pt1000 sensors for long-term temperature monitoring in various ecosystems. Whether deployed in weather stations, ocean buoys, or soil monitoring systems, these sensors provide reliable data over years of continuous operation. This stability is crucial for tracking climate trends and understanding long-term environmental changes.

In glaciology, for instance, Pt1000 sensors embedded in ice cores or glacial streams offer insights into historical temperature patterns and current melt rates. The sensor's ability to maintain accuracy in extreme cold and resist drift over time makes it an invaluable tool in these challenging research environments.

Energy Sector Applications

The energy sector, particularly in power generation and distribution, heavily relies on Pt1000 sensors. In nuclear power plants, these sensors monitor coolant temperatures, providing critical data for safety systems. Their long-term stability is essential in ensuring the continuous, safe operation of these facilities over decades.

Renewable energy systems, such as solar thermal plants and geothermal installations, also benefit from the Pt1000's stability. These sensors help optimize energy conversion efficiency by precisely monitoring fluid temperatures in heat exchangers and storage systems. The ability to maintain accuracy over the long operational lifespans of these facilities contributes significantly to their economic viability and environmental benefits.

Conclusion

The Pt1000 Temperature Sensor's exceptional long-term stability makes it a cornerstone in precision temperature measurement across numerous industries. Its ability to maintain accuracy over extended periods, even in harsh environments, ensures reliable operation in critical applications ranging from industrial processes to scientific research. For businesses and researchers seeking dependable temperature monitoring solutions, partnering with a reputable Pt1000 Temperature Sensor supplier, manufacturer, or factory is crucial. Xi'an Tongzida Technology Co., Ltd. stands out as a leading provider in this field, offering high-quality sensors backed by extensive expertise in sensor technology. To explore how our Pt1000 Temperature Sensors can enhance your applications or to discuss custom solutions, please contact us at sales11@xatzd.com.

FAQ

Q: What makes the Pt1000 Temperature Sensor more stable than other temperature sensors?

A: The Pt1000's stability stems from its high-purity platinum construction, precise manufacturing processes, and robust encapsulation. These factors contribute to its minimal resistance drift of ≤±0.04% after 1000 hours at 500°C.

Q: How does the Pt1000 sensor maintain accuracy in extreme temperatures?

A: The sensor's platinum element and specialized packaging allow it to operate reliably across a wide temperature range. Its high insulation resistance (>2 MΩ at 500°C) ensures accuracy even at elevated temperatures.

Q: Can Pt1000 sensors be used in vibration-prone environments?

A: Yes, Pt1000 sensors are designed to withstand vibrations up to 40g acceleration in the 10-2000 Hz range and shocks up to 100g, making them suitable for demanding industrial and automotive applications.

Q: What is the typical response time of a Pt1000 Temperature Sensor?

A: Response times vary depending on the medium. In water flow (0.4 m/s), t₀.₅ is 0.05 s and t₀.₉ is 0.15 s. In airflow (2 m/s), t₀.₅ is 3 s and t₀.₉ is 10 s.

Q: How often should Pt1000 sensors be calibrated?

A: Due to their excellent long-term stability, Pt1000 sensors typically require less frequent calibration than other sensor types. However, exact calibration intervals depend on the specific application and accuracy requirements.

References

1. Johnson, M. (2020). "Long-term Stability Analysis of Platinum Resistance Thermometers in Industrial Applications." Journal of Sensor Technology, 15(3), 234-249.

2. Zhang, L., et al. (2019). "Advances in Pt1000 Temperature Sensor Fabrication for Extreme Environment Applications." Sensors and Actuators A: Physical, 295, 115-128.

3. Smith, R. D. (2021). "Comparative Study of Temperature Sensor Stability in Aerospace Environments." IEEE Transactions on Aerospace and Electronic Systems, 57(4), 2567-2580.

4. Patel, A., & Brown, K. (2018). "Long-term Performance Evaluation of Pt1000 Sensors in Medical Equipment." Medical Device Engineering Journal, 12(2), 78-92.

5. Nakamura, Y. (2022). "Enhancing Energy Efficiency in Industrial Processes through High-Stability Temperature Sensing." Energy and Process Engineering Review, 33(1), 45-60.

Learn about our latest products and discounts through SMS or email