The Technology Behind Flexible Thermal Sensors

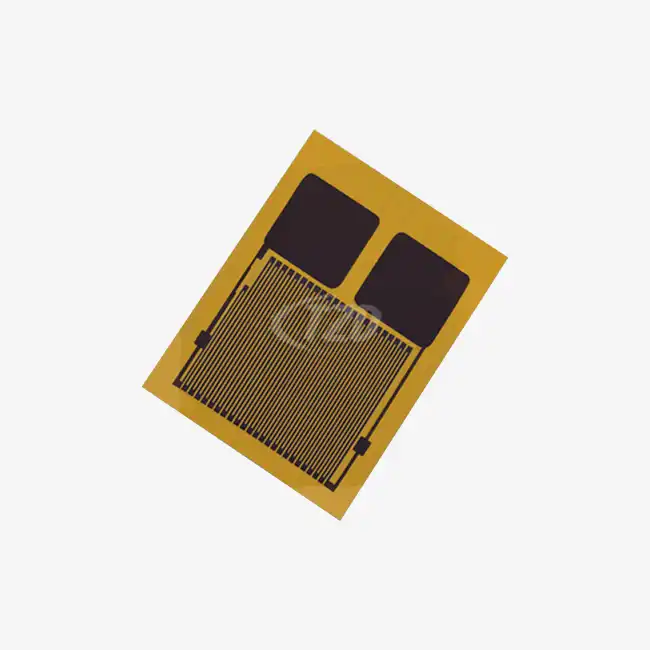

Flexible thermal sensors represent a significant advancement in temperature measurement technology. These innovative devices leverage the principles of resistive temperature detection while incorporating flexible materials and manufacturing techniques. The core of a flexible thermal sensor is typically a thin-film temperature-sensitive element, often made of platinum or other highly responsive metals.

The manufacturing process for these sensors involves depositing the temperature-sensitive material onto a flexible substrate, such as polyimide or other thermally stable polymers. This substrate provides the necessary flexibility while maintaining the sensor's integrity across a wide temperature range. Advanced microfabrication techniques, including photolithography and etching, are employed to create precise patterns of the sensing element on the substrate.

One of the key technological aspects of flexible thermal sensors is their ability to maintain accuracy despite bending and flexing. This is achieved through careful design of the sensing element's pattern and the selection of materials that can withstand repeated deformation without compromising performance. Some flexible thermal sensors also incorporate additional layers for environmental protection and electrical insulation, enhancing their durability and reliability in harsh conditions.

Temperature Measurement Capabilities

Modern flexible thermal sensors offer impressive temperature measurement capabilities. For instance, some models can operate across a temperature range of -70°C to +200°C, making them suitable for a wide array of applications. The accuracy of these sensors is often categorized into different grades, such as Class A with a tolerance of ±0.6°C or Class B with ±1.2°C, allowing users to select the appropriate level of precision for their specific needs.

The temperature coefficient of resistance (TCR) is a critical parameter in thermal sensors, indicating how the sensor's resistance changes with temperature. High-quality flexible thermal sensors can achieve a TCR of up to 6444 ppm/°C, ensuring excellent sensitivity and responsiveness to temperature variations. This high TCR value contributes to the sensor's ability to detect even subtle temperature changes quickly and accurately.

Customization and Adaptability

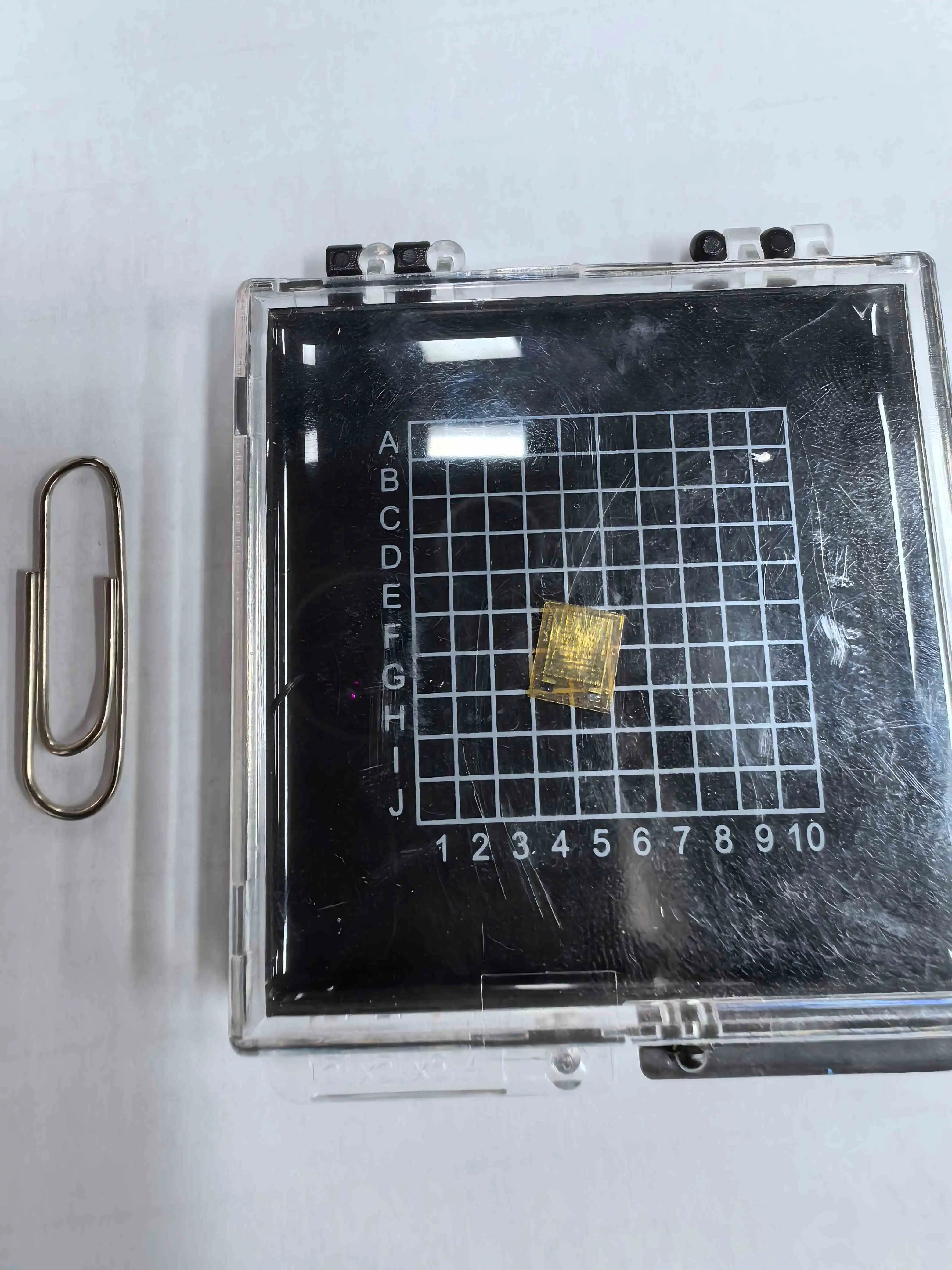

One of the most significant advantages of flexible thermal sensors is their customizability. Manufacturers can tailor these sensors to meet specific application requirements. For example, sensor dimensions can be adjusted to fit particular spaces or surfaces, with some sensors being as thin as 0.05mm while maintaining lengths and widths of several millimeters.

The adaptability of flexible thermal sensors extends to their electrical characteristics as well. Base resistance values can be specified to suit different measurement circuits and systems. Additionally, the choice of pad material, such as tinned contacts, ensures compatibility with various connection methods and environmental conditions.

Applications and Advantages of Flexible Thermal Sensors

Flexible thermal sensors have found applications across numerous industries due to their unique properties and advantages over traditional rigid sensors. Their ability to conform to non-planar surfaces makes them invaluable in scenarios where accurate temperature measurement of curved or irregular objects is crucial.

In the medical field, flexible thermal sensors are used for continuous patient monitoring, providing comfortable and accurate body temperature measurements. They can be integrated into wearable devices or medical patches, allowing for non-invasive and long-term temperature tracking.

The automotive industry utilizes these sensors for monitoring engine temperatures, battery systems in electric vehicles, and climate control systems. Their flexibility allows for easy installation in tight spaces and on curved surfaces within vehicles, providing critical thermal data for safety and performance optimization.

In aerospace applications, flexible thermal sensors play a vital role in monitoring the temperature of aircraft components, including engines, hydraulic systems, and structural elements. Their ability to withstand high vibrations and impacts (up to 40g vibration resistance and 100g impact resistance) makes them ideal for these demanding environments.

Energy Efficiency and Smart Buildings

Flexible thermal sensors are increasingly being employed in smart building technologies and energy management systems. Their thin profile and adaptability allow for seamless integration into walls, floors, and other building structures. This enables precise temperature monitoring and control, leading to improved energy efficiency and occupant comfort.

In industrial processes, these sensors offer advantages in monitoring equipment temperatures, especially in scenarios involving moving or rotating parts. Their flexibility allows for direct contact with surfaces that would be challenging for rigid sensors, resulting in more accurate and responsive temperature measurements.

Reliability and Longevity

The durability of flexible thermal sensors is a significant advantage in many applications. High-quality sensors can offer long-term stability with drift rates as low as 0.04%, ensuring reliable measurements over extended periods. This stability, combined with their resistance to mechanical stress, makes them suitable for use in environments where sensor replacement or maintenance is difficult or costly.

Furthermore, the quick response time of these sensors, some capable of reacting in as little as 0.05 seconds, allows for real-time temperature monitoring in critical applications. This rapid response can be crucial in safety systems, quality control processes, and dynamic thermal management scenarios.

Future Trends and Innovations in Flexible Thermal Sensor Technology

The field of flexible thermal sensors is rapidly evolving, with ongoing research and development pushing the boundaries of what these devices can achieve. One of the key areas of innovation is in materials science, where researchers are exploring new compounds and composites that can enhance the sensors' flexibility, temperature range, and accuracy.

Advancements in nanotechnology are leading to the development of ultra-thin and highly sensitive flexible thermal sensors. These nano-engineered sensors promise even greater conformability to complex surfaces and improved spatial resolution in temperature measurements. Such developments could revolutionize applications in fields like biomedical engineering and advanced manufacturing.

Another emerging trend is the integration of flexible thermal sensors with other types of flexible electronics. This integration is paving the way for multifunctional flexible devices that can simultaneously measure temperature, pressure, and other parameters. These integrated systems are particularly promising for wearable technology and Internet of Things (IoT) applications.

Enhanced Data Processing and Connectivity

The future of flexible thermal sensors also lies in their integration with advanced data processing capabilities. Manufacturers are developing sensors with built-in microprocessors and wireless connectivity, enabling real-time data analysis and remote monitoring. This trend aligns with the growing demand for smart, connected devices in various industries.

Machine learning and artificial intelligence are being incorporated into flexible thermal sensor systems, allowing for predictive maintenance, anomaly detection, and more sophisticated temperature control strategies. These intelligent systems can learn from historical data and adapt to changing conditions, enhancing their effectiveness in complex thermal management scenarios.

Sustainability and Environmental Considerations

As environmental concerns become increasingly important, the development of eco-friendly flexible thermal sensors is gaining traction. Researchers are exploring biodegradable materials and environmentally sustainable manufacturing processes to reduce the ecological footprint of these devices. This focus on sustainability is likely to drive innovation in both materials and production methods in the coming years.

The potential for energy harvesting in flexible thermal sensors is another area of active research. By incorporating thermoelectric materials, these sensors could potentially generate small amounts of electricity from temperature differentials, enabling self-powered operation in certain applications. This could significantly expand the use of flexible thermal sensors in remote or inaccessible locations.

Conclusion

Flexible thermal sensors represent a significant leap forward in temperature measurement technology. Their unique combination of accuracy, adaptability, and durability makes them invaluable across a wide range of industries and applications. As research continues and manufacturing techniques improve, we can expect to see even more innovative uses for these versatile devices.

The future of flexible thermal sensors is bright, with ongoing developments in materials science, data processing, and integration with other technologies promising to expand their capabilities and applications further. From enhancing energy efficiency in buildings to enabling advanced wearable medical devices, flexible thermal sensors are poised to play an increasingly important role in our technologically advanced world.

For those interested in exploring the potential of flexible thermal sensors for their specific applications or in learning more about the latest advancements in this technology, please don't hesitate to reach out to our team of experts at sales11@xatzd.com. We're committed to providing cutting-edge thermal sensing solutions tailored to your unique needs.