- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How to Choose Platinum Resistance Thermistors for Industrial Automation? A Practical Guide

How to Choose Platinum Resistance Thermistors for Industrial Automation? A Practical Guide

Selecting the right temperature sensor is critical for the success of any industrial automation system. With so many options available, how do you know which platinum resistance thermistor fits your specific automation needs? This guide walks you through the key factors to consider, ensuring you make an informed decision that enhances process efficiency and reliability.

Understand Your Industrial Automation Temperature Requirements

The first step in choosing a platinum resistance thermistor is defining your temperature range. Most industrial automation processes operate between -50°C and 500°C—a range where platinum resistance thermistors excel. If your application involves high-heat processes (e.g., metal heat treatment), ensure the thermistor has insulation resistance >2 MΩ at 500°C, as specified in our product specs.

For cold storage or low-temperature automation (e.g., food processing lines), focus on the thermistor’s accuracy at sub-zero temperatures. The 3850 ppm/°C TCR of our platinum resistance thermistors ensures consistent readings even in these conditions, avoiding the inaccuracies that can lead to product spoilage or equipment damage.

Key Specifications to Evaluate for Automation Compatibility

1. Stability and Drift

Long-term stability is non-negotiable for industrial automation, where continuous operation is the norm. Look for a platinum resistance thermistor with ≤±0.04% resistance drift after 1000 hours at 500°C. This minimizes downtime for calibration and replacement, keeping your automation line running smoothly.

2. Mechanical Durability

Automation facilities are high-vibration environments. Your platinum resistance thermistor should have vibration resistance ≥40g acceleration (10–2000 Hz) and shock resistance ≥100g acceleration. These specs ensure the sensor can withstand the mechanical stress of conveyor belts, robotic arms, and other automated equipment.

3. Response Time

Real-time temperature feedback is essential for dynamic automation processes. For fluid-based applications (e.g., cooling systems), choose a thermistor with t₀.₉=0.15s in water flow (V=0.4 m/s). For airflow monitoring (e.g., HVAC in automation facilities), opt for t₀.₉=10s in airflow (V=2 m/s) to ensure timely adjustments.

Customization Options for Industrial Automation Needs

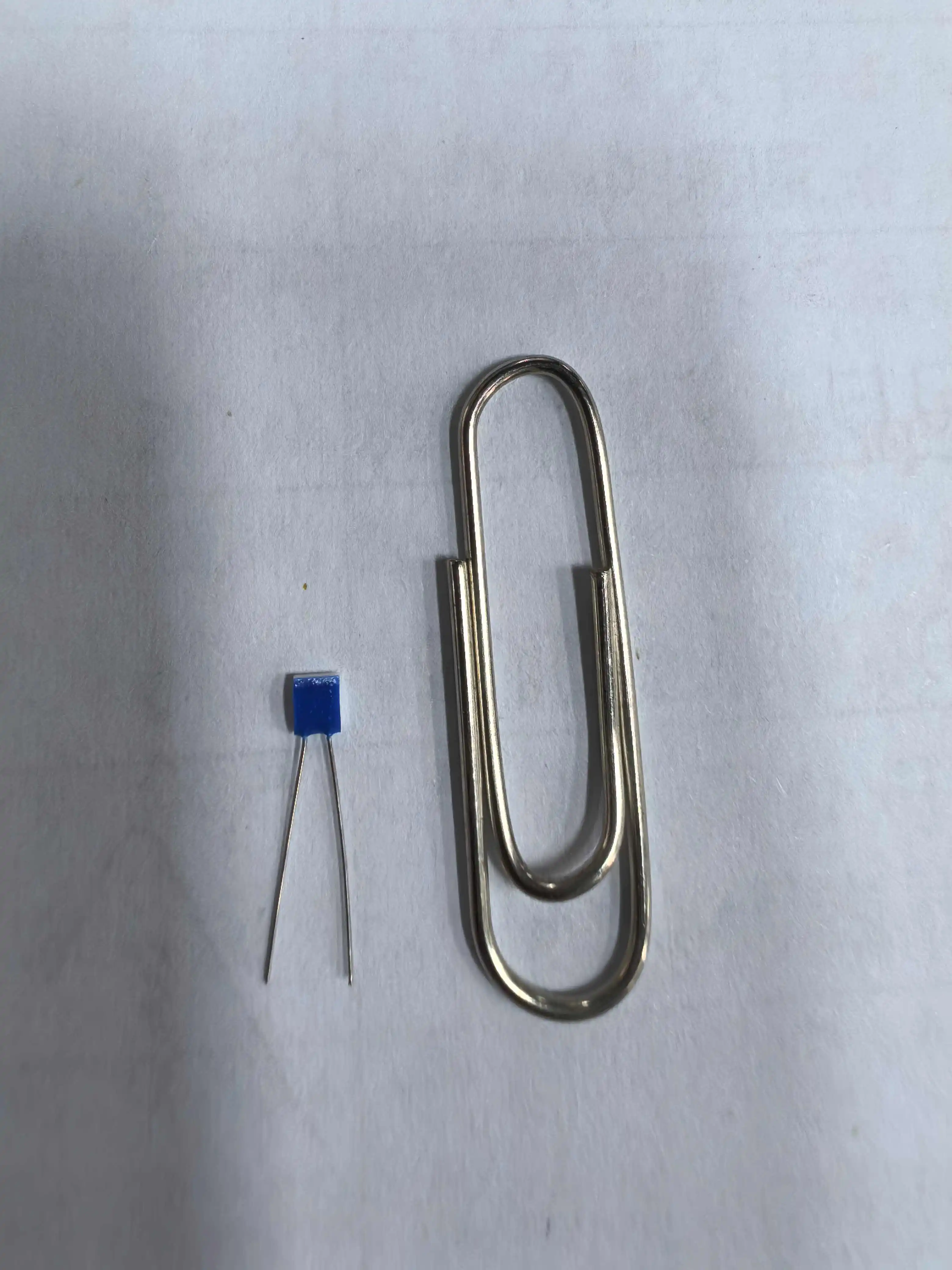

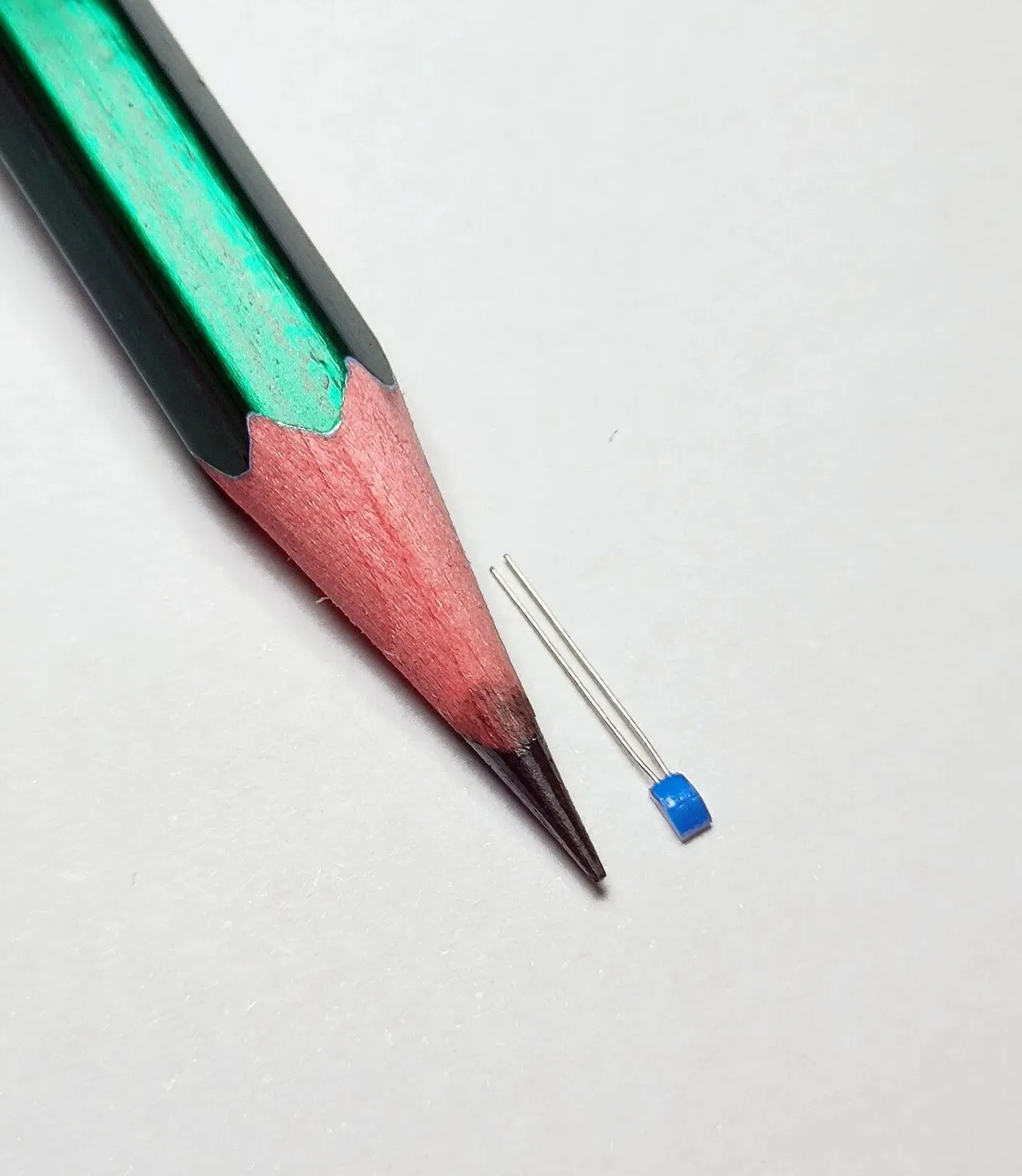

Every automation system is unique, so flexibility in sensor design is key. Our platinum resistance thermistors offer multiple customization options to fit your setup: lead materials (platinum-nickel, silver-palladium, pure platinum, or pure silver) and packaging (vacuum plastic or custom formats). For example, if your automation line uses corrosive materials, silver-palladium leads provide better corrosion resistance than standard platinum-nickel.

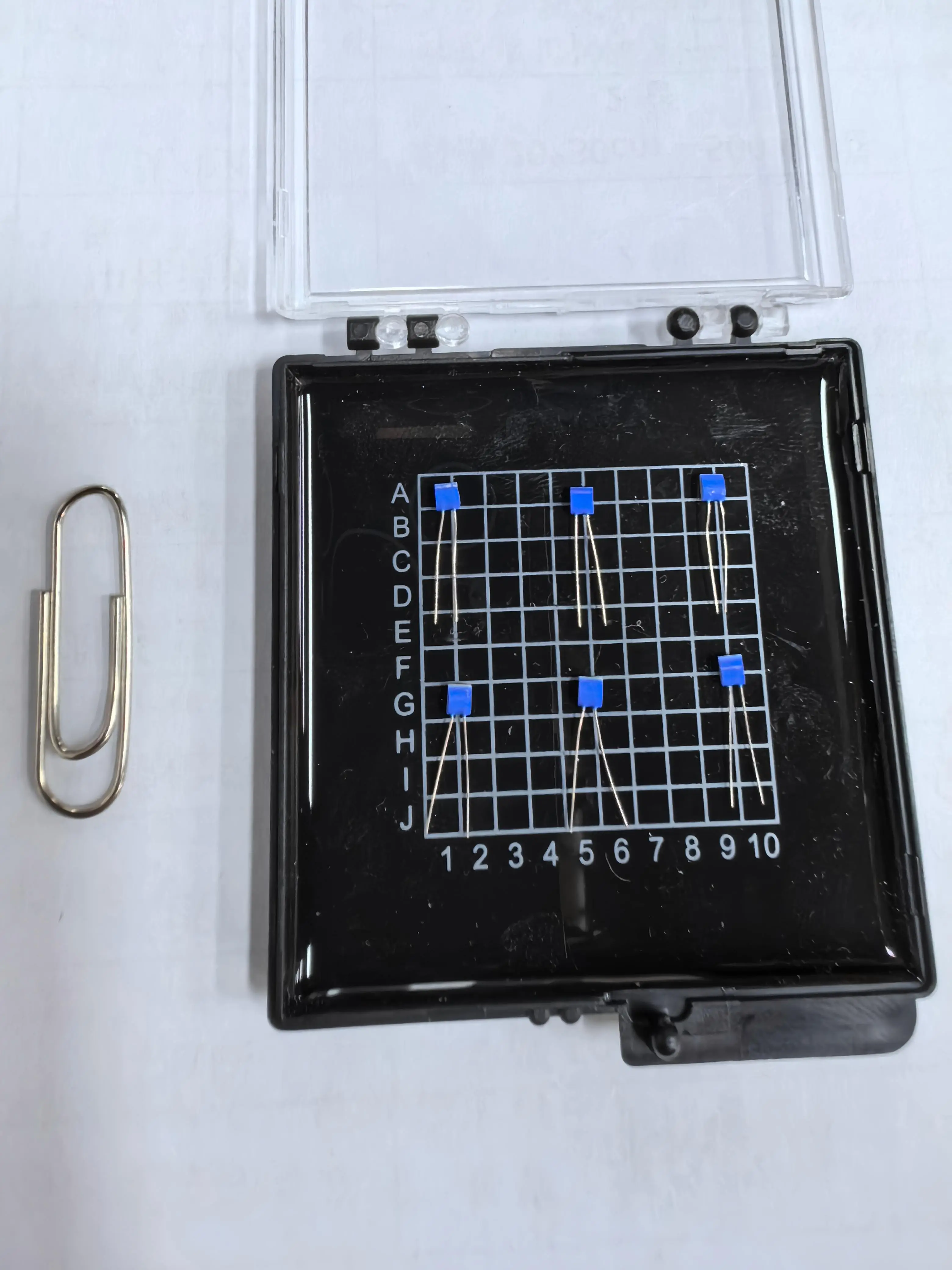

Lead specifications (10mm length, 0.2mm diameter) are standard, but we can adjust these to fit tight spaces in your automation equipment. This customization ensures seamless integration, avoiding the need for costly modifications to your existing system.

FAQ: Choosing Platinum Resistance Thermistors for Automation

Q: What’s the difference between platinum resistance thermistors and thermocouples for automation? A: Platinum RTDs offer higher accuracy and stability in moderate temperature ranges (common in most automation), while thermocouples are better for extreme high temperatures. RTDs also require less frequent calibration.

Q: Do I need a custom platinum resistance thermistor for my unique automation setup? A: It depends on your specific needs. If your system has standard dimensions and environmental conditions, our off-the-shelf options work. For tight spaces, corrosive environments, or unique lead requirements, customization is recommended.

Q: How do I ensure the thermistor is compatible with my PLC? A: Our platinum resistance thermistors have standard electrical characteristics that are compatible with most PLCs. We also provide wiring guides to simplify integration.

Conclusion & CTA

Choosing the right platinum resistance thermistor for your industrial automation system requires evaluating your temperature range, mechanical environment, and integration needs. By focusing on stability, durability, and customization options, you can select a sensor that enhances process efficiency and reduces downtime.

Ready to find the perfect platinum resistance thermistor for your automation setup? Our team of experts is here to help. Fill out our online form to share your application details, and we’ll recommend the best solution—including free samples for testing. Don’t let the wrong sensor hold back your automation performance.

Author Information: [Zhao Liu] is a sensor technology consultant specializing in industrial automation. With a background in electrical engineering, he helps manufacturers select and integrate high-performance temperature sensors.

References: 1. ISA-TR100.00.01-2023. Guide to Temperature Measurement in Industrial Processes. 2. “Sensor Selection for Industrial Automation” – Robotics and Automation Society, 2024.

Xi'an Tongzeda Technology Co., Ltd. is a leading manufacturer and supplier of advanced thermistor technology, focusing on providing high-performance temperature sensors for demanding industrial applications. We have profound expertise in microsensor manufacturing, specific packaging technologies, and multi-sensor integration methods, which ensures the excellent performance and reliability of our thermistors. As a trusted supplier of precision temperature measurement solutions, we offer a complete thermistor system, including sensor chips, testing systems, and analysis software. Please feel free to contact our technical experts at any time. ventes11@xatzd.com Discuss your specific requirements for thermistors and learn how our advanced thermal resistor optimization and manufacturing capabilities can enhance the performance and reliability of your temperature measurement system.

Learn about our latest products and discounts through SMS or email