Understanding Pt100 Sensor Specifications

Temperature Coefficient and Measurement Range

The temperature coefficient (TCR) is a critical parameter when selecting a Pt100 sensor. It indicates how much the sensor's resistance changes with temperature. For instance, our SMD thin film platinum resistance thermistors boast a TCR of 3850 ppm/°C, adhering to the IEC60751 standard. This specification ensures high sensitivity and accuracy across a wide temperature range.

Speaking of temperature range, it's essential to choose a Pt100 sensor that can operate within your required measurement bounds. Our sensors cover an impressive span from -200°C to +850°C, with specific models like our SMD thin film variant operating from -50°C to +200°C. This versatility makes them suitable for various applications, from cryogenic processes to high-temperature industrial environments.

Accuracy and Long-Term Stability

Accuracy is paramount in temperature measurement. High-quality Pt100 sensors, like those manufactured by professional platinum resistor manufacturers, can achieve accuracies of ±0.01 Ω. This precision is crucial for applications requiring exact temperature control or monitoring.

Long-term stability is another vital factor to consider. It indicates how well the sensor maintains its calibration over time, especially under harsh conditions. Our sensors exhibit excellent stability, with a drift of ≤±0.06% in resistance at 0°C after 1000 hours at 200°C. This remarkable stability ensures reliable measurements over extended periods, reducing the need for frequent recalibration.

Physical Dimensions and Construction

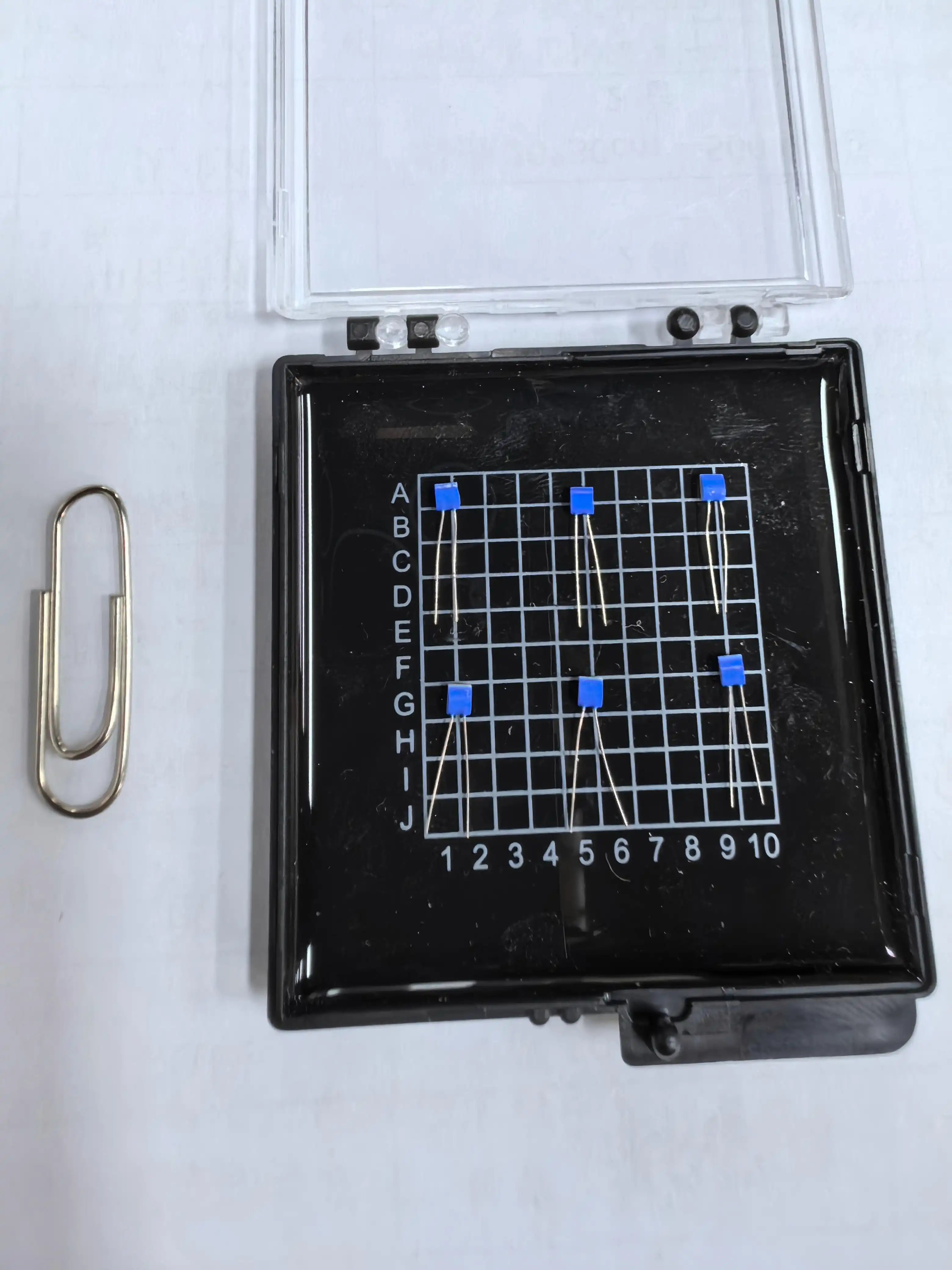

The size and construction of the Pt100 sensor play a significant role in its suitability for different applications. Our SMD thin film platinum resistance thermistors, for example, measure 3.2mm x 1.6mm x 0.7mm, making them ideal for space-constrained applications. We offer customizable options with sizes ranging from 1.2mm to 4.0mm to accommodate various installation requirements.

The sensor's construction also influences its durability and response time. Our sensors feature robust designs with vibration resistance up to 40g and impact resistance of 100g, ensuring reliability in demanding industrial, automotive, and aerospace applications. Moreover, with response times as low as 0.05 seconds, these sensors can capture rapid temperature changes accurately.

Compatibility and Integration Considerations

Terminal Types and Connectivity

When choosing a Pt100 sensor, it's crucial to consider how it will integrate with your existing systems. The terminal type plays a significant role in this aspect. Our sensors feature tin alloy terminals, which offer excellent conductivity and ease of connection. However, we also provide options with different lead materials, including platinum nickel, silver nickel, and pure platinum, to suit various application requirements.

The number of wires in the Pt100 sensor is another important consideration. Two-wire configurations are simpler but may suffer from lead resistance errors, especially over long distances. Three-wire and four-wire configurations offer improved accuracy by compensating for lead resistance, making them ideal for precision measurements or when the sensor is located far from the measurement instrument.

Soldering and Installation Methods

The installation method of the Pt100 sensor can significantly impact its performance and longevity. Our SMD thin film sensors are compatible with both reflow and wave soldering techniques, offering flexibility in manufacturing processes. We recommend using high-temperature solder paste and maintaining a soldering temperature between 230-240°C to ensure a robust and reliable connection.

For non-SMD sensors, consider the mounting options available. Some sensors may be designed for direct immersion in the medium being measured, while others might require a thermowell or other protective housing. The choice depends on the specific application requirements, including the need for quick response times, protection from corrosive environments, or ease of replacement.

Environmental Considerations

The environment in which the Pt100 sensor will operate is a crucial factor in the selection process. Consider factors such as humidity, vibration, electromagnetic interference, and exposure to corrosive substances. Our sensors, having undergone rigorous testing and certification processes including ISO9001, RoHS, and CE, are designed to withstand challenging industrial environments.

For applications involving extreme temperatures, high pressure, or corrosive media, specialized encapsulation or protective coatings may be necessary. Discuss these requirements with your sensor supplier to ensure you select a Pt100 sensor that can withstand the specific environmental challenges of your application.

Advanced Features and Technology Considerations

Thin Film Technology Advantages

The use of thin film technology in Pt100 sensors offers several advantages. Our thin film platinum resistor series employs advanced manufacturing techniques to achieve superior performance characteristics. The thin film construction allows for miniaturization without sacrificing accuracy, making these sensors ideal for applications where space is at a premium.

Thin film Pt100 sensors also exhibit excellent stability and repeatability. The precise deposition of the platinum film ensures uniformity in the sensing element, leading to more consistent measurements across the sensor's operational lifetime. This technology also allows for faster response times, as the thin film can quickly equilibrate with the surrounding temperature.

Multi-Sensor Integration and Smart Sensing

As industrial processes become more complex, there's an increasing demand for integrated sensing solutions. Some advanced Pt100 sensors can be part of multi-sensor packages that combine temperature measurement with other parameters such as pressure or humidity. This integration can simplify installation and reduce overall system complexity.

Furthermore, the advent of smart sensors with built-in signal conditioning and digital output capabilities is transforming temperature measurement. These advanced Pt100 sensors can provide direct digital output, self-diagnostics, and even wireless communication, enabling more sophisticated monitoring and control systems.

Calibration and Traceability

For applications requiring the highest level of accuracy, consider Pt100 sensors that come with calibration certificates traceable to national or international standards. This documentation ensures the sensor's performance has been verified against recognized benchmarks, providing confidence in the measurement results.

Some manufacturers offer sensors with built-in calibration data, stored either in the sensor itself or in accompanying documentation. This feature can simplify the integration process and ensure optimal accuracy across the sensor's operating range.

Conclusion

Choosing the right Pt100 sensor involves carefully considering various factors, from basic specifications like temperature range and accuracy to advanced features and environmental compatibility. By thoroughly evaluating these aspects, you can select a sensor that not only meets your current needs but also provides reliable performance over its entire lifecycle.

At Xi'an Tongzida Technology Co., Ltd., we specialize in manufacturing high-quality thin film temperature sensors that meet the most demanding requirements across various industries. Our commitment to innovation and quality ensures that our Pt100 sensors deliver exceptional accuracy, stability, and reliability.

For expert guidance on selecting the perfect Pt100 sensor for your application or to learn more about our advanced sensor solutions, please contact our team at sales11@xatzd.com. Our specialists are ready to assist you in finding the ideal temperature measurement solution for your unique needs.