Comprehending the Thin Film Platinum Resistor Pt300-DW

Core Features and Specifications

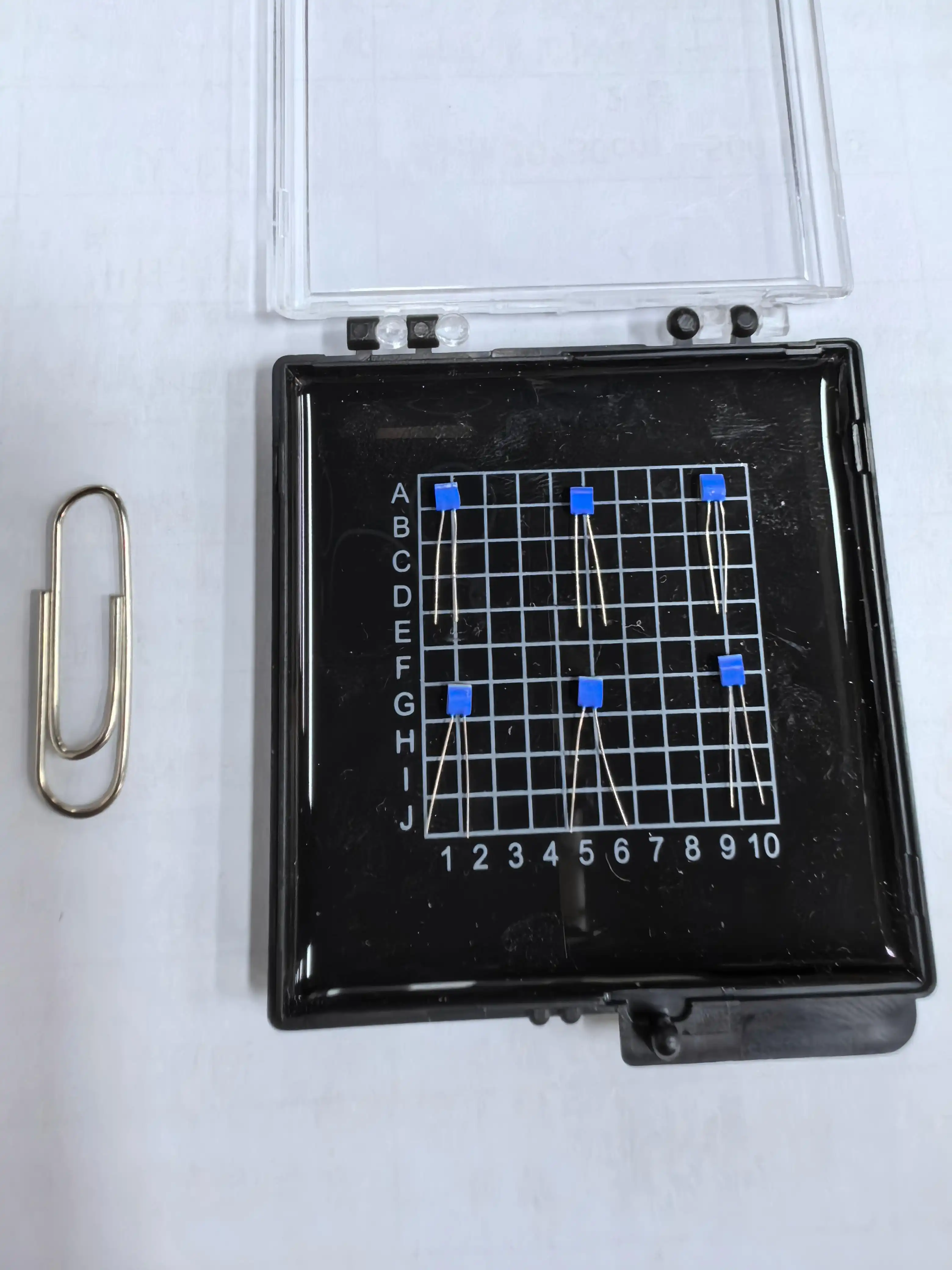

The Thin Film Platinum Resistor Pt300-DW is a marvel of modern sensor technology. Its compact dimensions of 2.0mm x 3.0mm x 1.0mm belie its powerful capabilities. The element type is a thin film platinum resistance thermistor, known for its exceptional accuracy and stability. The leads, measuring 10 mm in length and 0.2 mm in diameter, are crafted from platinum-nickel wire, with options for silver-palladium, platinum, or pure silver available to suit specific application needs.

One of the standout features of the Pt300-DW is its impressive lead tensile strength of ≥9 N, ensuring durability in challenging environments. The insulation resistance is equally noteworthy, maintaining 100 MΩ at 20°C and remaining above 2 MΩ even at elevated temperatures of 500°C. This exceptional insulation performance contributes to the sensor's reliability across a broad temperature spectrum.

Performance Characteristics

The Pt300-DW boasts a temperature coefficient (TCR) of 3850 ppm/°C, aligning with industry standards and ensuring compatibility with a wide range of measurement systems. Operating currents ranging from 0.1 to 0.8 mA provide flexibility in implementation, though users should be mindful of potential self-heating effects.

Long-term stability is a crucial factor in sensor selection, and the Pt300-DW excels in this regard. It demonstrates a resistance drift of ≤±0.04% of R₀ (0°C reference) after 1000 hours at 500°C, ensuring reliable measurements over extended periods. This stability is paramount in applications requiring continuous monitoring or where frequent recalibration is impractical.

Response time is another area where the Pt300-DW shines. In water flow conditions (V=0.4 m/s), it achieves a t₀.₅ of 0.05 s and a t₀.₉ of 0.15 s. For airflow applications (V=2 m/s), the response times are t₀.₅ = 3 s and t₀.₉ = 10 s. These rapid response characteristics make the Pt300-DW ideal for dynamic temperature measurement scenarios.

Applications and Advantages of the Pt300-DW

Versatility Across Industries

The Thin Film Platinum Resistor Pt300-DW finds applications across a diverse range of industries due to its exceptional performance characteristics. In industrial settings, it excels in process control and monitoring, where precise temperature measurements are critical for maintaining product quality and operational efficiency. The sensor's ability to withstand harsh environments makes it particularly suitable for use in chemical processing plants, refineries, and manufacturing facilities.

In the medical field, the Pt300-DW's accuracy and rapid response time make it invaluable for diagnostic equipment and patient monitoring systems. Its compact size allows for integration into minimally invasive medical devices, enabling real-time temperature measurements during procedures.

The automotive industry benefits from the Pt300-DW's robustness and wide temperature range. It finds applications in engine management systems, exhaust gas temperature monitoring, and battery thermal management in electric vehicles. The sensor's ability to withstand vibration and shock makes it ideal for these demanding automotive environments.

Aerospace applications leverage the Pt300-DW's high-temperature capabilities and long-term stability. It is used in aircraft engine monitoring, environmental control systems, and satellite thermal management. The sensor's reliability under extreme conditions ensures the safety and efficiency of critical aerospace systems.

Key Advantages Over Conventional Sensors

The Thin Film Platinum Resistor Pt300-DW offers several advantages over traditional temperature sensors. Its thin film construction allows for miniaturization without sacrificing performance, making it suitable for space-constrained applications. The platinum element ensures excellent linearity and stability over a wide temperature range, surpassing many other sensor types.

The Pt300-DW's fast response time is a significant advantage in dynamic temperature measurement scenarios. This rapid response enables more precise control in fast-changing thermal environments, improving overall system performance and efficiency.

Durability is another key strength of the Pt300-DW. With a vibration resistance of ≥40g acceleration across a frequency range of 10–2000 Hz and shock resistance of ≥100g acceleration (8 ms half-sine wave), it can withstand challenging industrial and automotive environments where lesser sensors might fail.

The sensor's self-heating coefficient of 0.4°C/mW (at 0°C) is relatively low, minimizing measurement errors due to internal heating. This characteristic is particularly valuable in applications requiring high accuracy or when using higher operating currents.

Implementation and Best Practices

Integration Considerations

When implementing the Thin Film Platinum Resistor Pt300-DW, several factors should be considered to ensure optimal performance. Proper thermal coupling between the sensor and the measured medium is crucial for accurate and responsive measurements. The sensor's small size allows for versatile mounting options, but care should be taken to minimize thermal gradients and ensure good thermal contact.

Circuit design plays a vital role in maximizing the Pt300-DW's capabilities. While the sensor can operate with currents between 0.1 and 0.8 mA, the choice of excitation current involves a trade-off between signal strength and self-heating effects. In applications requiring the highest accuracy, lower currents are preferable to minimize self-heating, while higher currents can be used where faster response times are prioritized.

The sensor's lead material options (platinum-nickel, silver-palladium, platinum, or pure silver) allow for customization based on the specific application requirements. Factors such as temperature range, chemical compatibility, and mechanical stress should guide the selection of lead material.

Calibration and Maintenance

To fully leverage the Pt300-DW's high accuracy potential, proper calibration is essential. While the sensor complies with IEC60751 standards, individual calibration can further enhance its accuracy. Multi-point calibration across the intended operating temperature range is recommended for applications requiring the highest precision.

The Pt300-DW's exceptional long-term stability reduces the frequency of recalibration compared to many other sensor types. However, periodic verification of calibration is still advisable, especially in critical applications or harsh environments. The sensor's resistance to drift, even after extended exposure to high temperatures, contributes to reduced maintenance requirements and lower total cost of ownership.

Proper handling and storage are important to maintain the sensor's performance. The vacuum plastic packaging provided offers protection during shipping and storage, but care should be taken during installation to avoid mechanical stress on the leads or sensing element. For applications in corrosive or contaminating environments, additional protective measures may be necessary to ensure long-term reliability.

Data Acquisition and Analysis

To fully utilize the Pt300-DW's capabilities, high-quality data acquisition systems are recommended. The sensor's wide temperature range and high accuracy potential necessitate measurement electronics with appropriate resolution and stability. For applications requiring the highest precision, consider using multi-wire configurations to eliminate lead resistance effects.

Data analysis software can enhance the value derived from the Pt300-DW's measurements. Advanced algorithms can compensate for any remaining non-linearities, apply digital filtering for noise reduction, and provide real-time statistical analysis of temperature data. This software-enhanced approach can unlock additional insights and improve overall system performance.

Conclusion

The Thin Film Platinum Resistor Pt300-DW represents a significant advancement in temperature measurement technology. Its combination of accuracy, stability, and durability makes it an excellent choice for a wide range of demanding applications. By carefully considering integration factors, maintaining proper calibration, and leveraging advanced data analysis techniques, users can maximize the benefits of this exceptional sensor. For more information about the Thin Film Platinum Resistor Pt300-DW and how it can enhance your temperature measurement capabilities, please contact us at sales11@xatzd.com.