Understanding the Fundamentals of Thin Film Platinum Resistors

The Structure and Composition of Thin Film Platinum Resistors

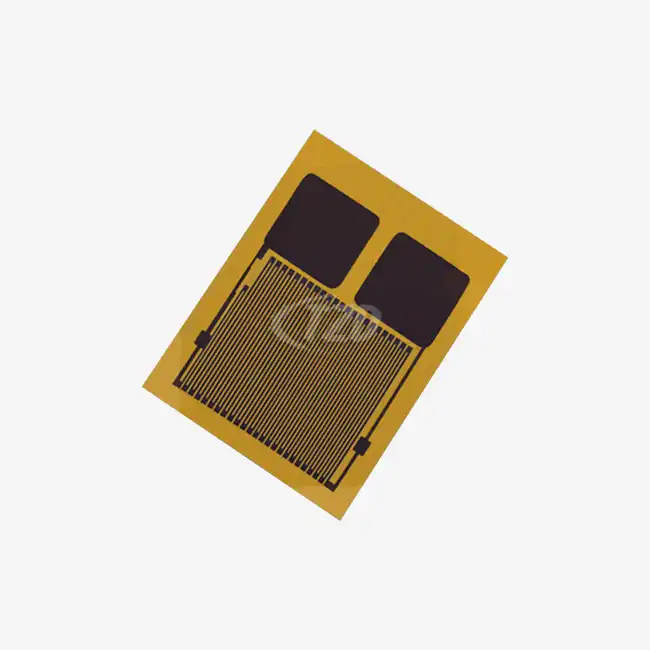

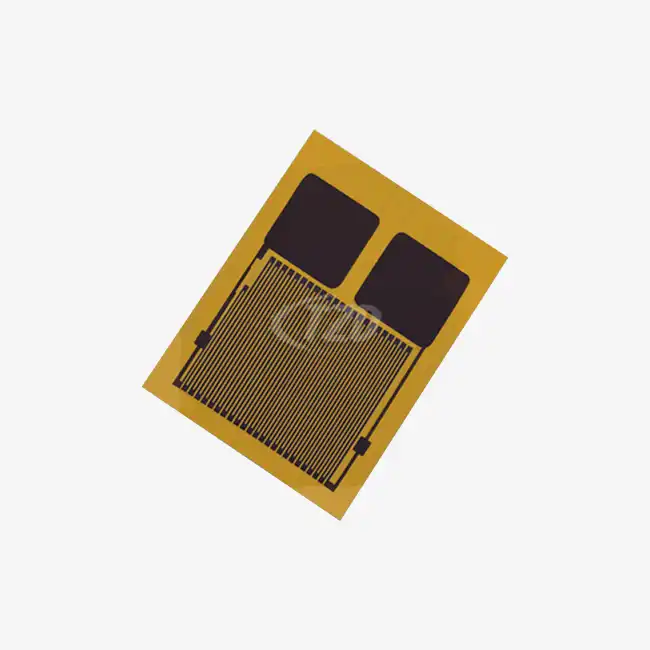

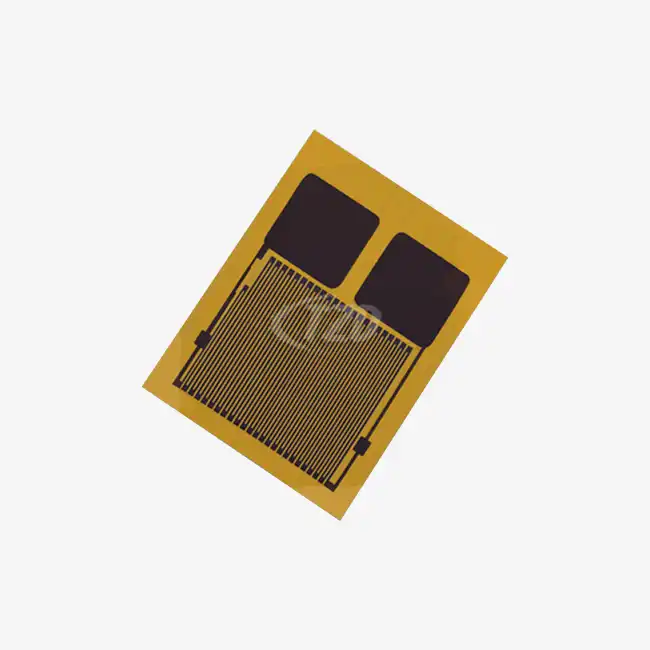

Thin film platinum resistors, such as the Pt1000-DW, are marvels of modern sensor technology. These devices consist of a thin layer of platinum deposited on a ceramic substrate, typically alumina. The platinum film, merely a few micrometers thick, is precisely etched to create a serpentine pattern that maximizes the resistive path within a compact area. This intricate design allows for a high resistance value in a small package, contributing to the sensor's responsiveness and accuracy.

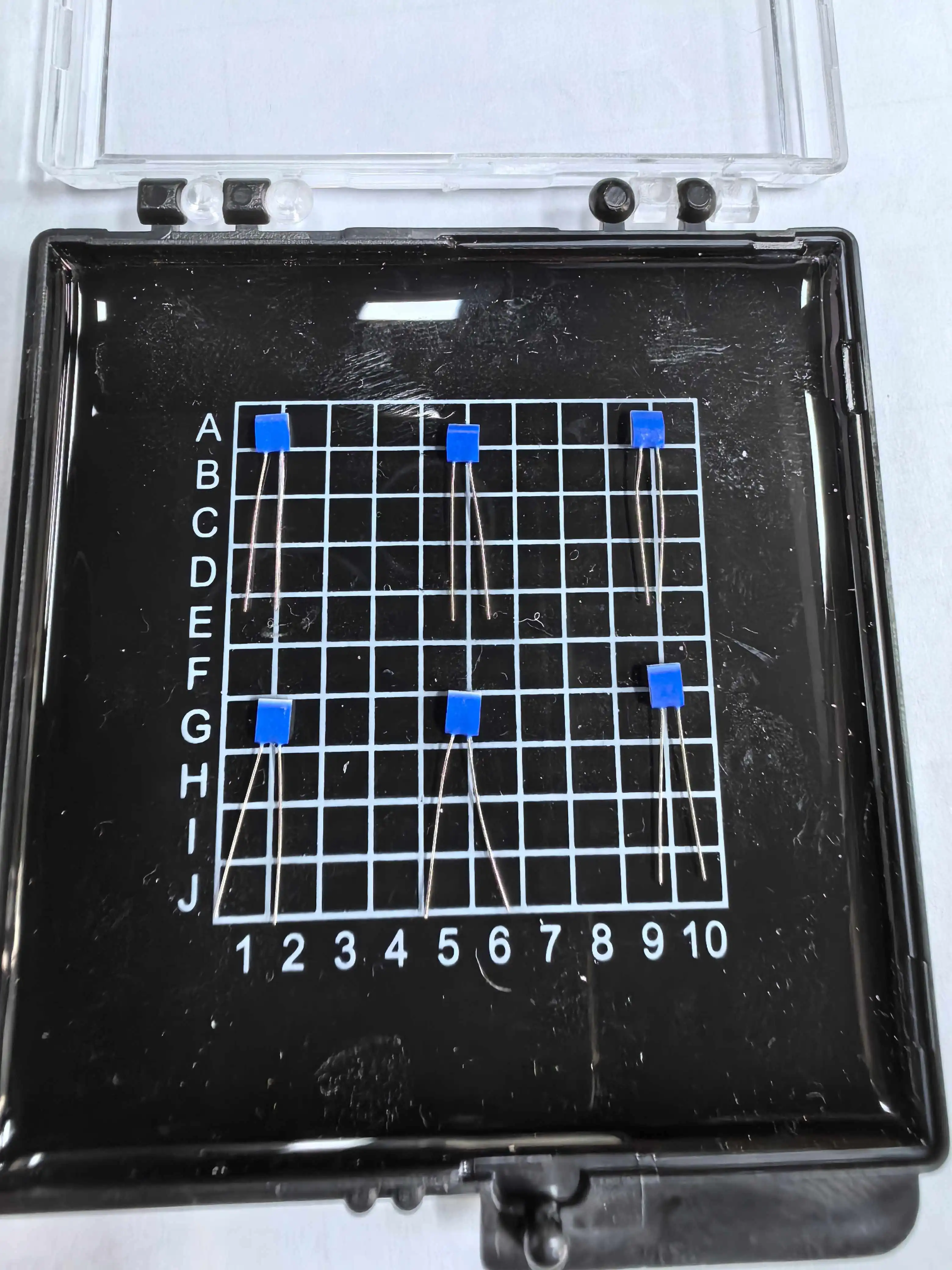

The Pt1000-DW, in particular, is available in various dimensions to suit different applications. Common sizes include 2.0mm x 2.3mm x 1.0mm and 2.0mm x 4.0mm x 1.0mm, showcasing the versatility of these sensors. The leads, crucial for connecting the sensor to measurement circuits, are typically 10 mm in length with a diameter of 0.2 mm. These leads are often made of platinum-nickel wire, though alternatives like silver-palladium, pure platinum, or pure silver are available for specific requirements.

The Temperature Coefficient of Resistance (TCR)

A critical characteristic of thin film platinum resistors is their Temperature Coefficient of Resistance (TCR). For the Thin Film Platinum Resistor Pt1000-DW, the TCR is 3850 ppm/°C, adhering to the IEC60751 standard. This value indicates that for every degree Celsius change in temperature, the resistance of the sensor changes by 0.385% of its base resistance at 0°C. This predictable and linear relationship between temperature and resistance forms the foundation of the sensor's operation.

The high TCR of platinum makes it an ideal material for temperature sensing, as it provides a significant and easily measurable change in resistance for small temperature variations. This sensitivity, combined with platinum's stability and resistance to corrosion, contributes to the sensor's accuracy and longevity.

The Mechanism of Temperature Sensing in Thin Film Platinum Resistors

Resistance Change with Temperature

The Thin Film Platinum Resistor Pt1000-DW operates on a simple yet elegant principle: as temperature increases, the vibration of atoms within the platinum lattice intensifies. This increased atomic motion impedes the flow of electrons through the metal, resulting in higher electrical resistance. Conversely, as temperature decreases, atomic vibrations diminish, allowing electrons to flow more freely and reducing the resistance.

This relationship between temperature and resistance is nearly linear over a wide range, typically from -200°C to +850°C for platinum resistors. The Pt1000-DW, with its nominal resistance of 1000 ohms at 0°C, provides a large resistance change per degree, making it particularly suitable for precise temperature measurements.

Response Time and Self-Heating Effects

The thin film construction of the Pt1000-DW contributes to its rapid response to temperature changes. In water flowing at 0.4 m/s, the sensor achieves a 50% response (t₀.₅) in just 0.05 seconds and a 90% response (t₀.₉) in 0.15 seconds. In airflow at 2 m/s, these times increase to 3 seconds and 10 seconds respectively, still remarkably quick for many applications.

However, the measurement process itself can introduce a small error due to self-heating. As current flows through the resistor, it generates heat, potentially raising the sensor's temperature above that of its surroundings. The Pt1000-DW has a self-heating coefficient of 0.4°C/mW at 0°C, necessitating careful consideration of the operating current. Typically, currents between 0.1 and 0.3 mA are used to balance measurement sensitivity with minimal self-heating effects.

Performance Characteristics and Applications of the Pt1000-DW

Accuracy and Stability

The Thin Film Platinum Resistor Pt1000-DW boasts impressive accuracy and stability characteristics. With an accuracy of ±0.01 Ω, these sensors provide highly precise temperature measurements. Their long-term stability is equally remarkable, with a resistance drift of ≤±0.04% of the reference resistance (R₀) at 0°C after 1000 hours of operation at 500°C. This exceptional stability ensures reliable measurements over extended periods, even in harsh environments.

The sensor's high insulation resistance, 100 MΩ at 20°C and >2 MΩ at 500°C, further contributes to its accuracy by minimizing current leakage. This characteristic, combined with the sensor's vibration resistance of ≥40g acceleration and shock resistance of ≥100g acceleration, makes the Pt1000-DW suitable for demanding industrial and aerospace applications.

Versatility in Extreme Conditions

Thin Film Platinum Resistor Pt1000-DW's wide operating temperature range, from -200°C to +850°C, showcases its versatility in extreme conditions. This broad range, coupled with its rapid response time and high accuracy, makes it an ideal choice for applications ranging from cryogenic systems to high-temperature industrial processes.

In aerospace applications, where sensors must withstand rapid temperature fluctuations and intense vibrations, the Pt1000-DW's robust construction and stability shine. Its small size allows for integration into compact spaces, while its resistance to shock and vibration ensures reliable operation in turbulent conditions.

For medical applications, the sensor's high accuracy and quick response time are crucial. In equipment such as blood analyzers or sterilization systems, precise temperature control is essential, and the Pt1000-DW delivers with its superior performance characteristics.

Customization and Integration

The flexibility of thin film platinum resistors extends to their customization options. Manufacturers like Xi'an Tongzida Technology Co., Ltd. offer the Pt1000-DW in various sizes, ranging from 1.2mm to 4.0mm, to suit different application requirements. The choice of lead materials, including platinum-nickel, silver-nickel, or pure platinum, allows for optimization based on specific environmental conditions or compatibility needs.

Integration of these sensors into larger systems is facilitated by their small size and standardized lead specifications. The vacuum plastic packaging protects the sensor during handling and installation, while alternative packaging options can be provided upon request to meet specific integration needs.

Conclusion

The Thin Film Platinum Resistor Pt1000-DW exemplifies the pinnacle of temperature sensing technology. Its precise response to temperature changes, coupled with its stability, accuracy, and durability, make it an indispensable component in a wide array of applications. As industries continue to demand more precise and reliable temperature measurements, sensors like the Pt1000-DW will play an increasingly crucial role in ensuring efficiency, safety, and quality across various sectors.

For those seeking to harness the capabilities of these advanced sensors in their applications, Xi'an Tongzida Technology Co., Ltd. stands ready to provide expert guidance and customized solutions. With their commitment to quality, evidenced by ISO9001, ROHS, and CE certifications, they offer a range of thin film platinum resistors tailored to meet the most exacting requirements. To explore how the Pt1000-DW or other thin film platinum resistors can enhance your temperature sensing capabilities, reach out to their team at sales11@xatzd.com.