Comprehending Pt500 RTD Chip Technology

Principles of Pt500 RTD Operation

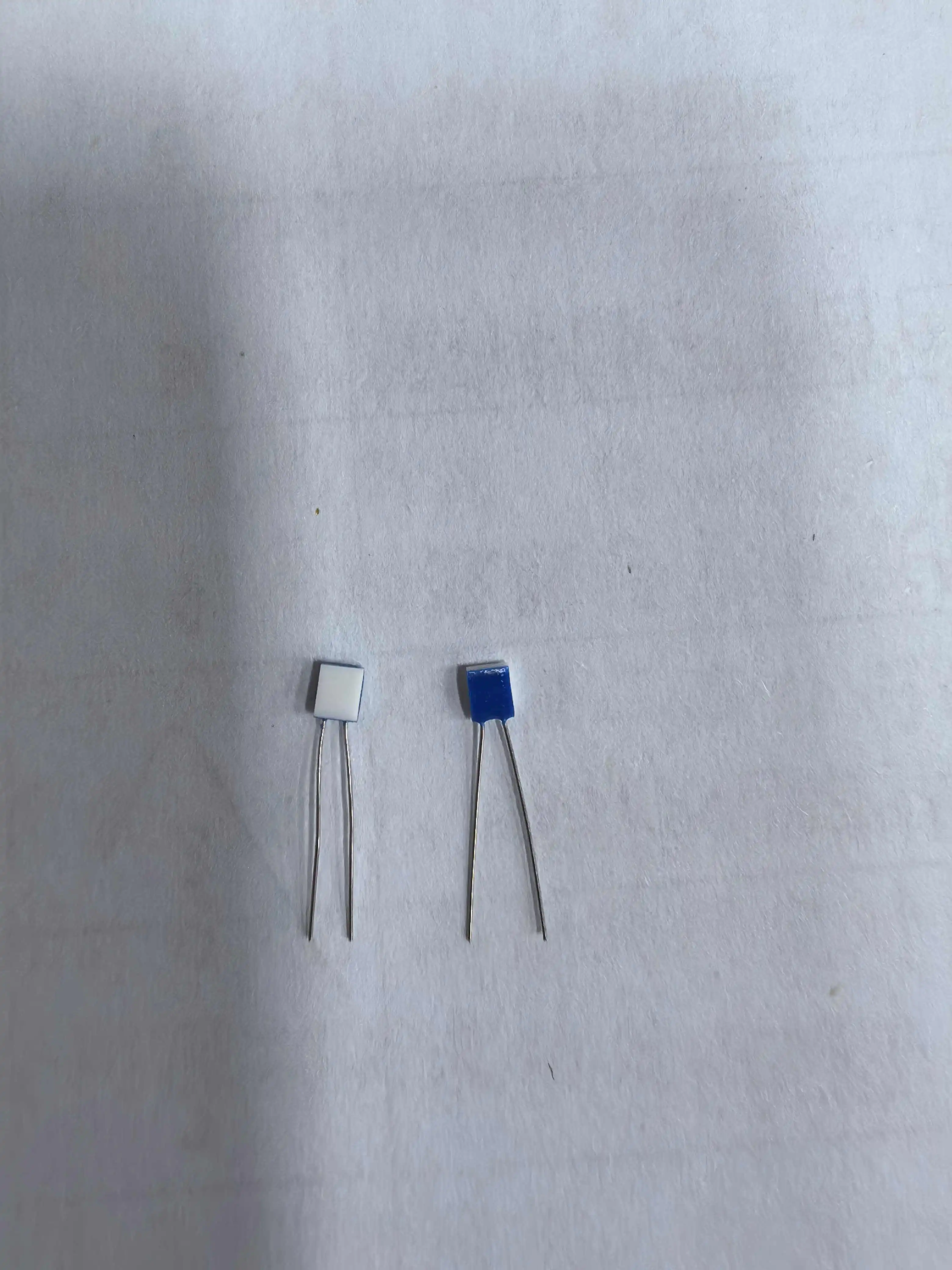

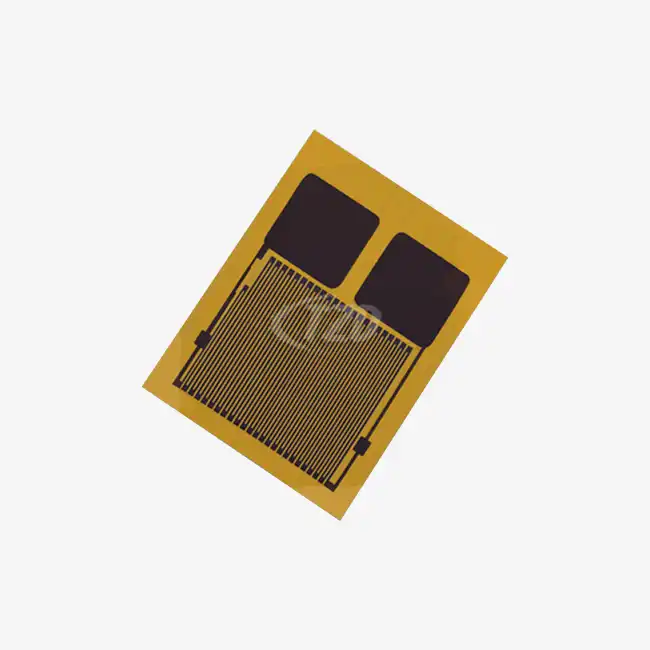

Pt500 RTD chips, or Platinum 500 Ohm Resistance Temperature Detectors, are sophisticated temperature sensing devices that leverage the predictable change in electrical resistance of platinum with temperature. These sensors typically consist of a thin platinum film deposited on a ceramic substrate, with precise dimensions and patterns to achieve the desired resistance characteristics.

The fundamental principle behind Pt500 RTD chips is the linear relationship between temperature and resistance in platinum. As temperature increases, the resistance of the platinum element rises proportionally. This relationship is characterized by the Temperature Coefficient of Resistance (TCR), which for high-quality Pt500 RTD chips is typically 3850 ppm/°C, in compliance with the IEC60751 standard.

Advantages of Thin Film Technology

Thin film technology used in Pt500 RTD chips offers several advantages over traditional wire-wound RTDs. The compact size of thin film elements allows for miniaturization, with typical dimensions as small as 2.0mm x 2.3mm x 1.0mm. This small footprint enables integration into space-constrained applications without compromising performance.

Moreover, thin film RTDs exhibit faster response times compared to their wire-wound counterparts. In water flow conditions (V=0.4 m/s), these sensors can achieve response times as low as t₀.₅ = 0.05 s and t₀.₉ = 0.15 s. This rapid response is crucial for applications requiring real-time temperature monitoring and control.

Customization Options for Pt500 RTD Chips

Custom Pt500 RTD chips offer a wide range of customization options to meet specific application requirements. These include:

- Element Dimensions: Customizable sizes ranging from 1.2mm to 4.0mm to fit various installation constraints.

- Lead Specifications: Adjustable lead lengths and diameters, with standard offerings of 10 mm length and 0.2 mm diameter.

- Lead Materials: Options include platinum-nickel wire, silver-palladium, pure platinum, or pure silver, each offering unique properties suitable for different environments.

- Temperature Range: Engineered to cover a wide temperature span from -200°C to +850°C, catering to both cryogenic and high-temperature applications.

- Packaging: Various packaging options available, including vacuum plastic packaging for enhanced protection during storage and handling.

Performance Characteristics of Custom Pt500 RTD Chips

Accuracy and Stability

Custom Pt500 RTD chips are engineered to deliver exceptional accuracy and long-term stability. These sensors can achieve an accuracy of ±0.01 Ω, translating to precise temperature measurements across their operating range. The long-term stability is equally impressive, with a drift of ≤±0.04% in resistance (R₀) after 1000 hours of operation at 500°C. This remarkable stability ensures reliable measurements over extended periods, reducing the need for frequent recalibration.

Environmental Resilience

Pt500 RTD chips are designed to withstand harsh environmental conditions, making them suitable for demanding applications. They exhibit excellent vibration resistance, capable of enduring ≥40g acceleration across a frequency range of 10-2000 Hz. Additionally, these sensors demonstrate robust shock resistance, withstanding ≥100g acceleration in an 8 ms half-sine wave. This durability ensures consistent performance in high-vibration environments such as industrial machinery or aerospace applications.

Electrical Characteristics

The electrical properties of custom Pt500 RTD chips are optimized for precise temperature sensing. With an operating current range of 0.1-0.7 mA, these sensors minimize self-heating effects while maintaining measurement accuracy. The self-heating coefficient of 0.4°C/mW (at 0°C) allows for precise compensation in applications where even minimal temperature deviations can be critical.

Insulation resistance is another crucial parameter, with these chips offering 100 MΩ at 20°C and maintaining >2 MΩ at elevated temperatures up to 500°C. This high insulation resistance ensures minimal current leakage and contributes to the overall accuracy of temperature measurements.

Applications and Industries Benefiting from Custom Pt500 RTD Chips

Industrial Process Control

In industrial settings, custom Pt500 RTD chips play a vital role in process control and monitoring. Their high accuracy and stability make them ideal for applications such as:

- Chemical reactors: Precise temperature control ensures optimal reaction conditions and product quality.

- Food and beverage processing: Maintaining specific temperatures during production and storage to ensure food safety and quality.

- Semiconductor manufacturing: Accurate temperature monitoring in critical processes like chemical vapor deposition and ion implantation.

The ability to withstand vibration and shock makes these sensors suitable for installation in industrial equipment operating in harsh environments.

Medical and Laboratory Equipment

The medical and laboratory sectors benefit significantly from the precision and reliability of custom Pt500 RTD chips. Applications include:

- Diagnostic equipment: Ensuring accurate temperature readings in blood analyzers and PCR machines.

- Incubators and sterilizers: Maintaining precise temperature control for cell cultures and medical instrument sterilization.

- Cryogenic storage: Monitoring ultra-low temperatures in biobanks and cryopreservation facilities.

The miniature size of these sensors allows for integration into compact medical devices without compromising performance.

Automotive and Aerospace

In the automotive and aerospace industries, custom Pt500 RTD chips find applications in:

- Engine management systems: Monitoring coolant and oil temperatures for optimal engine performance.

- Battery management in electric vehicles: Ensuring safe and efficient operation of lithium-ion battery packs.

- Aircraft environmental control systems: Regulating cabin temperature and managing thermal loads in avionics.

The sensors' ability to withstand high vibration and shock levels makes them suitable for these demanding environments.

Energy and Power Generation

Custom Pt500 RTD chips play a crucial role in energy and power generation applications, including:

- Solar thermal systems: Monitoring heat transfer fluid temperatures in concentrated solar power plants.

- Wind turbines: Temperature sensing in gearboxes and generators to prevent overheating.

- Nuclear power plants: Precise temperature monitoring in reactor cooling systems and safety circuits.

The long-term stability and wide temperature range of these sensors ensure reliable operation in critical energy infrastructure.

Research and Development

In research and development settings, custom Pt500 RTD chips are invaluable tools for:

- Materials science: Studying phase transitions and thermal properties of novel materials.

- Cryogenic research: Accurate temperature measurement in superconductivity and quantum computing experiments.

- Environmental monitoring: Precise temperature sensing in climate research and oceanography.

The high accuracy and customizable features of these sensors make them adaptable to a wide range of research applications.

Conclusion

Custom Pt500 RTD chips represent a pinnacle of temperature sensing technology, offering unparalleled accuracy, stability, and versatility across diverse applications. Their ability to be tailored to specific needs makes them invaluable in industries ranging from industrial process control to cutting-edge scientific research. As temperature measurement requirements become increasingly demanding, these sensors continue to evolve, pushing the boundaries of precision and reliability.

For those seeking to leverage the advantages of custom Pt500 RTD chips in their applications, expert guidance and support are essential. To explore how these advanced sensors can be optimized for your unique needs, please contact our team of specialists at sales11@xatzd.com. Our extensive experience in thin film temperature sensor technology ensures that you receive the most suitable solution for your temperature measurement challenges.