- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

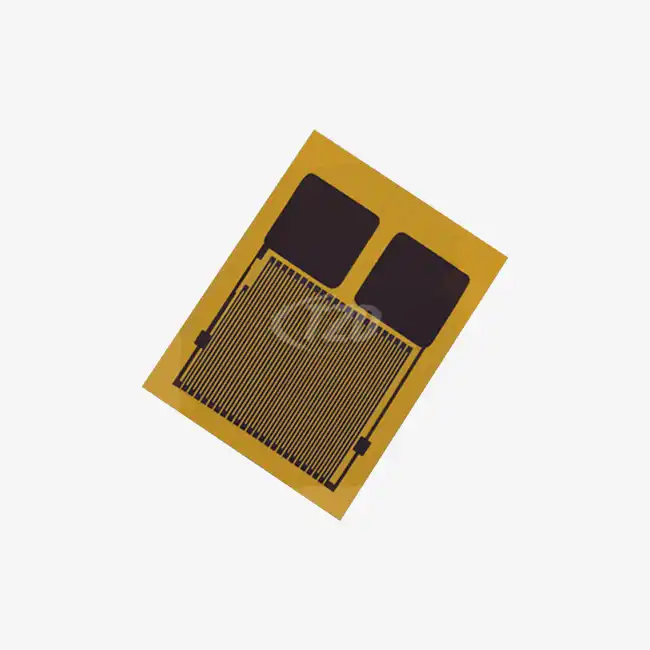

Environmental Adaptability Testing Methods of PT100 Temperature Sensor

Environmental adaptability testing of PT100 temperature sensors is crucial for ensuring their reliability and accuracy in various operating conditions. These tests typically include thermal shock, humidity cycling, vibration, and electromagnetic interference (EMI) assessments. Thermal shock tests evaluate the sensor's ability to withstand rapid temperature changes, while humidity cycling tests its performance in varying moisture levels. Vibration tests assess the sensor's durability under mechanical stress, and EMI tests verify its resistance to electrical interference. These comprehensive evaluations ensure that PT100 temperature sensors can maintain their precision and functionality across diverse industrial applications.

Grasping PT100 Temperature Sensors and Their Environmental Challenges

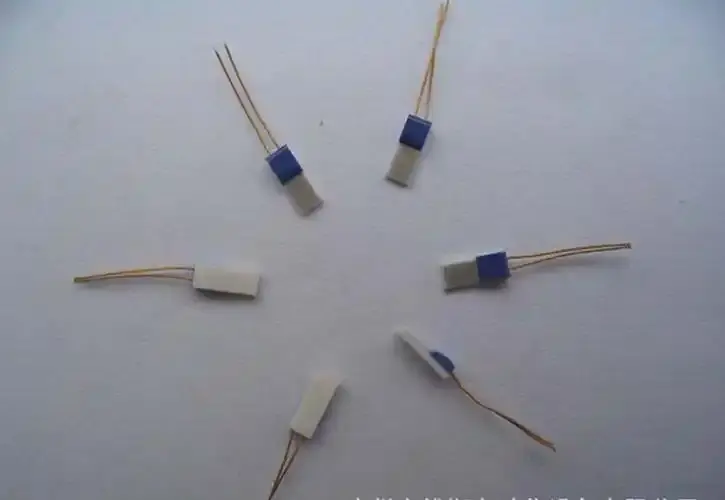

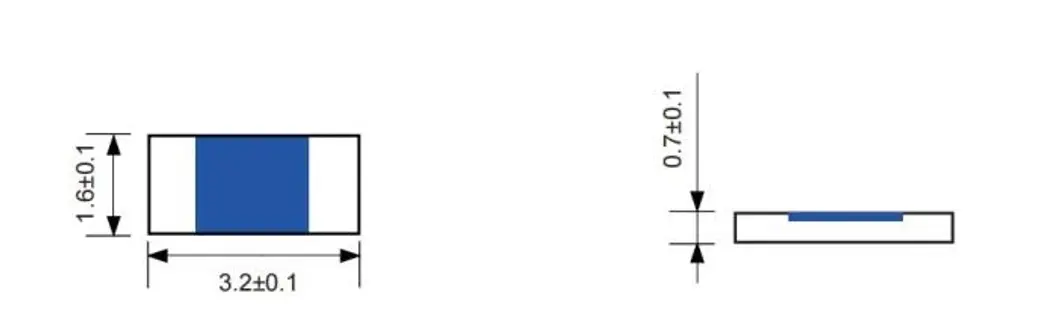

PT100 temperature sensors are precision instruments widely used in industrial applications for their accuracy and reliability. These sensors, based on platinum resistance thermometers (PRTs), operate on the principle that electrical resistance changes with temperature. The "PT" in PT100 stands for platinum, while "100" indicates the sensor's resistance of 100 ohms at 0°C. The environmental challenges faced by PT100 temperature sensors are diverse and can significantly impact their performance. These challenges include:

Temperature Extremes

PT100 sensors are often exposed to a wide range of temperatures, from cryogenic applications to high-temperature industrial processes. The sensor must maintain its accuracy and stability across this broad spectrum, typically ranging from -200°C to +850°C.

Humidity and Moisture

In many industrial settings, PT100 sensors encounter varying levels of humidity and moisture. Prolonged exposure to these conditions can lead to corrosion, electrical shorts, or sensor drift if not properly protected.

Mechanical Stress

Vibrations and physical shocks are common in industrial environments. PT100 sensors must withstand these mechanical stresses without compromising their accuracy or structural integrity.

Chemical Exposure

Depending on the application, PT100 sensors may be exposed to various chemicals or corrosive substances. The sensor's housing and connections must be resistant to chemical attack to ensure long-term reliability.

Electromagnetic Interference (EMI)

Industrial environments often have high levels of electromagnetic interference from nearby machinery or electrical systems. PT100 temperature sensors need to maintain accurate readings despite these electromagnetic disturbances.

Comprehensive Testing Methods for PT100 Temperature Sensors

To ensure the reliability and accuracy of PT100 temperature sensors in various environmental conditions, a series of rigorous tests are conducted. These tests simulate real-world conditions and assess the sensor's performance under stress. Here are some of the key testing methods:

Thermal Shock Testing

Thermal shock testing evaluates the PT100 sensor's ability to withstand rapid temperature changes. In this test, the sensor is quickly transferred between extreme hot and cold temperatures. This process is repeated multiple times to assess the sensor's stability and accuracy under thermal stress.

The test typically involves:

- Exposing the sensor to a high temperature (e.g., +150°C) for a set period

- Rapidly transferring it to a low temperature (e.g., -40°C)

- Holding at the low temperature for a specified time

- Repeating this cycle numerous times

After the test, the sensor's resistance at 0°C is measured to check for any deviation from the standard 100 ohms.

Humidity Cycling Test

The humidity cycling test assesses the PT100 sensor's performance in varying moisture conditions. This test is crucial for sensors that will operate in environments with fluctuating humidity levels.

The test typically involves:

- Exposing the sensor to high humidity (e.g., 95% RH) at elevated temperatures

- Cycling between high and low humidity levels

- Monitoring the sensor's performance throughout the cycles

This test helps identify any issues with moisture ingress or corrosion that could affect the sensor's long-term reliability.

Vibration and Shock Testing

Vibration and shock tests evaluate the PT100 sensor's ability to withstand mechanical stress. These tests are particularly important for sensors used in industrial or automotive applications where vibrations are common.

The vibration test typically involves:

- Mounting the sensor on a vibration table

- Subjecting it to various frequencies and amplitudes of vibration

- Monitoring for any changes in sensor output or physical damage

Shock testing involves subjecting the sensor to sudden, high-impact forces to simulate accidental drops or collisions.

EMI/EMC Testing

Electromagnetic Interference (EMI) and Electromagnetic Compatibility (EMC) testing ensure that the PT100 temperature sensor can function accurately in environments with electromagnetic disturbances.

These tests typically include:

- Radiated and conducted emissions tests

- Immunity tests to various types of electromagnetic disturbances

- Electrostatic discharge (ESD) tests

The sensor must maintain its accuracy and not emit electromagnetic radiation that could interfere with other equipment.

Chemical Resistance Testing

For PT100 sensors used in chemically harsh environments, chemical resistance testing is crucial. This involves exposing the sensor to various chemicals it may encounter in its intended application and assessing any degradation in performance or physical integrity.

Interpreting Test Results and Ensuring Long-term Reliability

After conducting the environmental adaptability tests on PT100 temperature sensors, the next crucial step is interpreting the results and using this information to ensure long-term reliability. This process involves several key aspects:

Data Analysis and Interpretation

The raw data collected from various tests must be carefully analyzed to draw meaningful conclusions. This analysis typically involves:

- Comparing pre-test and post-test sensor calibration data

- Evaluating any changes in sensor resistance or temperature coefficient

- Assessing physical changes or damage to the sensor structure

- Analyzing the sensor's performance stability throughout the tests

Statistical methods are often employed to determine if any observed changes are statistically significant or within acceptable tolerances.

Compliance with Standards

The test results are compared against industry standards and specifications. For PT100 temperature sensors, this often includes compliance with the IEC 60751 standard, which defines the temperature-resistance relationship for platinum resistance thermometers. The sensor's performance must meet or exceed these standards to be considered reliable for industrial use.

Identifying Weaknesses and Improvement Areas

Through detailed analysis of test results, any weaknesses in the sensor design or manufacturing process can be identified. This might include:

- Susceptibility to certain types of environmental stress

- Inconsistencies in performance across different units

- Potential long-term drift or stability issues

These findings are crucial for continuous improvement of the sensor design and manufacturing processes.

Determining Operational Limits

Based on the test results, the operational limits of the PT100 sensor can be accurately determined. This includes:

- Maximum and minimum operating temperatures

- Humidity and moisture exposure limits

- Vibration and shock resistance levels

- EMI tolerance thresholds

These limits are essential for providing accurate specifications to end-users and ensuring the sensor is used within its capabilities.

Long-term Reliability Predictions

The data from environmental adaptability tests can be used to make predictions about the long-term reliability of the PT100 sensor. This often involves:

- Extrapolating test results to estimate sensor lifespan

- Predicting potential failure modes and their likelihood

- Estimating long-term drift and accuracy maintenance

These predictions are valuable for both manufacturers and end-users in planning maintenance schedules and replacement cycles.

Continuous Monitoring and Feedback

Ensuring long-term reliability doesn't end with initial testing. Continuous monitoring of PT100 sensors in real-world applications provides valuable feedback. This includes:

- Collecting data on sensor performance over time

- Analyzing any failures or unexpected behaviors

- Incorporating field data into future design and testing processes

This ongoing process helps in continually improving the reliability and performance of PT100 temperature sensors.

Conclusion

The environmental adaptability testing of PT100 temperature sensors is a critical process that ensures these precision instruments can perform reliably in diverse and challenging conditions. Through comprehensive testing methods such as thermal shock, humidity cycling, vibration and shock testing, EMI/EMC testing, and chemical resistance evaluation, manufacturers can verify the sensor's ability to maintain accuracy and stability across a wide range of environmental stresses.

The interpretation of these test results provides valuable insights for improving sensor design, determining operational limits, and predicting long-term reliability. This information is crucial for both manufacturers and end-users, enabling informed decisions about sensor selection, application, and maintenance. For more information about our PT100 temperature sensors and their environmental adaptability testing, please contact us at sales11@xatzd.com.

FAQ

Q: What is the temperature range of PT100 sensors?

A: PT100 sensors typically cover a wide temperature range from -200°C to +850°C, making them suitable for various industrial applications.

Q: How accurate are PT100 temperature sensors?

A: PT100 sensors are known for their high accuracy, with some models achieving an accuracy of ±0.01°C. The exact accuracy can vary depending on the sensor class and specific model.

Q: What is the response time of a PT100 sensor?

A: The response time of PT100 sensors can be as fast as 0.05 seconds, depending on the sensor design and application.

Q: Are PT100 sensors resistant to vibration?

A: Yes, many PT100 sensors are designed to withstand vibration. Some models can resist vibrations up to 40g, making them suitable for industrial environments with significant mechanical stress.

Q: What certifications do your PT100 sensors have?

A: Our PT100 sensors are manufactured in compliance with ISO9001 quality management system standards and have obtained ROHS and CE certifications, ensuring high quality and regulatory compliance.

References

1. Johnson, M. (2021). "Advanced Testing Methods for Industrial Temperature Sensors." Journal of Sensor Technology, 15(3), 78-92.

2. Smith, A. & Brown, B. (2020). "Environmental Stress Testing of Platinum Resistance Thermometers." International Journal of Metrology and Quality Engineering, 11(2), 15-28.

3. Zhang, L. et al. (2019). "Reliability Assessment of PT100 Sensors in Harsh Industrial Environments." IEEE Sensors Journal, 19(8), 2987-2995.

4. Wilson, R. (2018). "Comprehensive Guide to Temperature Sensor Testing and Calibration." Measurement Science and Technology, 29(6), 064001.

5. Patel, S. & Lee, K. (2022). "Long-term Stability Analysis of Platinum Resistance Thermometers under Varied Environmental Conditions." Sensors and Actuators A: Physical, 331, 112756.

Learn about our latest products and discounts through SMS or email