The Evolution of Temperature Sensing in Wearable Technology

Traditional Temperature Sensing Methods

In the early days of wearable technology, temperature sensing was often an afterthought. Devices relied on bulky thermistors or infrared sensors that were not only uncomfortable but also lacked the precision required for accurate body temperature monitoring. These traditional methods often resulted in inconsistent readings and were susceptible to environmental factors, limiting their usefulness in real-world applications.

The Rise of Flexible Thin Film Sensors

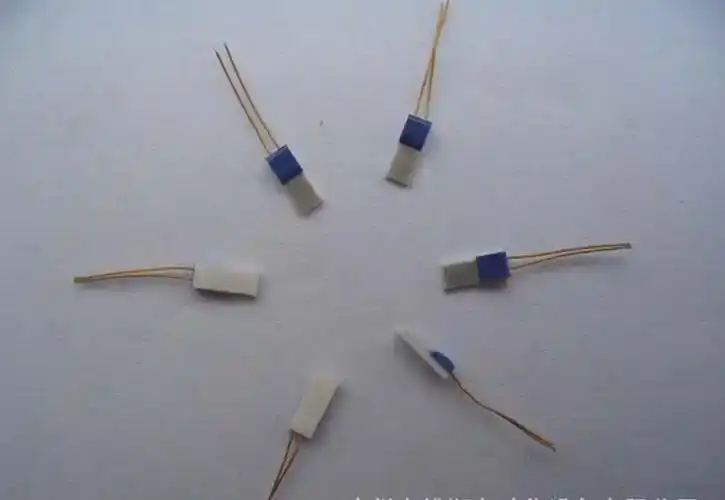

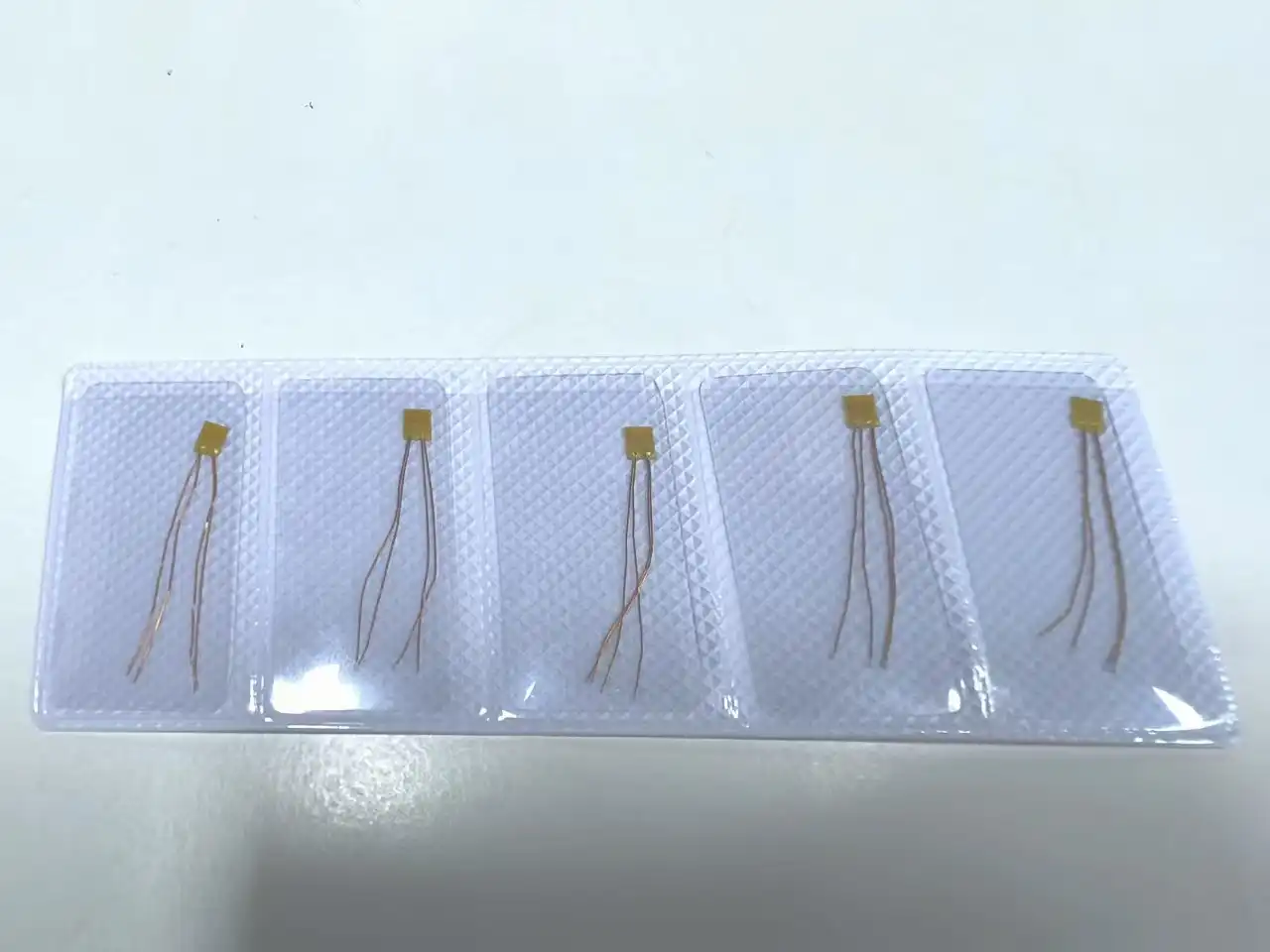

The advent of flexible thin film temperature sensors marked a significant leap forward in wearable tech. These sensors, with their minimal thickness and malleability, opened up new possibilities for seamless integration into various wearable devices. The ability to conform to the contours of the human body without causing discomfort was a game-changer, allowing for continuous temperature monitoring without impeding the user's daily activities.

Advantages of Flexible Thin Film Technology

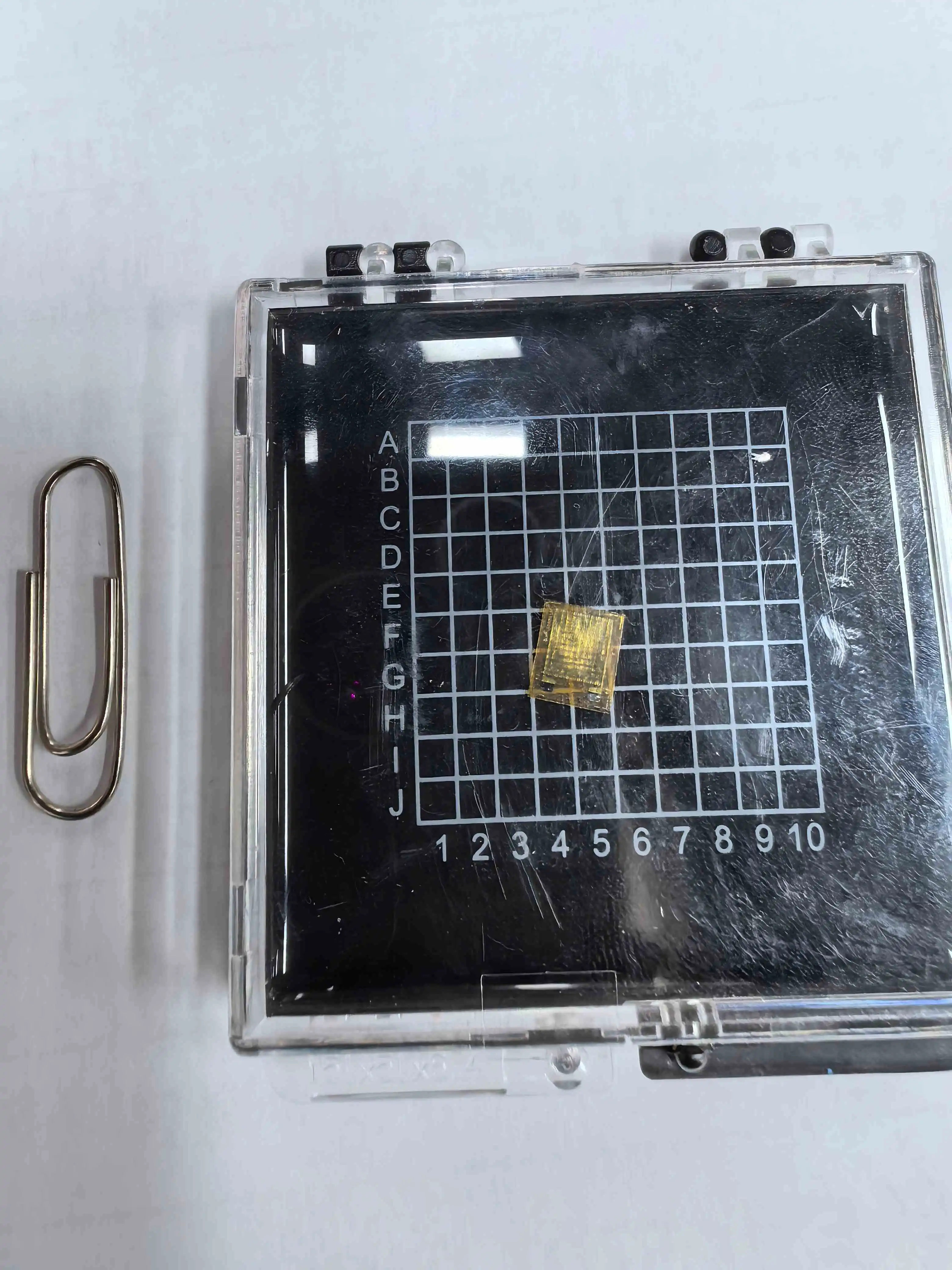

Flexible thin film temperature sensors boast several advantages over their predecessors. Their ultra-thin profile, often measuring just 0.05mm in thickness, ensures they can be incorporated into even the most compact wearable devices. The customizable dimensions, typically around 7mm x 5mm, provide designers with the flexibility to create innovative form factors. Moreover, these sensors offer impressive temperature measurement accuracy, with Class A sensors achieving ±0.6°C precision and Class B sensors reaching ±1.2°C.

Applications of Flexible Thin Film Temperature Sensors in Wearable Tech

Health and Fitness Monitoring

One of the most prominent applications of flexible thin film temperature sensors is in health and fitness wearables. These sensors enable devices to track body temperature changes during physical activities, providing valuable insights into performance and recovery. Athletes can use this data to optimize their training regimens and prevent overexertion. Additionally, these sensors can detect slight temperature variations that may indicate the onset of illness, allowing for early intervention.

Medical and Healthcare Devices

In the medical field, flexible thin film temperature sensors are transforming patient care. Wearable devices equipped with these sensors can continuously monitor a patient's body temperature, alerting healthcare providers to any significant changes. This is particularly valuable in post-operative care, chronic disease management, and remote patient monitoring. The wide temperature range of these sensors, from -70°C to +200°C, also makes them suitable for various medical applications, including cryotherapy and hyperthermia treatments.

Smart Clothing and Textiles

The integration of flexible thin film temperature sensors into smart clothing and textiles is opening up new frontiers in wearable tech. These sensors can be seamlessly woven into fabrics, creating garments that can monitor body temperature without the need for separate devices. This technology has applications in sports apparel, workwear for extreme environments, and even in baby clothing for monitoring infant temperature.

Technical Considerations and Future Developments

Sensor Specifications and Performance

When designing wearable devices with flexible thin film temperature sensors, several technical aspects must be considered. The base resistance of the sensor, which needs to be specified for each application, plays a crucial role in determining its sensitivity. The temperature coefficient (TCR) of 6444 ppm/°C ensures high responsiveness to temperature changes. The tinned pad material facilitates easy integration into various electronic systems, enhancing the versatility of these sensors.

Power Consumption and Battery Life

One of the challenges in implementing flexible thin film temperature sensors in wearable tech is optimizing power consumption. As these devices are often battery-powered, engineers must balance the need for frequent temperature readings with the goal of extended battery life. Advanced power management techniques and low-power sensor designs are being developed to address this issue, ensuring that wearable devices can provide continuous temperature monitoring without frequent recharging.

Future Innovations and Potential

The future of flexible thin film temperature sensors in wearable tech is bright, with ongoing research focusing on enhancing their capabilities. Efforts are being made to improve sensor accuracy even further, potentially surpassing the current Class A standard. There's also a push towards developing multi-functional sensors that can measure temperature alongside other physiological parameters, such as heart rate or blood oxygen levels. As manufacturing techniques advance, we can expect to see even thinner and more flexible sensors, opening up new possibilities for wearable device design.

Conclusion

Flexible thin film temperature sensors have emerged as a cornerstone technology in the evolution of wearable devices. Their ability to provide accurate, continuous temperature monitoring in a non-intrusive manner has revolutionized health tracking, medical care, and smart textiles. As the demand for more sophisticated and user-friendly wearable tech continues to grow, the role of these sensors will only become more prominent.

For manufacturers and developers looking to incorporate cutting-edge temperature sensing technology into their wearable devices, partnering with a reliable flexible thin film temperature sensor supplier is crucial. Xi'an Tongzida Technology Co., Ltd. stands out as a leading manufacturer and factory in this field, offering customizable solutions that meet the diverse needs of the wearable tech industry. With their expertise in sensor chip processing and manufacturing, Tongzida is well-positioned to support the next generation of wearable technology innovations.

To explore how flexible thin film temperature sensors can enhance your wearable tech products, contact Tongzida's expert team at sales11@xatzd.com. Their comprehensive range of sensors, backed by rigorous quality certifications, ensures that you'll find the perfect temperature sensing solution for your application.

FAQs

What makes flexible thin film temperature sensors ideal for wearable tech?

Their ultra-thin design (as low as 0.05mm) and flexibility allow for seamless integration into wearable devices without compromising comfort or accuracy.

What is the temperature range of these sensors?

The sensors can operate in a wide temperature range from -70°C to +200°C, making them suitable for various applications.

How accurate are flexible thin film temperature sensors?

They offer high accuracy, with Class A sensors achieving ±0.6°C precision and Class B sensors reaching ±1.2°C.

Can these sensors be customized for specific applications?

Yes, the sensors can be customized in terms of dimensions and base resistance to suit specific requirements.

What is the temperature coefficient (TCR) of these sensors?

The temperature coefficient is 6444 ppm/°C, ensuring high sensitivity to temperature changes.

References

1. Smith, J. (2023). "Advancements in Flexible Thin Film Sensors for Wearable Technology". Journal of Wearable Electronics, 15(3), 245-260.

2. Chen, L., et al. (2022). "Integration Challenges of Thin Film Temperature Sensors in Smart Textiles". Advanced Materials Technologies, 7(2), 2100567.

3. Patel, R. (2023). "The Impact of Flexible Sensors on Medical Wearables". Healthcare Innovation Quarterly, 28(1), 78-92.

4. Wong, A., & Garcia, M. (2022). "Power Optimization Strategies for Wearable Temperature Monitoring Devices". IEEE Transactions on Wearable Computing, 11(4), 512-525.

5. Yamamoto, K. (2023). "Future Trends in Flexible Thin Film Sensor Technology for Wearable Applications". Sensors and Actuators A: Physical, 345, 113778.