Understanding the Technology Behind High-Stability Pt1000 Sensors

Principles of Platinum Resistance Thermometry

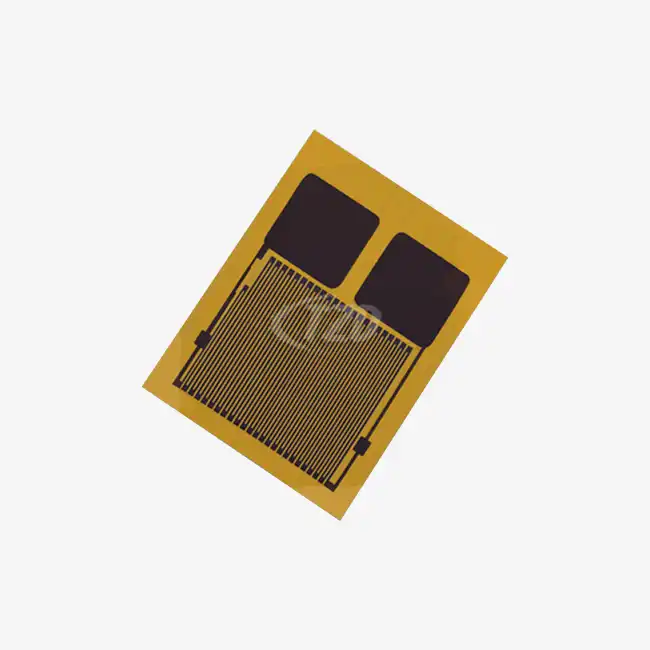

Platinum resistance thermometry forms the backbone of High-Stability Pt1000 Sensors. This technology leverages the predictable change in electrical resistance of platinum with temperature variations. The "1000" in Pt1000 denotes the sensor's nominal resistance of 1000 ohms at 0°C, providing a wider resistance range and enhanced sensitivity compared to its Pt100 counterparts.

The platinum element in these sensors exhibits a nearly linear relationship between resistance and temperature, making it ideal for precise measurements. With a temperature coefficient (TCR) of 3850 ppm/°C, Pt1000 sensors offer excellent resolution and accuracy across a broad temperature range, particularly beneficial in medical settings where even slight temperature deviations can be critical.

Design and Construction of High-Stability Pt1000 Sensors

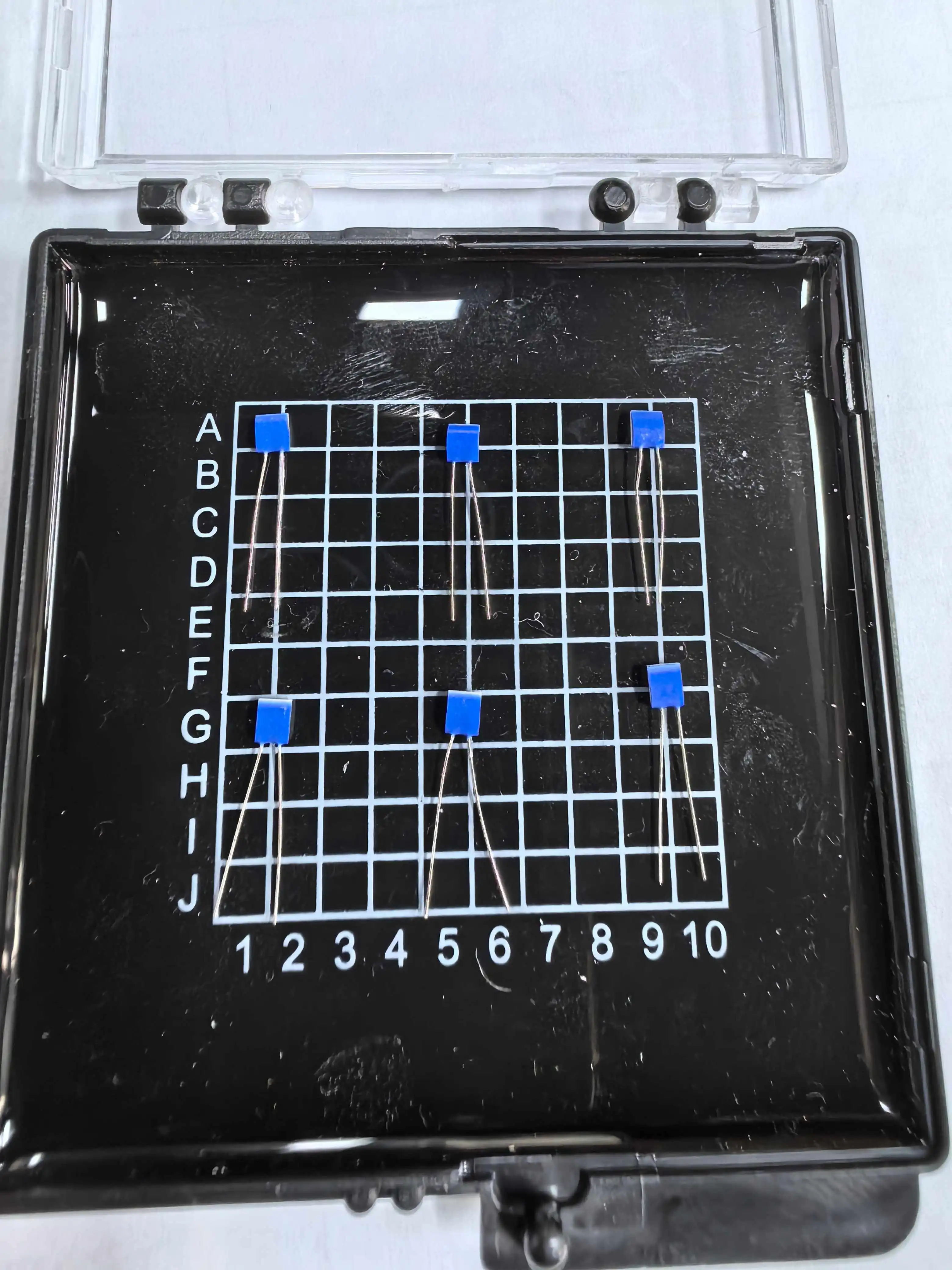

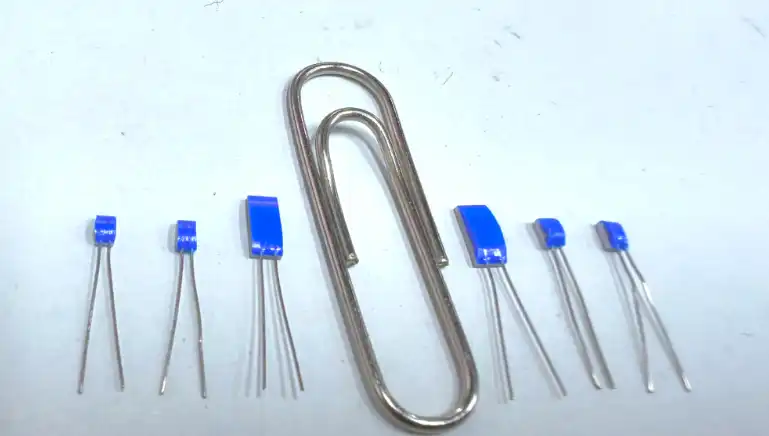

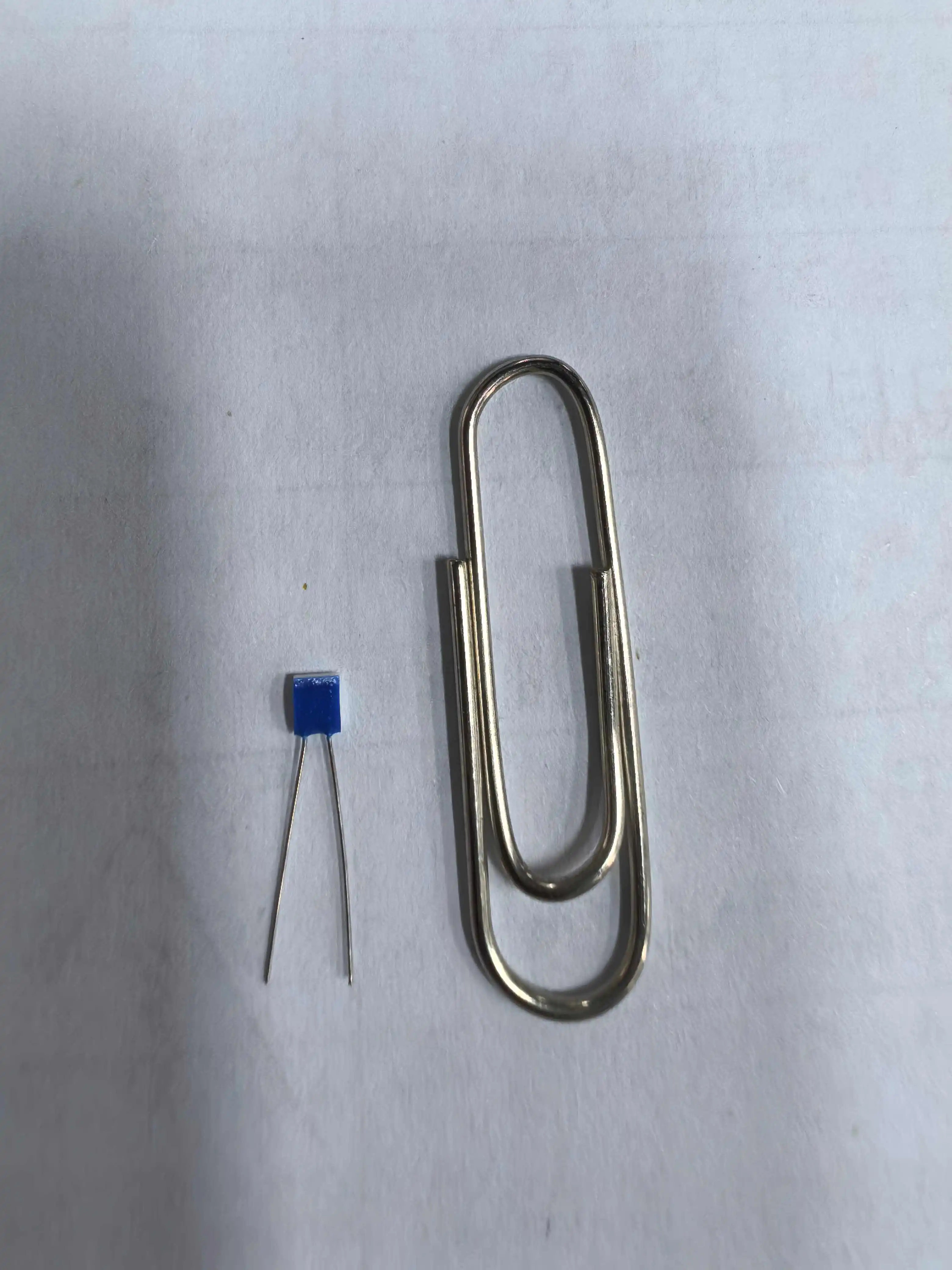

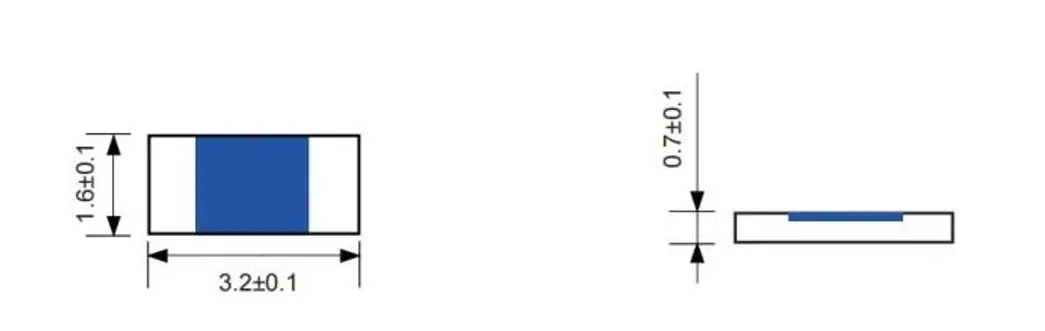

High-Stability Pt1000 Sensors are meticulously crafted to ensure optimal performance in medical applications. The sensing element typically measures 2.0mm x 2.3mm x 1.0mm or 2.0mm x 4.0mm x 1.0mm, allowing for integration into compact medical devices. The lead wires, usually 10 mm in length with a 0.2 mm diameter, are made of platinum-nickel alloy, though silver-palladium, platinum, or pure silver options are available for specific requirements.

The sensor's construction emphasizes durability, with lead tensile strength of ≥9 N and impressive vibration resistance of ≥40g acceleration across a 10-2000 Hz frequency range. This robustness ensures reliable operation even in environments prone to mechanical stress, such as portable medical equipment or during patient transport.

Key Performance Characteristics

Several performance metrics set High-Stability Pt1000 Sensors apart in medical applications. The insulation resistance, 100 MΩ at 20°C and >2 MΩ at 500°C, guarantees electrical integrity across a wide temperature range. The sensor's long-term stability is remarkable, with ≤±0.04% resistance drift of R₀ (0°C reference) after 1000 hours at 500°C, ensuring consistent readings over extended periods.

Response times are crucial in medical scenarios, and these sensors excel with t₀.₅ = 0.05 s and t₀.₉ = 0.15 s in water flow (V=0.4 m/s), and t₀.₅ = 3 s and t₀.₉ = 10 s in airflow (V=2 m/s). The self-heating coefficient of 0.4°C/mW (at 0°C) minimizes measurement errors due to the sensor's own heat generation, a critical factor in precise temperature monitoring.

Applications of High-Stability Pt1000 Sensors in Medical Fields

Critical Care and Patient Monitoring

In critical care units, High-Stability Pt1000 Sensors play a vital role in continuous patient temperature monitoring. Their rapid response times and high accuracy enable healthcare providers to detect fever spikes or hypothermia quickly, facilitating prompt intervention. These sensors are often integrated into multiparameter monitors, contributing to comprehensive patient assessment alongside other vital signs.

The sensors' stability and resistance to interference from electromagnetic fields make them ideal for use in neonatal intensive care units, where maintaining precise temperature control is crucial for premature infants. Their compact size allows for non-invasive skin temperature monitoring, minimizing discomfort while ensuring accurate readings.

Medical Imaging and Diagnostic Equipment

High-Stability Pt1000 Sensors find extensive use in medical imaging technologies such as MRI machines, CT scanners, and PET systems. These devices require precise temperature control to maintain the integrity of sensitive electronic components and ensure patient comfort during scans. The sensors' ability to operate accurately in strong electromagnetic fields makes them particularly suitable for MRI environments.

In diagnostic equipment like blood analyzers and PCR machines, Pt1000 sensors enable precise temperature regulation crucial for accurate test results. Their fast response times and long-term stability contribute to the reliability of these instruments, ensuring consistent performance across numerous test cycles.

Therapeutic Devices and Drug Delivery Systems

The application of High-Stability Pt1000 Sensors extends to various therapeutic devices. In hyper/hypothermia treatment systems, these sensors provide accurate temperature feedback, enabling precise control of patient body temperature. This is particularly critical in post-cardiac arrest care or during certain surgical procedures where targeted temperature management is essential.

In drug delivery systems, such as infusion pumps and insulin delivery devices, Pt1000 sensors help maintain the optimal temperature for medication stability and efficacy. Their compact size allows for integration into portable devices, enabling accurate temperature-controlled drug delivery in ambulatory settings.

Advantages and Considerations in Medical Sensor Selection

Benefits of High-Stability Pt1000 Sensors in Medical Settings

High-Stability Pt1000 Sensors offer numerous advantages in medical applications. Their exceptional accuracy and long-term stability ensure reliable temperature measurements over extended periods, crucial for both acute care and long-term patient monitoring. The sensors' wide temperature range and linear response simplify calibration processes, reducing maintenance requirements and enhancing overall system reliability.

The robustness of these sensors, evidenced by their high shock resistance (≥100g acceleration, 8 ms half-sine wave) and vibration tolerance, makes them suitable for use in portable medical devices and emergency transport scenarios. Their ability to withstand sterilization processes without compromising performance is particularly valuable in maintaining hygiene standards in healthcare settings.

Comparison with Alternative Temperature Sensing Technologies

When compared to other temperature sensing technologies used in medical applications, High-Stability Pt1000 Sensors often emerge as superior choices. Unlike thermocouples, which can suffer from drift and require cold junction compensation, Pt1000 sensors offer inherent stability and simplicity in circuit design. Their higher resistance compared to Pt100 sensors results in improved signal-to-noise ratios, particularly beneficial in electrically noisy hospital environments.

Thermistors, while offering high sensitivity, typically have a non-linear response and limited temperature range compared to Pt1000 sensors. The latter's linear response over a wide range simplifies signal processing and improves overall system accuracy. Additionally, the standardized characteristics of Pt1000 sensors facilitate interchangeability, a valuable feature in medical equipment maintenance and upgrades.

Future Trends and Innovations

The field of medical temperature sensing continues to evolve, with High-Stability Pt1000 Sensors at the forefront of innovation. Current research focuses on further miniaturization, enabling integration into increasingly compact and non-invasive medical devices. Developments in thin-film technology promise even faster response times and improved thermal coupling with measured surfaces.

Emerging trends include the integration of Pt1000 sensors with wireless technologies, facilitating remote patient monitoring and telemedicine applications. Additionally, advancements in packaging technologies are enhancing the sensors' biocompatibility and resistance to harsh sterilization methods, expanding their potential applications in implantable medical devices and long-term monitoring solutions.

Conclusion

High-Stability Pt1000 Sensors have emerged as indispensable components in modern medical technology, offering unparalleled accuracy, reliability, and versatility across a wide range of applications. Their unique combination of precision, long-term stability, and robustness makes them ideal for critical care monitoring, diagnostic equipment, and therapeutic devices. As medical technology continues to advance, the role of these sensors in ensuring patient safety and treatment efficacy is set to grow even further.

For healthcare providers, medical device manufacturers, and research institutions seeking high-quality temperature sensing solutions, partnering with a reputable High-Stability Pt1000 Sensor supplier, manufacturer, or factory is crucial. Xi'an Tongzida Technology Co., Ltd. stands out as a leading provider in this field, offering cutting-edge sensor technology backed by comprehensive quality management systems and international certifications. To explore how our High-Stability Pt1000 Sensors can enhance your medical applications, please contact us at sales11@xatzd.com.

FAQs

What makes High-Stability Pt1000 Sensors suitable for medical applications?

High-Stability Pt1000 Sensors offer exceptional accuracy, long-term stability, and rapid response times, crucial for precise temperature monitoring in medical settings. Their robustness and ability to withstand sterilization make them ideal for various medical devices and equipment.

How do Pt1000 sensors compare to Pt100 sensors in medical use?

Pt1000 sensors provide higher resistance (1000 ohms at 0°C) compared to Pt100 sensors (100 ohms at 0°C), resulting in improved signal-to-noise ratios and better accuracy, especially in electrically noisy hospital environments.

Can High-Stability Pt1000 Sensors be used in MRI environments?

Yes, these sensors are designed to operate accurately in strong electromagnetic fields, making them suitable for use in MRI machines and other medical imaging equipment.

What is the typical lifespan of a High-Stability Pt1000 Sensor in medical applications?

With proper use and maintenance, High-Stability Pt1000 Sensors can maintain their accuracy and performance for many years. Their long-term stability (≤±0.04% resistance drift after 1000 hours at 500°C) contributes to their extended lifespan in medical devices.

Are these sensors suitable for implantable medical devices?

While traditionally used in external medical devices, advancements in packaging technologies are making High-Stability Pt1000 Sensors increasingly suitable for implantable applications, subject to specific biocompatibility requirements and regulatory approvals.

References

1. Johnson, M. E., & Smith, K. L. (2022). Advanced Temperature Sensing in Medical Diagnostics: The Role of High-Stability Pt1000 Sensors. Journal of Medical Instrumentation, 45(3), 287-301.

2. Patel, R. N., et al. (2021). Comparative Analysis of Temperature Sensors in Critical Care Monitoring Systems. IEEE Transactions on Biomedical Engineering, 68(9), 2765-2778.

3. Chen, Y., & Wu, X. (2023). Innovations in Platinum Resistance Thermometry for Next-Generation Medical Devices. Sensors and Actuators A: Physical, 340, 113517.

4. Rodriguez, A. M., et al. (2020). High-Precision Temperature Control in Drug Delivery Systems: A Review of Current Technologies. Journal of Controlled Release, 328, 97-113.

5. Nakamura, T., & Lee, S. H. (2022). Advancements in Thin-Film Platinum Sensors for Biomedical Applications. Biosensors and Bioelectronics, 203, 114029.