Understanding the Technology Behind High Precision Thermistor Sensors

Thermistor Basics and Operating Principles

Thermistors are temperature-sensitive resistors that exhibit a change in electrical resistance as temperature fluctuates. High precision threaded thermistor temperature sensors leverage this property to provide accurate temperature measurements. These sensors typically utilize platinum resistor elements, such as Pt100, Pt500, or Pt1000, which offer excellent stability and linearity over a wide temperature range.

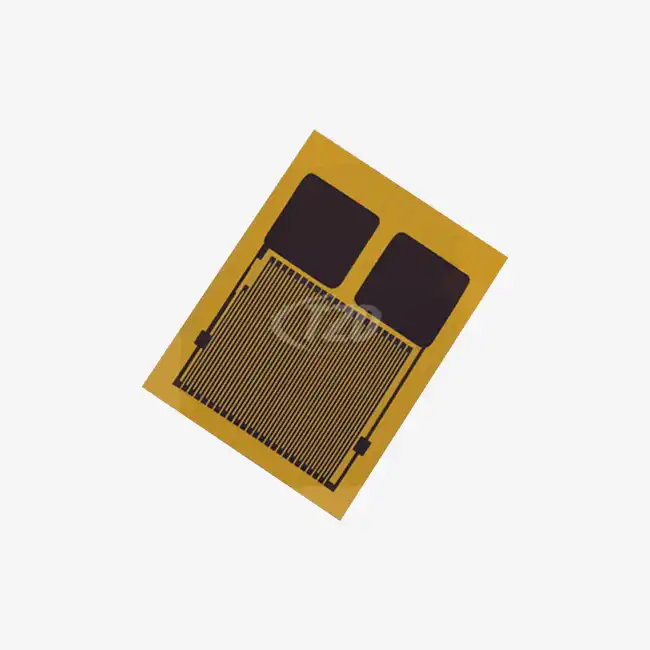

The core of a high precision thermistor sensor is its thin-film temperature-sensitive chip. This chip is designed, processed, and packaged using advanced technology to ensure optimal performance. The temperature coefficient of these sensors is usually 3850 ppm/K, which complies with the IEC60751 standard. This standardization ensures consistency and reliability across different sensor models and manufacturers.

Wire Configuration and Lead Wire Materials

High precision threaded thermistor temperature sensors come in various wire configurations, including two-wire, three-wire, and four-wire systems. The choice of configuration depends on the specific application requirements and the desired level of accuracy. Four-wire systems generally provide the highest precision by eliminating lead wire resistance effects.

The lead wire material also plays a crucial role in sensor performance. Common materials include FEP (Fluorinated Ethylene Propylene), Silicone Rubber, PTFE (Polytetrafluoroethylene), PVC (Polyvinyl Chloride), and Metal Braided High-Temperature Wire. Each material offers different properties in terms of temperature resistance, flexibility, and durability, allowing for customization based on the intended use environment.

Self-Heating and Insulation Considerations

One factor that can affect the accuracy of high precision thermistor sensors is self-heating. The self-heating coefficient, typically around 0.4 K/mW at 0°C, indicates how much the sensor's temperature rises due to the measurement current passing through it. To minimize this effect, these sensors often operate with low currents, ranging from 0.1 to 1 mA, depending on the sensor's nominal resistance.

Insulation resistance is another critical parameter for maintaining accuracy. High-quality sensors boast insulation resistance of ≥100 MΩ at 500 V DC and 20°C, ensuring minimal current leakage and reliable measurements even in challenging environments.

Factors Influencing the Accuracy of High Precision Thermistor Sensors

Accuracy Classes and Tolerances

High precision threaded thermistor temperature sensors are categorized into different accuracy classes, each with its specific tolerance range. These classes include:

- 1/30B Class: Tolerance ≤ ±0.01°C (0°C to +100°C)

- 1/10B Class: Tolerance ≤ ±0.03°C (0°C to +100°C)

- 1/3B Class: Tolerance ≤ ±0.10°C (0°C to +150°C)

- A Class: Tolerance ≤ ±0.15°C (-50°C to +300°C)

- B Class: Tolerance ≤ ±0.30°C (-70°C to +300°C)

The choice of accuracy class depends on the specific application requirements and the desired level of precision. Higher accuracy classes generally come at a premium but offer unparalleled measurement precision.

Temperature Range and Sensor Stability

The accuracy of high precision thermistor sensors can vary across different temperature ranges. While these sensors can cover a wide temperature span from -200°C to +850°C, their precision may be optimized for specific ranges. For instance, the highest accuracy is often achieved in the 0°C to 100°C range, which is crucial for many industrial and scientific applications.

Long-term stability is another critical factor in maintaining accuracy over time. High-quality sensors exhibit minimal drift, with some models achieving long-term stability drift ≤ 0.04%. This exceptional stability ensures reliable measurements over extended periods, reducing the need for frequent recalibration.

Environmental Factors and Sensor Robustness

The accuracy of high precision threaded thermistor temperature sensors can be influenced by various environmental factors. These sensors are designed to withstand challenging conditions, with features such as:

- Pressure Resistance: ≥0.5 MPa standard resistance

- Vibration Resistance: Up to 40g

- Impact Resistance: Up to 100g

These robust characteristics ensure that the sensors maintain their accuracy even in harsh industrial environments or applications subject to mechanical stress. Additionally, the choice of lead wire material and protective coatings can further enhance the sensor's resilience to environmental factors such as moisture, chemicals, and extreme temperatures.

Applications and Advancements in High Precision Thermistor Technology

Industry-Specific Applications

High precision threaded thermistor temperature sensors find applications across various industries due to their exceptional accuracy and reliability. Some key applications include:

- Industrial Process Control: Precise temperature monitoring in manufacturing processes, chemical reactions, and quality control.

- Medical Equipment: Accurate temperature measurement in diagnostic devices, incubators, and sterilization equipment.

- Automotive: Engine temperature monitoring, climate control systems, and battery management in electric vehicles.

- Aerospace: Critical temperature monitoring in aircraft systems and space exploration equipment.

- Scientific Research: High-precision temperature measurement in laboratory experiments and environmental studies.

The versatility of these sensors, combined with their high accuracy, makes them indispensable in scenarios where even slight temperature variations can have significant consequences.

Technological Advancements and Future Trends

The field of high precision thermistor technology is continuously evolving, with ongoing advancements aimed at improving accuracy, reliability, and functionality. Some notable trends include:

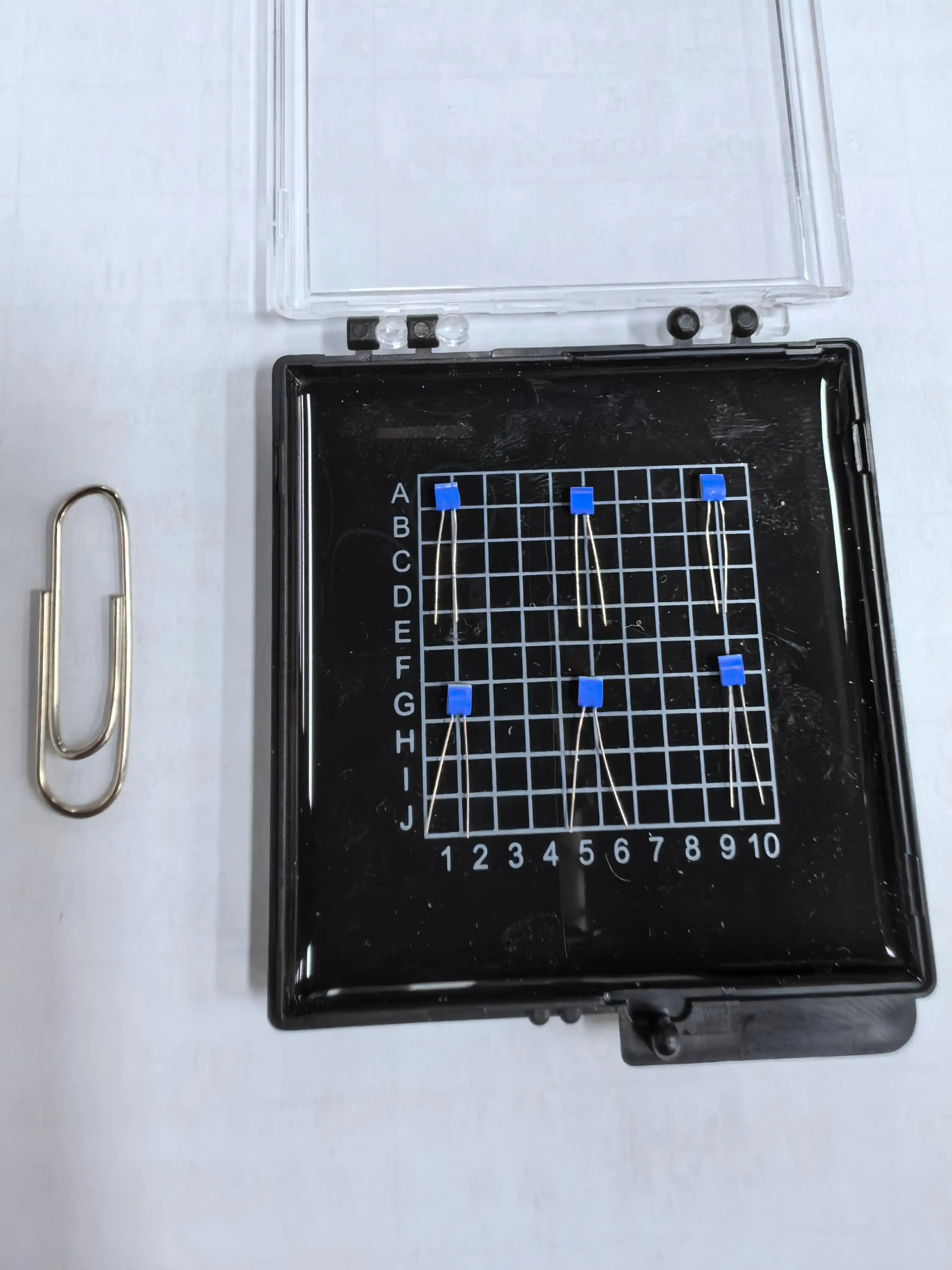

- Miniaturization: Development of smaller sensors (ranging from 1.2mm to 4.0mm) without compromising accuracy, enabling integration into compact devices.

- Multi-sensor Integration: Combining temperature sensing with other parameters like pressure or humidity for comprehensive environmental monitoring.

- Smart Sensors: Integration of digital interfaces and onboard processing capabilities for easier integration with IoT systems and real-time data analysis.

- Advanced Materials: Research into novel materials for sensor elements and coatings to enhance stability, response time, and temperature range.

- Customization Options: Tailored solutions with various lead materials (platinum nickel, silver nickel, pure platinum) and configurations to meet specific industry needs.

These advancements are pushing the boundaries of what's possible in temperature measurement, opening up new applications and improving existing processes across industries.

Calibration and Maintenance for Optimal Performance

To maintain the high accuracy of threaded thermistor temperature sensors, proper calibration and maintenance are essential. Regular calibration ensures that the sensor's output remains aligned with standard temperature references. The calibration process typically involves comparing the sensor's readings to those of a highly accurate reference thermometer across its operating range.

Maintenance practices include:

- Periodic inspection for physical damage or contamination

- Proper cleaning using manufacturer-recommended methods

- Protection from extreme environmental conditions when not in use

- Regular performance checks to detect any drift in accuracy

- Replacement of sensors that show signs of degradation or have exceeded their recommended lifespan

By following these practices, users can ensure that their high precision thermistor sensors continue to deliver accurate and reliable temperature measurements over time.

Conclusion

High precision threaded thermistor temperature sensors represent the pinnacle of temperature measurement technology, offering unparalleled accuracy and reliability across a wide range of applications. Their ability to provide precise measurements, coupled with their robustness and adaptability, makes them invaluable tools in industries ranging from healthcare to aerospace. As technology continues to advance, we can expect even greater precision and functionality from these sensors, further expanding their utility in both existing and emerging fields.

For those seeking cutting-edge temperature measurement solutions, high precision thermistor sensors offer a compelling combination of accuracy, reliability, and versatility. Whether you're involved in critical industrial processes, scientific research, or developing next-generation technologies, these sensors provide the precision and dependability needed to drive innovation and ensure optimal performance. To explore how high precision threaded thermistor temperature sensors can benefit your specific application or to learn more about the latest advancements in sensor technology, please contact us at sales11@xatzd.com.