Grasping Resistance Temperature Sensors and Their Types

Resistance temperature sensors, also known as Resistance Temperature Detectors (RTDs), are temperature-sensing devices that operate on the principle of change in electrical resistance with temperature. The most common types of RTDs are Pt100, Pt500, and Pt1000, named after their nominal resistance at 0°C.

Pt100, Pt500, and Pt1000: Key Differences

Pt100 RTDs have a resistance of 100 ohms at 0°C, while Pt500 and Pt1000 have 500 ohms and 1000 ohms, respectively. The higher resistance of Pt500 and Pt1000 sensors offers improved sensitivity and reduced impact of lead wire resistance, making them suitable for applications requiring higher accuracy or longer cable runs.

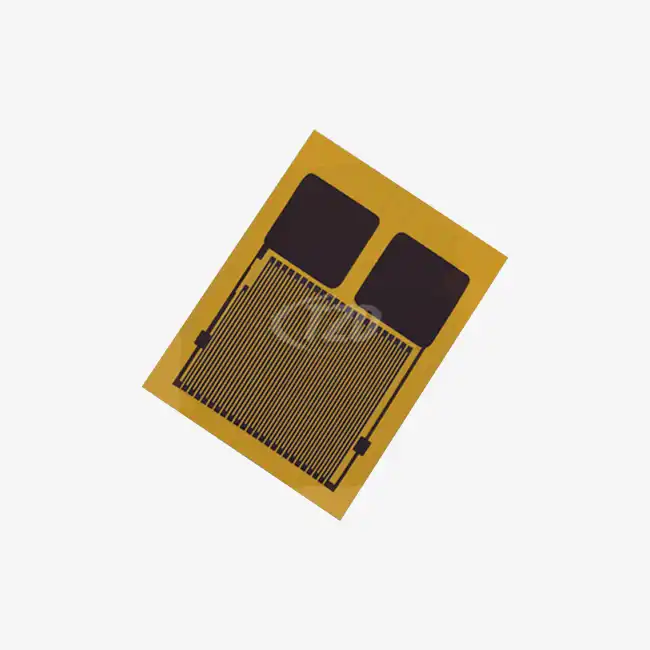

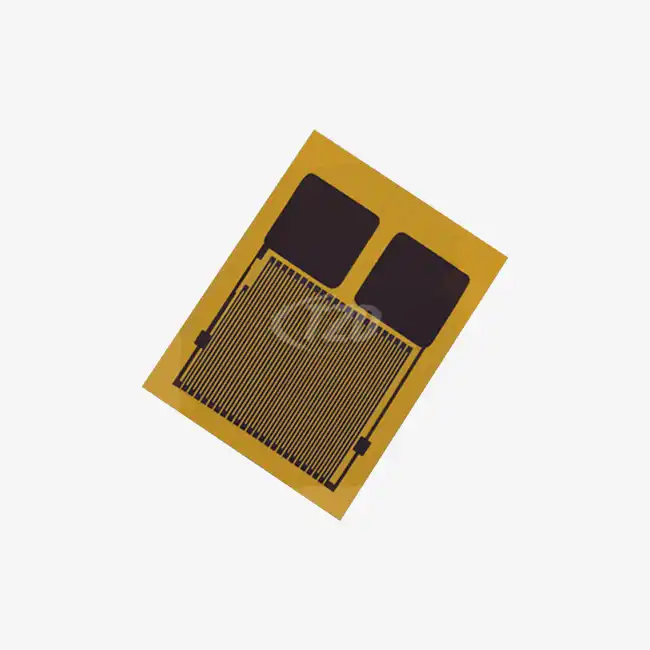

Screw Type Thermal Resistance Temperature Sensor: A Closer Look

Screw type thermal resistance temperature sensors are a specific variant of RTDs designed for easy installation and reliable performance in various industrial applications. These sensors feature a threaded body that allows for secure mounting in pipes, tanks, or other process equipment. The screw-in design ensures excellent thermal contact with the measured medium, contributing to improved accuracy and faster response times.

Factors Affecting Resistance Temperature Sensor Accuracy

Several factors influence the accuracy of resistance temperature sensors, including temperature range, wire configuration, and lead wire materials. Understanding these factors is crucial for selecting the right sensor and ensuring optimal performance in your application.

Temperature Ranges and Their Impact on Accuracy

Resistance temperature sensors (RTDs) are available in a variety of temperature ranges to accommodate diverse industrial needs. Standard RTDs typically operate from -70°C to +300°C, making them suitable for most industrial environments. For more demanding applications, such as cryogenic or high-temperature processes, specialized sensors can function across a wider range, from -200°C to +850°C. It's important to note that sensor accuracy often varies across this range, with optimal precision generally observed at mid-range temperatures.

Wire Configuration: Two-Wire, Three-Wire, and Four-Wire Systems

The wire configuration in an RTD plays a crucial role in determining measurement accuracy, especially in screw type thermal resistance temperature sensors commonly used in industrial equipment. Two-wire systems are the most basic and cost-effective but suffer from reduced accuracy due to lead wire resistance—an issue that worsens with long cable runs. Three-wire configurations improve accuracy by compensating for lead resistance. Four-wire systems offer the highest precision, making them ideal for critical applications requiring accurate and stable readings, such as in screw-mounted sensors installed in reactors, pipelines, or HVAC systems.

Lead Wire Materials and Their Effect on Measurement Accuracy

The material used for lead wires in RTD systems can significantly influence the accuracy and durability of temperature measurements, especially in harsh environments. Common materials include FEP, Silicone Rubber, PTFE, and PVC, each offering different benefits in terms of thermal stability, chemical resistance, and flexibility. In high-temperature settings, metal-braided wires are often utilized to enhance protection and performance. Choosing the appropriate lead wire material requires careful consideration of environmental conditions, mechanical stress, and the operating temperature range of the application.

Accuracy Classes and Performance Specifications

Screw type thermal resistance temperature sensors are classified into different accuracy classes based on their tolerance levels. Understanding these classes and other performance specifications is crucial for selecting the right sensor for your application.

Accuracy Classes: 1/3B, A, and B

The IEC 60751 standard categorizes platinum resistance thermometers into several accuracy classes to help users select sensors suited to their precision needs. Class 1/3B offers the highest precision, with a tolerance of ±0.10°C between 0°C and +150°C. Class A has a broader operating range with a tolerance of ±0.15°C from -50°C to +300°C, while Class B allows ±0.30°C from -70°C to +300°C. Selection depends on your application's required accuracy and typical operating temperature conditions.

Temperature Coefficient and Self-Heating Effects

The temperature coefficient of an RTD defines how its resistance changes with temperature, directly influencing measurement sensitivity. Platinum RTDs generally follow a standardized coefficient of 3850 ppm/K, meaning the resistance increases by 0.385Ω per degree Celsius for a 100Ω sensor. However, the self-heating effect—caused by the measuring current—can introduce error, especially in still air or poor heat dissipation environments. Typically around 0.4 K/mW at 0°C, this effect must be minimized by optimizing current levels and ensuring good thermal contact.

Operating Current and Insulation Resistance

The operating current applied to RTDs must be carefully selected based on the sensor's resistance to ensure accurate temperature readings without inducing self-heating. For standard 100Ω RTDs, the recommended current ranges from 0.3 to 1 mA. Higher-resistance RTDs require proportionally lower currents: 500Ω sensors typically operate between 0.1 and 0.7 mA, while 1000Ω sensors should be limited to 0.1 to 0.3 mA. Exceeding these limits can lead to sensor heating, resulting in measurement inaccuracies and long-term sensor degradation. Insulation resistance, typically ≥100 MΩ @ 500 V DC & 20°C, is another important specification that ensures electrical isolation and measurement accuracy.

Conclusion

Understanding the various factors affecting resistance temperature sensor accuracy is crucial for selecting the right sensor for your application. Screw type thermal resistance temperature sensors offer a convenient and reliable solution for many industrial temperature measurement needs. By considering the RTD type, temperature range, wire configuration, and accuracy class, you can ensure optimal performance and reliability in your temperature measurement applications.

For more information about our high-quality resistance temperature sensors, including screw type thermal resistance temperature sensors, please contact us at sales11@xatzd.com. Our team of experts is ready to help you find the perfect solution for your temperature measurement needs.