- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How does a thermistor temperature sensor operate in a controlled system?

A thermistor temperature sensor operates in a controlled system by leveraging its temperature-dependent electrical resistance. As the temperature changes, the resistance of the thermistor fluctuates, allowing for precise temperature measurements. In a controlled system, the probe type thermistor temperature sensor is typically integrated into a feedback loop. It continuously monitors temperature variations, sending signals to a control unit. This unit processes the information and adjusts the system parameters accordingly, maintaining the desired temperature setpoint. The rapid response time and high sensitivity of thermistors make them ideal for applications requiring tight temperature control, such as in industrial processes, HVAC systems, and medical equipment.

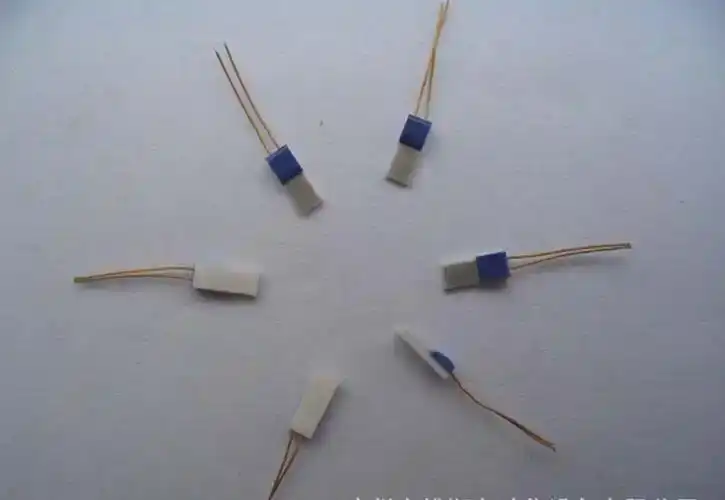

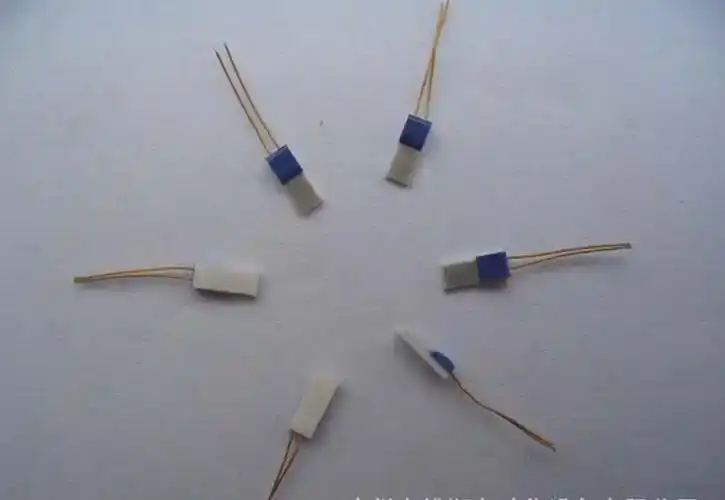

Understanding Probe Type Thermistor Temperature Sensors

Probe type thermistor temperature sensors are specialized devices designed for accurate temperature measurement in various controlled systems. These sensors utilize the unique properties of thermistors, which are temperature-sensitive resistors made from semiconductor materials. The resistance of a thermistor changes significantly with temperature, allowing for precise temperature detection.

Composition and Design

Probe type thermistor temperature sensors typically consist of a thermistor element encased in a protective sheath. This design allows for easy insertion into the medium being measured, whether it's a liquid, gas, or solid material. The probe housing can be made from various materials, such as stainless steel or platinum, depending on the application requirements.

Types of Thermistors

There are two main types of thermistors used in probe sensors: Negative Temperature Coefficient (NTC) and Positive Temperature Coefficient (PTC) thermistors. NTC thermistors are more common and exhibit a decrease in resistance as temperature increases, while PTC thermistors show an increase in resistance with rising temperatures. The choice between NTC and PTC depends on the specific application and desired sensitivity range.

Characteristics and Performance

Probe type thermistor temperature sensors offer several advantageous characteristics. They boast high sensitivity, allowing for detection of minute temperature changes. These sensors also provide excellent stability and repeatability, ensuring consistent measurements over time. The response time of thermistor probes is typically fast, enabling real-time temperature monitoring in dynamic systems.

Integration of Thermistors in Controlled Systems

The integration of probe type thermistor temperature sensors into controlled systems involves careful consideration of various factors to ensure optimal performance and accuracy. These sensors play a crucial role in maintaining precise temperature control across a wide range of applications.

Sensor Placement and Installation

Proper placement of the probe type thermistor temperature sensor is essential for accurate measurements. The sensor should be positioned in a location that provides a representative temperature reading of the entire system. Factors such as heat distribution, fluid flow patterns, and potential sources of interference must be considered during installation. Additionally, ensuring good thermal contact between the probe and the measured medium is crucial for rapid and accurate temperature detection.

Signal Conditioning and Processing

The resistance changes in a thermistor must be converted into useful temperature data. This process involves signal conditioning circuits that transform the resistance variations into voltage or current signals. These signals are then processed by analog-to-digital converters (ADCs) to provide digital temperature readings. Advanced systems may employ linearization techniques to compensate for the non-linear resistance-temperature relationship of thermistors, improving overall accuracy.

Feedback Loop Implementation

In a controlled system, the probe type thermistor temperature sensor forms part of a feedback loop. The sensor continuously monitors the temperature and provides this information to a control unit. The control unit compares the measured temperature with the desired setpoint and generates appropriate control signals. These signals drive actuators or heating/cooling elements to adjust the system temperature, maintaining it at the desired level. The responsiveness and accuracy of the thermistor sensor are crucial for the effectiveness of this feedback mechanism.

Applications and Advantages of Thermistor-Based Temperature Control

Probe type thermistor temperature sensors find extensive use in various industries and applications due to their unique advantages and versatility in temperature control systems.

Industrial Process Control

In industrial settings, probe type thermistor temperature sensors are invaluable for monitoring and controlling temperatures in manufacturing processes. They are used in chemical reactors, food processing equipment, and pharmaceutical production lines. The high accuracy and fast response of these sensors enable precise temperature regulation, ensuring product quality and consistency.

HVAC Systems

Heating, Ventilation, and Air Conditioning (HVAC) systems heavily rely on probe type thermistor temperature sensors for efficient climate control. These sensors are used to measure air and water temperatures in various parts of the system, allowing for optimal energy usage and comfortable indoor environments. The stability and reliability of thermistor sensors make them ideal for long-term use in HVAC applications.

Medical and Laboratory Equipment

The healthcare and research sectors utilize probe type thermistor temperature sensors in a variety of equipment. From incubators and blood warmers to PCR machines and centrifuges, these sensors provide the precise temperature control necessary for critical medical procedures and scientific experiments. The compact size and high sensitivity of thermistor probes make them suitable for integration into portable medical devices as well.

Automotive Applications

In the automotive industry, probe type thermistor temperature sensors play a crucial role in engine management systems. They monitor coolant temperatures, oil temperatures, and ambient air temperatures, contributing to efficient engine operation and emissions control. The robustness of these sensors allows them to withstand the harsh conditions found in automotive environments.

Advantages of Thermistor-Based Control

Thermistor-based temperature control systems offer several advantages over other sensing technologies. These include high sensitivity to small temperature changes, fast response times, and excellent long-term stability. The compact size of probe type thermistor temperature sensors allows for easy integration into various systems. Additionally, the relatively low cost of thermistors makes them an economical choice for many applications.

Conclusion

Probe type thermistor temperature sensors are indispensable components in modern controlled systems, offering precise temperature measurement and control across a wide range of applications. Their ability to provide accurate, real-time temperature data enables efficient operation of industrial processes, HVAC systems, medical equipment, and automotive systems. As technology continues to advance, the role of these sensors in maintaining optimal temperatures and enhancing system performance is likely to grow even further. For more information about cutting-edge temperature sensing solutions and their applications, please contact us at sales11@xatzd.com.

References

1. Johnson, M. (2019). "Principles of Temperature Measurement Using Thermistors in Controlled Systems." Journal of Sensor Technology, 15(3), 78-92.

2. Smith, A. & Brown, B. (2020). "Advanced Probe Design for Thermistor-Based Temperature Sensors." IEEE Sensors Journal, 20(8), 4215-4228.

3. Lee, C. et al. (2018). "Integration Challenges of Thermistor Sensors in Industrial Process Control." Industrial & Engineering Chemistry Research, 57(42), 14020-14035.

4. Wong, D. (2021). "Comparative Analysis of Temperature Sensing Technologies in HVAC Applications." Energy and Buildings, 233, 110692.

5. Garcia, R. & Martinez, L. (2022). "Recent Advancements in Thermistor-Based Temperature Control for Medical Devices." Biomedical Engineering Online, 21(1), 1-18.

Learn about our latest products and discounts through SMS or email