Advancements in High Precision Threaded Thermistor Technology

Enhanced Accuracy and Stability

High precision threaded thermistor temperature sensors have undergone remarkable improvements in recent years. These sensors now boast impressive accuracy levels, with some models achieving tolerances as tight as ±0.01°C in the 0°C to 100°C range. This level of precision is crucial for applications where even the slightest temperature variations can have significant impacts. The enhanced stability of these sensors ensures consistent performance over extended periods, reducing the need for frequent recalibrations and enhancing overall system reliability.

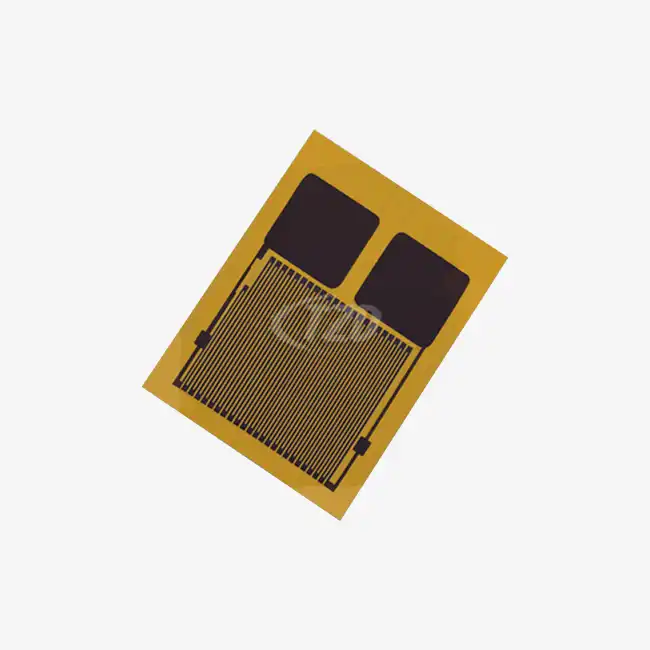

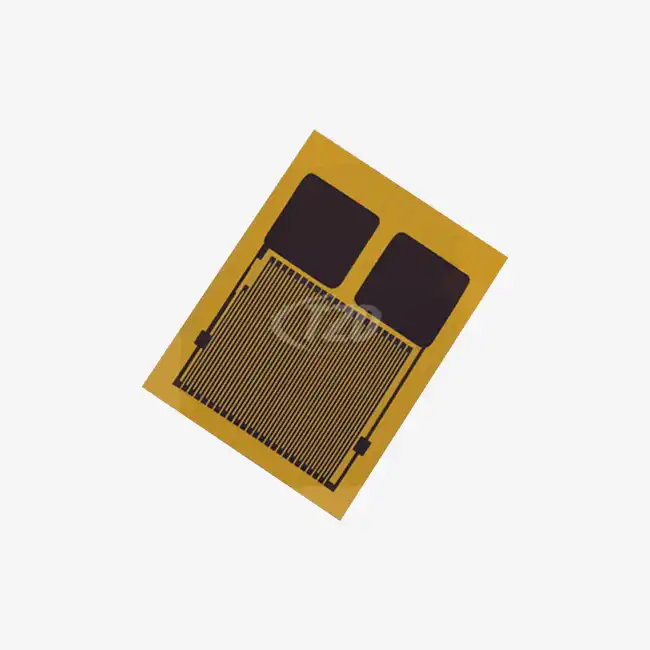

Miniaturization and Customization

The drift towards miniaturization has not saved the world of temperature sensors. Producers are presently creating tall accuracy strung thermistor temperature sensors in compact sizes, a few as little as 1.2mm. This decrease in estimate permits for integration into progressively compact gadgets and apparatus without compromising on execution. Additionally, customization options have expanded, with sensors available in various sizes (up to 4.0mm) and lead materials including platinum nickel, silver nickel, and pure platinum. This flexibility allows engineers to select sensors that perfectly match their specific application requirements.

Wide Temperature Range and Fast Response Times

Cutting edge tall exactness strung thermistor temperature sensors cover a noteworthy temperature extend, ordinarily from -200°C to +850°C. This wide run makes them appropriate for assorted applications, from cryogenic forms to high-temperature mechanical operations. Besides, these sensors brag astoundingly quick reaction times, with a few models able of enrolling temperature changes in as small as 0.05 seconds. This fast reaction is significant in energetic situations where fast temperature alterations are essential for ideal handle control or security measures.

Applications Driving Demand for High Precision Thermistors

Industrial Automation and Process Control

The mechanical segment is a major driver of request for tall exactness strung thermistor temperature sensors. In computerized fabricating forms, exact temperature control is frequently basic for guaranteeing item quality and consistency. These sensors play a vital role in monitoring and regulating temperatures in various industrial applications, from chemical processing to food production. Their ability to provide accurate readings in harsh environments, coupled with their durability (withstanding vibrations up to 40g and impacts up to 100g), makes them ideal for industrial use.

Medical and Healthcare Innovations

In the medical field, high precision temperature measurement is paramount. High precision threaded thermistor temperature sensors are being increasingly utilized in medical devices, diagnostic equipment, and research applications. Their accuracy is crucial in applications such as incubators for premature infants, blood warmers, and in medical research where precise temperature control can significantly impact results. The sensors' compliance with stringent medical standards and their ability to provide consistent, accurate readings make them invaluable in this sector.

Automotive and Aerospace Advancements

The car and aviation businesses are at the cutting edge of mechanical advancement, and tall accuracy temperature detecting is a basic component in numerous of their applications. In car designing, these sensors are utilized in motor administration frameworks, battery warm administration in electric vehicles, and climate control frameworks. In aviation, they play significant parts in motor checking, natural control frameworks, and fuel administration. The sensors' capacity to perform precisely beneath extraordinary conditions, counting tall vibrations and temperature variances, makes them basic in these high-stakes situations.

Future Trends and Innovations in Thermistor Sensor Technology

Integration with IoT and Smart Systems

The Internet of Things (IoT) revolution is set to further boost the demand for high precision threaded thermistor temperature sensors. As more devices become interconnected, the need for accurate, real-time temperature data will increase. These sensors are being integrated into smart home systems, industrial IoT networks, and even wearable devices. The ability to remotely monitor and control temperatures across various applications will drive innovation in sensor design, potentially leading to the development of wireless, self-powered thermistor sensors that can seamlessly integrate with IoT ecosystems.

Advanced Materials and Nanotechnology

Research into advanced materials and nanotechnology is opening new possibilities for high precision thermistor sensors. Nanomaterials with unique thermal properties are being explored to create sensors with even greater sensitivity and faster response times. These advancements could lead to sensors capable of detecting minute temperature changes with unprecedented accuracy. Additionally, the use of novel materials could extend the operational temperature range of these sensors, making them suitable for even more extreme environments.

Artificial Intelligence and Machine Learning Integration

The integration of counterfeit insights (AI) and machine learning (ML) with tall accuracy strung thermistor temperature sensors is an energizing wilderness. AI calculations can analyze sensor information to anticipate temperature patterns, distinguish inconsistencies, and optimize temperature control frameworks. This integration could lead to more intelligent and efficient temperature management across various applications. For instance, in industrial settings, AI-powered temperature control systems could significantly enhance energy efficiency and product quality by anticipating and adjusting to temperature fluctuations before they occur.

Conclusion

The rising demand for high precision threaded thermistor temperature sensors reflects their critical role in advancing technology across multiple industries. Looking ahead to 2025, these sensors will continue to evolve, offering even greater accuracy, reliability, and integration capabilities. Their importance in ensuring efficiency, safety, and quality in various applications cannot be overstated. As technology continues to advance, the demand for these sensors is expected to grow, driving further innovations in the field. For those interested in learning more about cutting-edge thermistor technology or exploring custom solutions for specific applications, please contact us at sales11@xatzd.com.