- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How to Diagnose and Prevent Pt1000 Sensor Stability Issues?

Diagnosing and preventing stability issues in high-stability Pt1000 sensors involves a multi-faceted approach. Regular calibration checks, proper installation techniques, and environmental control are crucial. Monitor sensor output for drift or inconsistencies, ensure correct wiring and shielding, and protect against temperature extremes, vibration, and contamination. Implement data logging and trend analysis to detect gradual changes. Choose sensors with superior long-term stability specifications, such as those with ≤±0.04% resistance drift after 1000 hours at 500°C. By combining these strategies, you can significantly enhance the reliability and longevity of your Pt1000 sensor measurements.

Grasping High-Stability Pt1000 Sensor Characteristics

High-Stability Pt1000 Sensors are precision instruments designed for accurate temperature measurement across a wide range. These platinum resistance thermometers offer exceptional stability and reliability, making them ideal for demanding applications in industries such as aerospace, medical, and industrial process control.

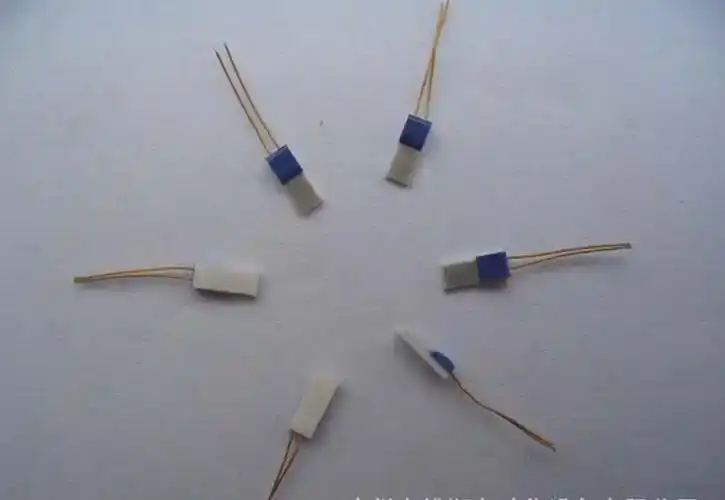

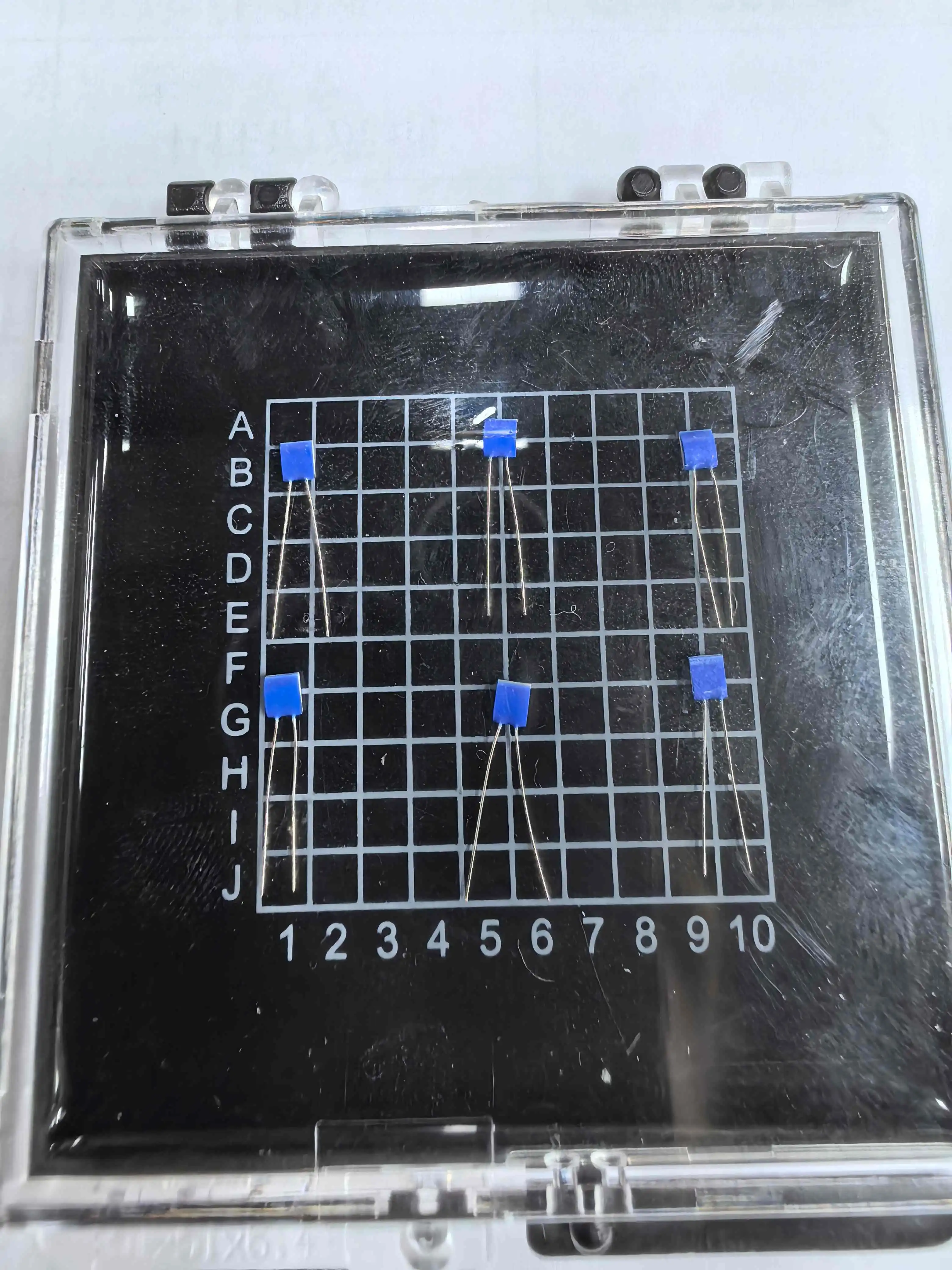

The core of a High-Stability Pt1000 Sensor is a platinum resistive element with a nominal resistance of 1000 ohms at 0°C. This element is typically manufactured using thin-film technology, allowing for compact dimensions such as 2.0mm x 2.3mm x 1.0mm or 2.0mm x 4.0mm x 1.0mm. The sensor's temperature coefficient (TCR) of 3850 ppm/°C ensures a linear and predictable response to temperature changes.

One of the standout features of these sensors is their remarkable long-term stability. High-quality Pt1000 sensors can maintain a resistance drift of ≤±0.04% of R₀ (0°C reference) after 1000 hours at 500°C. This stability is crucial for applications requiring consistent accuracy over extended periods.

Key Performance Metrics

Several performance metrics define the capabilities of high-stability Pt1000 sensors:

- Operating Current: Typically 0.1–0.3 mA, with consideration for self-heating effects

- Insulation Resistance: 100 MΩ at 20°C, maintaining >2 MΩ at 500°C

- Response Time: In water flow (V=0.4 m/s), t₀.₅ = 0.05 s, t₀.₉ = 0.15 s; In airflow (V=2 m/s), t₀.₅ = 3 s, t₀.₉ = 10 s

- Self-Heating Coefficient: 0.4°C/mW at 0°C

- Vibration Resistance: ≥40g acceleration (10–2000 Hz frequency range)

- Shock Resistance: ≥100g acceleration (8 ms half-sine wave)

These specifications underscore the sensor's ability to provide accurate readings in dynamic and challenging environments. The combination of rapid response times and high resistance to mechanical stresses makes High-Stability Pt1000 Sensors suitable for applications ranging from precise laboratory measurements to rugged industrial processes.

Common Stability Issues and Diagnostic Techniques

Despite their robust design, High-Stability Pt1000 Sensors can encounter stability issues that affect their performance. Recognizing these problems early is key to maintaining measurement accuracy and reliability. Here are some common stability issues and techniques to diagnose them:

Drift and Calibration Shifts

Drift refers to gradual changes in the sensor's output over time, even when measuring a constant temperature. This can be caused by physical changes in the platinum element or contamination.

Diagnostic Techniques:

- Regular calibration checks against a known reference

- Implementing a data logging system to track long-term trends

- Comparing sensor readings with redundant sensors in the same environment

Mechanical Stress and Vibration Effects

While high-stability Pt1000 sensors are designed to withstand significant mechanical stress, extreme conditions can lead to stability issues.

Diagnostic Techniques:

- Visual inspection for signs of physical damage or deformation

- Monitoring sensor output during known vibration events

- Performing periodic shock and vibration tests within specified limits (≥40g for vibration, ≥100g for shock)

Thermal Cycling and Hysteresis

Repeated exposure to temperature extremes can cause hysteresis, where the sensor's resistance at a given temperature depends on its recent thermal history.

Diagnostic Techniques:

- Conducting controlled thermal cycling tests and analyzing hysteresis curves

- Comparing sensor readings during heating and cooling cycles

- Implementing temperature stabilization periods before critical measurements

Electrical Interference and Noise

External electrical fields or improper wiring can introduce noise and instability in sensor readings.

Diagnostic Techniques:

- Using shielded cables and proper grounding techniques

- Employing noise rejection algorithms in the data acquisition system

- Conducting EMI/RFI susceptibility tests in the operating environment

By systematically applying these diagnostic techniques, engineers and technicians can identify stability issues in High-Stability Pt1000 Sensors before they significantly impact measurement accuracy. Early detection allows for timely corrective actions, ensuring the continued reliability of temperature-critical processes and experiments.

Preventive Measures and Best Practices

Maintaining the stability and accuracy of high-stability Pt1000 sensors requires a proactive approach. By implementing preventive measures and adhering to best practices, you can significantly extend the sensor's lifespan and ensure consistent performance. Here are key strategies to prevent stability issues:

Environmental Control and Protection

Creating an optimal operating environment is crucial for sensor stability:

- Temperature Management: Ensure the sensor operates within its specified temperature range (-200°C to +850°C for many Pt1000 sensors).

- Humidity Control: Use hermetically sealed sensors or implement desiccant systems in humid environments.

- Vibration Isolation: Employ shock-absorbing mounts to mitigate mechanical stress, especially in applications approaching the 40g vibration resistance limit.

- Chemical Protection: Use appropriate protective coatings or sheaths to prevent chemical contamination of the sensor element.

Proper Installation and Wiring Practices

Correct installation is fundamental to sensor stability:

- Lead Wire Management: Use appropriate lead materials (e.g., platinum-nickel, silver-palladium, or pure silver) and ensure proper wire length (typically 10 mm) to minimize thermal conduction errors.

- Strain Relief: Implement strain relief mechanisms to protect the sensor leads, which should withstand ≥9 N of tensile strength.

- Electrical Connections: Use high-quality, low-resistance connections and consider four-wire configurations for improved accuracy.

- Shielding: Employ proper shielding techniques to maintain the sensor's high insulation resistance (100 MΩ at 20°C, >2 MΩ at 500°C).

Calibration and Maintenance Schedule

Regular calibration and maintenance are essential for long-term stability:

- Periodic Calibration: Establish a calibration schedule based on the application's accuracy requirements and the sensor's drift characteristics (≤±0.04% resistance drift after 1000 hours at 500°C for high-stability sensors).

- In-situ Verification: Implement methods for in-situ verification of sensor performance without disrupting processes.

- Cleaning and Inspection: Regularly inspect and clean sensors to prevent contamination-induced drift.

- Documentation: Maintain detailed records of calibration history, environmental conditions, and any observed anomalies.

Advanced Signal Processing and Data Analysis

Leverage modern technology to enhance sensor stability:

- Digital Filtering: Implement advanced filtering algorithms to reduce noise while maintaining the sensor's fast response time (t₀.₅ = 0.05 s in water flow).

- Intelligent Alarming: Develop smart alarming systems that can differentiate between genuine temperature changes and sensor instability.

- Predictive Maintenance: Utilize machine learning algorithms to predict sensor drift and schedule preemptive maintenance.

- Multi-sensor Fusion: Combine data from multiple sensors to improve overall measurement stability and reliability.

By integrating these preventive measures and best practices, you can optimize the performance of High-Stability Pt1000 Sensors in your applications. This proactive approach not only ensures measurement accuracy but also contributes to the overall reliability and efficiency of your temperature-dependent processes.

Conclusion

High-stability Pt1000 sensors are invaluable tools in precision temperature measurement, offering remarkable accuracy and long-term stability. By understanding their characteristics, recognizing potential stability issues, and implementing robust preventive measures, engineers and technicians can maximize the performance and longevity of these sensors. Regular diagnostics, proper installation, and adherence to best practices are key to maintaining the ≤±0.04% resistance drift specification and ensuring reliable operation across diverse applications.

As temperature measurement continues to play a critical role in various industries, the importance of maintaining sensor stability cannot be overstated. For more information on high-stability temperature sensing solutions and expert guidance, please contact us at sales11@xatzd.com.

References

1. McGee, T. D. (2018). Principles and Methods of Temperature Measurement. John Wiley & Sons.

2. Childs, P. R. N. (2019). Practical Temperature Measurement. Butterworth-Heinemann.

3. Baker, B. C. (2017). Temperature Sensing Technologies. Microchip Technology Inc.

4. Wang, X., & Liu, J. (2020). Advanced Platinum Resistance Temperature Detectors: Design, Calibration, and Applications. Sensors, 20(18), 5108.

5. Michalski, L., Eckersdorf, K., Kucharski, J., & McGhee, J. (2001). Temperature Measurement. John Wiley & Sons.

Learn about our latest products and discounts through SMS or email