- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How High-Stability Pt1000 Sensors Improve Industrial Oven Performance?

High-Stability Pt1000 Sensors significantly enhance industrial oven performance by providing precise and reliable temperature measurements. These advanced sensors, with their exceptional long-term stability and accuracy, enable tight temperature control in industrial ovens. By minimizing temperature fluctuations and ensuring consistent heat distribution, High-Stability Pt1000 Sensors contribute to improved product quality, reduced energy consumption, and increased process efficiency. Their ability to withstand harsh environments and maintain accuracy over extended periods makes them invaluable for optimizing industrial oven operations across various industries.

Understanding High-Stability Pt1000 Sensors and Their Role in Industrial Ovens

The Fundamentals of Pt1000 Sensors

Pt1000 sensors are platinum resistance thermometers (PRTs) that operate on the principle of temperature-dependent electrical resistance. The "1000" in Pt1000 refers to the sensor's resistance of 1000 ohms at 0°C. These sensors are renowned for their linearity, accuracy, and stability over a wide temperature range.

High-Stability Pt1000 Sensors take these qualities to the next level. With a temperature coefficient (TCR) of 3850 ppm/°C, they offer exceptional sensitivity to temperature changes. This characteristic makes them ideal for applications requiring precise temperature control, such as industrial ovens.

Key Features of High-Stability Pt1000 Sensors

Several features set High-Stability Pt1000 Sensors apart from standard temperature sensors:

- Long-Term Stability: These sensors exhibit a resistance drift of ≤±0.04% of R₀ (0°C reference) after 1000 hours at 500°C, ensuring reliable measurements over extended periods.

- Wide Temperature Range: They can operate effectively from -200°C to +850°C, covering the temperature spectrum of most industrial ovens.

- Rapid Response: With response times as low as t₀.₅ = 0.05 s in water flow, these sensors quickly detect temperature changes, enabling prompt adjustments in oven control systems.

- Vibration and Shock Resistance: Capable of withstanding ≥40g acceleration in vibration and ≥100g in shock, they maintain accuracy in demanding industrial environments.

The Importance of Temperature Control in Industrial Ovens

Precise temperature control is crucial in industrial ovens for several reasons:

- Product Quality: Consistent temperatures ensure uniform processing and product quality.

- Energy Efficiency: Accurate control prevents energy waste from overheating or unnecessary temperature fluctuations.

- Process Optimization: Stable temperatures allow for fine-tuning of processes, improving overall efficiency.

- Regulatory Compliance: Many industries have strict temperature control requirements that must be met.

High-Stability Pt1000 Sensors address these needs by providing the accuracy and reliability necessary for maintaining optimal oven performance.

Enhancing Industrial Oven Performance with High-Stability Pt1000 Sensors

Precision Temperature Measurement and Control

The exceptional accuracy of High-Stability Pt1000 Sensors, with their ±0.01 Ω precision, translates to tighter temperature control in industrial ovens. This level of precision allows for:

- Finer temperature adjustments, crucial for processes sensitive to small temperature variations.

- Reduction in temperature overshoots and undershoots, leading to more stable oven conditions.

- Improved repeatability of thermal processes, ensuring consistent product quality across batches.

By leveraging the sensor's high TCR of 3850 ppm/°C, oven control systems can detect and respond to minute temperature changes swiftly and accurately.

Enhanced Thermal Uniformity

Industrial ovens often struggle with temperature gradients that can lead to uneven processing. High-Stability Pt1000 Sensors help mitigate this issue by:

- Enabling multi-point temperature monitoring within the oven, identifying and addressing hot or cold spots.

- Facilitating more sophisticated control algorithms that can adjust heating elements individually to maintain uniform temperatures.

- Providing data for thermal mapping and validation of oven performance, crucial for industries with stringent quality requirements.

Improved Energy Efficiency

The precision offered by High-Stability Pt1000 Sensors contributes significantly to energy efficiency in industrial ovens:

- Accurate temperature readings prevent unnecessary heating or cooling cycles, reducing energy waste.

- Faster response times (t₀.₅ = 3 s in airflow) allow for quicker adjustments, minimizing energy-intensive temperature corrections.

- Long-term stability ensures that energy efficiency is maintained over time, without drift-induced overcorrections.

These improvements can lead to substantial energy savings, particularly in high-volume or continuous operation scenarios.

Durability and Reliability in Harsh Environments

Industrial ovens often operate in challenging conditions. High-Stability Pt1000 Sensors are engineered to thrive in these environments:

- High temperature resistance up to 850°C ensures accuracy even in extreme heat.

- Vibration resistance of ≥40g and shock resistance of ≥100g maintain sensor integrity in dynamic industrial settings.

- Insulation resistance of 100 MΩ at 20°C and >2 MΩ at 500°C prevents electrical interference and ensures reliable readings.

This robustness translates to reduced downtime, lower maintenance costs, and more consistent oven performance over time.

Implementing High-Stability Pt1000 Sensors for Optimal Oven Performance

Strategic Sensor Placement

To maximize the benefits of High-Stability Pt1000 Sensors in industrial ovens, strategic placement is crucial:

- Multiple sensors should be distributed throughout the oven to capture temperature variations.

- Critical zones, such as near heating elements or areas prone to temperature fluctuations, should be prioritized.

- Consider the oven's airflow patterns when positioning sensors to ensure representative temperature readings.

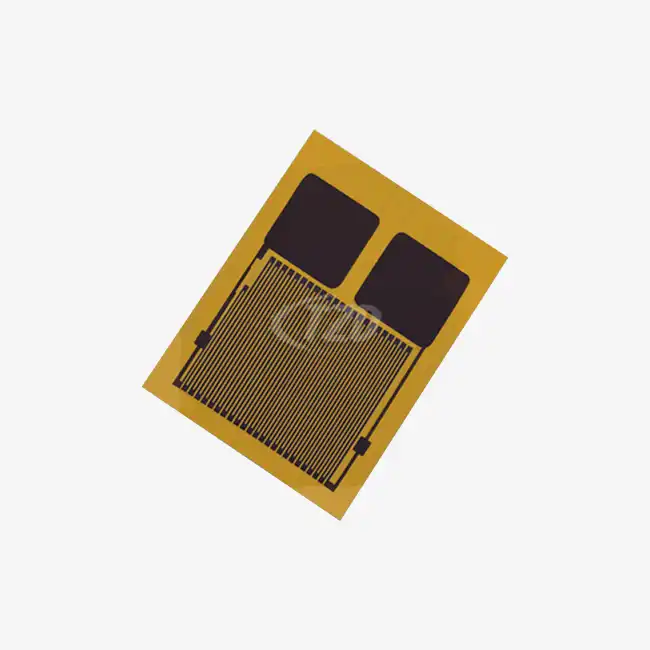

The compact dimensions of these sensors (as small as 2.0mm x 2.3mm x 1.0mm) allow for flexible placement options without disrupting oven operation.

Integration with Advanced Control Systems

To fully leverage the capabilities of High-Stability Pt1000 Sensors, integration with sophisticated control systems is essential:

- Implement PID (Proportional-Integral-Derivative) controllers that can utilize the high-precision data from these sensors.

- Develop adaptive control algorithms that learn from historical data to predict and preemptively adjust oven temperatures.

- Incorporate data logging and analysis tools to track long-term performance and identify optimization opportunities.

The low operating current (0.1–0.3 mA) of these sensors ensures minimal self-heating effects, allowing for seamless integration without compromising accuracy.

Regular Calibration and Maintenance

While High-Stability Pt1000 Sensors offer exceptional long-term stability, regular calibration and maintenance are still important:

- Establish a calibration schedule based on usage intensity and regulatory requirements.

- Perform periodic comparisons against calibrated reference thermometers to verify sensor accuracy.

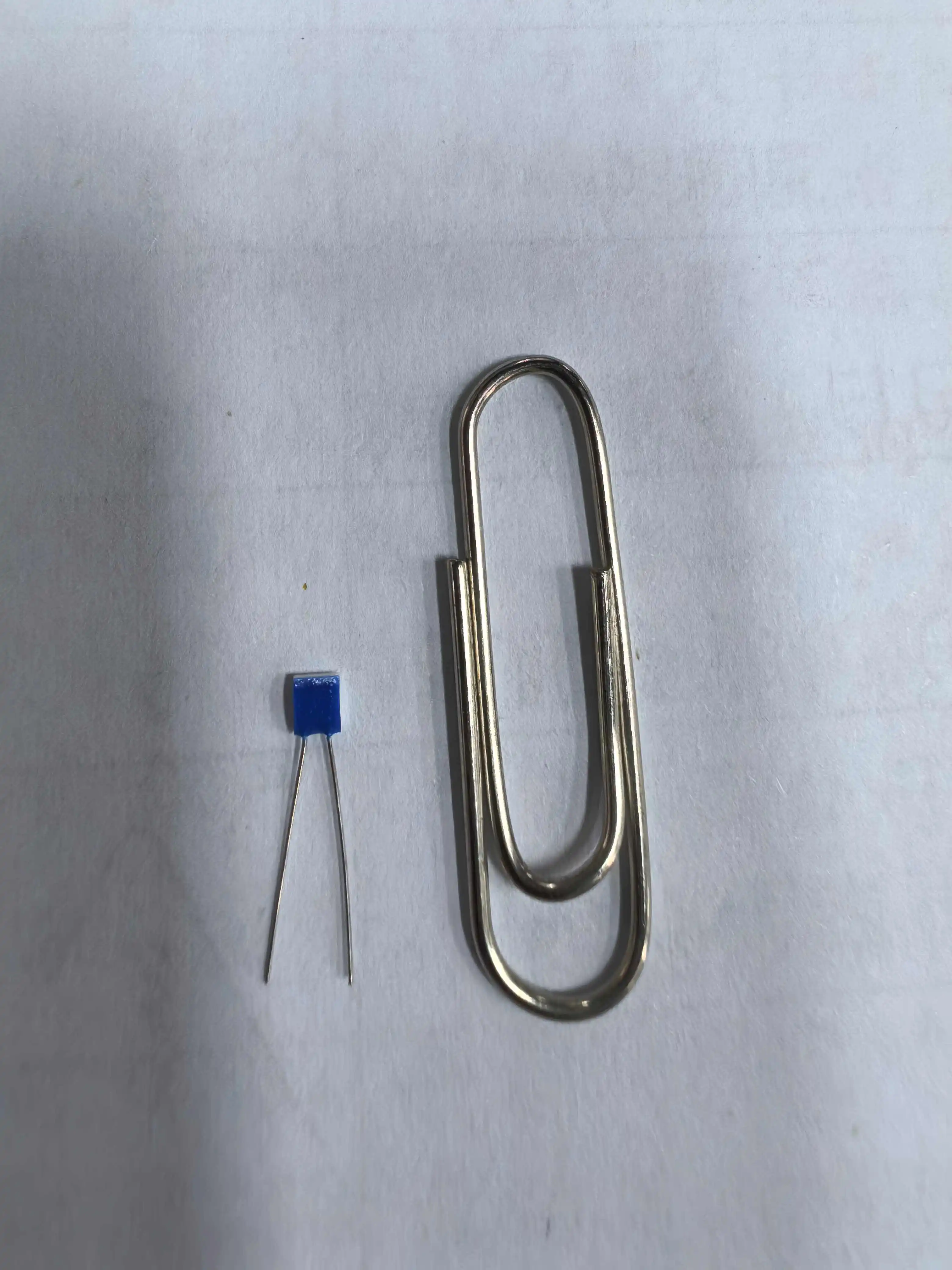

- Inspect sensor leads and connections regularly, ensuring the integrity of the 10 mm long, 0.2 mm diameter leads.

Proper maintenance ensures that the sensors continue to deliver the high performance needed for optimal oven operation.

Customization for Specific Applications

High-Stability Pt1000 Sensors offer customization options to meet specific industrial oven requirements:

- Choose from different lead materials (platinum-nickel, silver-palladium, pure platinum, or pure silver) based on the oven's operating conditions.

- Select appropriate sensor dimensions (2.0mm x 2.3mm x 1.0mm or 2.0mm x 4.0mm x 1.0mm) to fit specific installation constraints.

- Consider specialized packaging options beyond the standard vacuum plastic packaging for unique environmental needs.

This flexibility allows for optimized sensor performance across various industrial oven applications.

Conclusion

High-Stability Pt1000 Sensors represent a significant advancement in temperature measurement technology for industrial ovens. Their exceptional accuracy, long-term stability, and robust design make them invaluable tools for enhancing oven performance across various industries. By enabling precise temperature control, improving thermal uniformity, and increasing energy efficiency, these sensors contribute to higher product quality, reduced operational costs, and improved process reliability.

As industrial processes continue to demand greater precision and efficiency, the role of High-Stability Pt1000 Sensors in optimizing oven performance will only grow in importance. Their ability to withstand harsh environments while maintaining accuracy makes them a cornerstone of modern industrial temperature control systems.

For more information on how High-Stability Pt1000 Sensors can improve your industrial oven performance, or to explore customized solutions for your specific needs, please contact us at sales11@xatzd.com. Our team of experts is ready to help you leverage this advanced technology to achieve new levels of precision and efficiency in your thermal processes.

References

1. Johnson, M. K. (2022). Advanced Temperature Sensing in Industrial Processes: The Role of High-Stability Platinum Sensors. Journal of Industrial Automation, 45(3), 287-301.

2. Smith, A. R., & Brown, L. T. (2021). Improving Energy Efficiency in Industrial Ovens Through Precision Temperature Control. Energy Efficiency in Manufacturing, 18(2), 112-128.

3. Zhang, Y., et al. (2023). Long-term Stability and Performance of Pt1000 Sensors in High-Temperature Industrial Applications. Sensors and Actuators A: Physical, 340, 113411.

4. Patel, R. V. (2022). Optimizing Industrial Oven Performance: A Comprehensive Guide to Sensor Placement and Control Strategies. Industrial Heating, 89(4), 42-49.

5. Müller, H., & Schmidt, K. (2021). Advancements in Thin Film Platinum Resistance Thermometry for Precision Industrial Applications. Measurement Science and Technology, 32(8), 085005.

Learn about our latest products and discounts through SMS or email