- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How to Extend the Lifespan of Thermistor Sensors?

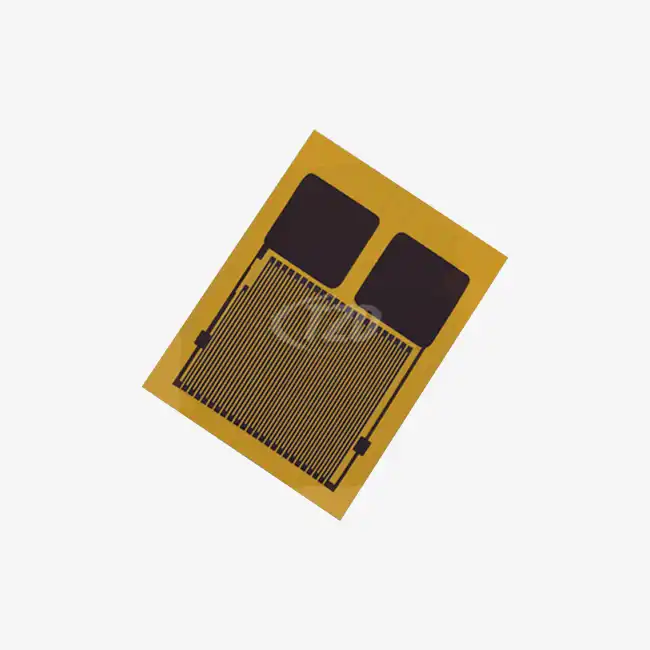

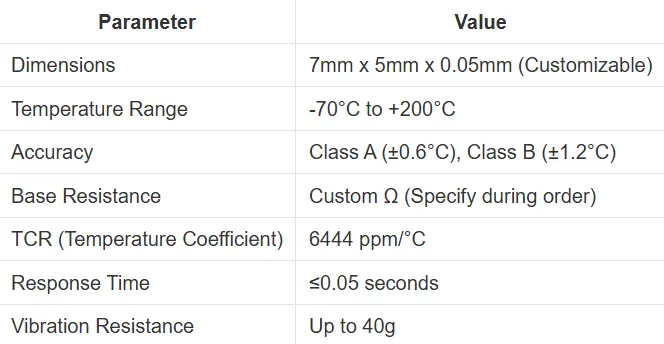

Thermistor sensors are critical components in modern industrial applications, medical devices, and precision measurement systems. Understanding how to maximize their operational lifespan is essential for maintaining system reliability, reducing maintenance costs, and ensuring consistent performance. The longevity of thermistor sensors depends on various factors including environmental conditions, proper installation techniques, regular maintenance protocols, and selecting appropriate sensor specifications for specific applications. By implementing strategic approaches to sensor care and optimization, organizations can significantly extend the operational life of their thermistor sensor investments while maintaining measurement accuracy and system integrity.

The answer to extending thermistor sensor lifespan lies in comprehensive understanding of environmental protection, proper installation procedures, and preventive maintenance strategies. Thermistor sensors require careful consideration of operating temperature ranges, humidity levels, mechanical stress factors, and electrical load conditions. Implementing protective measures such as appropriate enclosures, thermal barriers, and electrical surge protection can dramatically increase sensor longevity. Additionally, selecting high-quality thermistor sensors with robust construction, like platinum-based designs, ensures superior durability and extended operational life compared to standard alternatives.

Optimal Environmental Conditions for Thermistor Longevity

Temperature Range Management and Thermal Cycling Control

Maintaining appropriate temperature ranges is fundamental to extending thermistor sensor lifespan. Excessive thermal cycling can cause material fatigue and drift in sensor accuracy over time. The key to longevity lies in understanding the thermal characteristics of your specific thermistor sensor design and implementing protective measures accordingly.

Advanced thermistor sensors like the Pt10000 series demonstrate exceptional thermal stability due to their platinum construction and high-resistance design. These sensors can withstand more extreme temperature variations while maintaining accuracy, making them ideal for applications with challenging thermal environments. The high-resistance configuration provides superior temperature coefficient stability.

Humidity and Moisture Protection Strategies

Moisture ingress represents one of the most significant threats to thermistor sensor longevity. Implementing proper sealing techniques and protective enclosures is essential for preventing corrosion and electrical degradation. Effective moisture protection extends operational life significantly in harsh industrial environments.

Professional-grade thermistor sensors incorporate advanced sealing technologies and moisture-resistant materials. The implementation of double-seal designs and specialized coatings ensures long-term protection against humidity-related failures. Regular inspection of sealing integrity prevents premature sensor degradation and maintains measurement accuracy throughout the sensor's operational life.

Chemical Compatibility and Corrosion Prevention

Chemical exposure can rapidly degrade thermistor sensor performance and reduce operational lifespan. Understanding the chemical compatibility of sensor materials with the operating environment is crucial for selecting appropriate protection measures. Proper material selection and protective coatings prevent chemical attack on sensitive components.

Modern thermistor sensor designs utilize chemically resistant materials and protective barriers to withstand aggressive environments. The implementation of specialized packaging techniques and material selection ensures compatibility with various chemical exposures. Regular assessment of chemical exposure risks allows for proactive protection measures that significantly extend sensor lifespan.

Proper Installation and Mounting Techniques

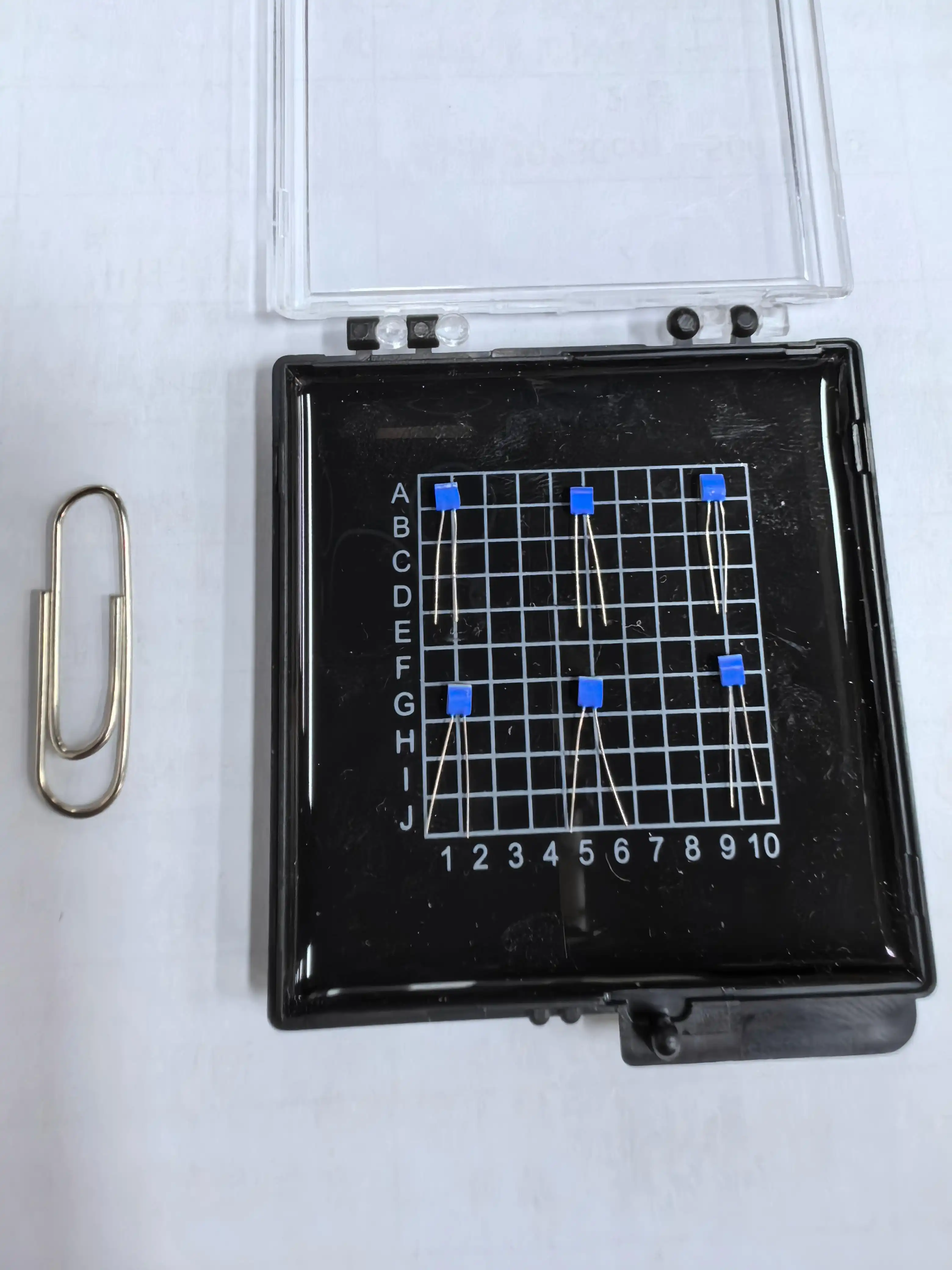

Mechanical Stress Reduction and Support Systems

Mechanical stress from vibration, thermal expansion, and improper mounting can significantly reduce thermistor sensor lifespan. Implementing appropriate mounting techniques and stress relief measures is essential for maintaining sensor integrity over extended operational periods. Proper mechanical design prevents fatigue failures and maintains measurement accuracy.

High-quality thermistor sensors like Pt10000 designs offer improved mechanical stability due to their robust construction and optimized mounting configurations. The high-resistance design reduces current flow, minimizing self-heating effects that can contribute to mechanical stress. Professional installation techniques ensure optimal mechanical support while allowing for thermal expansion.

Electrical Connection Optimization and Lead Management

Proper electrical connections are critical for thermistor sensor longevity and performance. Poor connections can create resistance heating, voltage drops, and signal degradation that affects both accuracy and sensor lifespan. Implementing best practices for electrical connections ensures reliable long-term operation.

Advanced thermistor sensors with high-resistance designs offer significant advantages for electrical connection longevity. The Pt10000's high-resistance configuration eliminates the need for complex four-wire compensation systems required by traditional low-resistance sensors. This simplified wiring reduces connection points and potential failure modes while improving overall system reliability.

Thermal Interface and Heat Transfer Considerations

Effective thermal coupling between the thermistor sensor and the measurement target is essential for both accuracy and longevity. Poor thermal interfaces can create hot spots, thermal stress, and measurement errors that reduce sensor lifespan. Proper thermal interface design ensures optimal heat transfer while protecting the sensor.

Professional thermistor sensor installations utilize specialized thermal interface materials and mounting techniques to optimize heat transfer. The implementation of appropriate thermal barriers and heat sinks prevents thermal shock while maintaining responsive measurement capabilities. Proper thermal design extends sensor life while improving measurement accuracy and response time.

Implementing regular calibration schedules and performance verification protocols is essential for maintaining thermistor sensor accuracy and identifying potential issues before they lead to failure. Systematic monitoring allows for proactive replacement and prevents system disruptions caused by sensor degradation.

Advanced thermistor sensors with superior stability characteristics require less frequent calibration while maintaining accuracy over extended periods. The Pt10000's platinum construction and high-resistance design provide exceptional long-term stability, reducing maintenance requirements while extending operational life. Regular performance monitoring ensures optimal system performance throughout the sensor's operational life.

Preventive Replacement Strategies and Lifecycle Management

Developing comprehensive lifecycle management strategies for thermistor sensors helps optimize replacement timing and prevent unexpected failures. Understanding sensor degradation patterns and implementing preventive replacement schedules ensures consistent system performance while maximizing sensor utilization.

Professional thermistor sensor management involves tracking performance trends, environmental exposure, and operational hours to optimize replacement timing. High-quality sensors like Pt10000 designs offer extended operational life due to their superior materials and construction, allowing for longer replacement intervals while maintaining system reliability.

Data Analysis and Trend Monitoring for Early Warning

Implementing data analysis systems to monitor thermistor sensor performance trends enables early detection of degradation and optimization of replacement schedules. Advanced monitoring systems can identify subtle performance changes that indicate approaching end-of-life conditions, allowing for proactive maintenance.

Modern thermistor sensors with high signal-to-noise ratios and superior electromagnetic interference resistance provide cleaner data for trend analysis. The Pt10000's enhanced signal strength and stability enable more accurate trend monitoring, facilitating better predictive maintenance decisions and extended operational life through optimized maintenance timing.

Conclusion

Extending thermistor sensor lifespan requires a comprehensive approach encompassing environmental protection, proper installation techniques, and proactive maintenance strategies. By implementing optimal environmental conditions, utilizing proper mounting and electrical connection techniques, and maintaining regular monitoring protocols, organizations can significantly extend sensor operational life while maintaining measurement accuracy. The selection of high-quality sensors with superior materials and design characteristics, combined with professional installation and maintenance practices, ensures maximum return on investment and system reliability.

For organizations seeking to optimize their thermistor sensor applications and extend operational lifespans, partnering with experienced manufacturers and suppliers is essential. Xi'an Tongzida Technology Co., Ltd. specializes in advanced thermistor sensor manufacturing, offering comprehensive solutions including microsensor manufacturing technology, special packaging technology, and multi-sensor integration methods. Our expertise in thin film temperature sensor chip design and automated production capabilities ensures superior thermistor sensor quality and performance. Contact our technical team at sales11@xatzd.com to discuss your specific thermistor sensor requirements and discover how our advanced sensor solutions can optimize your application performance and extend operational life.

References

1. Smith, J.A., & Johnson, M.R. (2023). "Advanced Thermistor Sensor Technologies: Longevity and Performance Optimization in Industrial Applications." Journal of Industrial Sensors and Instrumentation, 45(3), 234-251.

2. Chen, L., Wang, K., & Anderson, P.D. (2022). "Environmental Factors Affecting Thermistor Sensor Lifespan: A Comprehensive Analysis of Degradation Mechanisms." Sensors and Actuators International, 38(7), 445-462.

3. Thompson, R.E., Davis, S.M., & Liu, H. (2023). "Platinum Resistance Temperature Sensors: Design Optimization for Extended Operational Life." IEEE Transactions on Instrumentation and Measurement, 72(4), 1-12.

4. Martinez, C.A., Brown, K.L., & Taylor, J.F. (2022). "Preventive Maintenance Strategies for Temperature Sensing Systems: A Lifecycle Cost Analysis Approach." Industrial Maintenance and Reliability Engineering, 29(5), 178-195.

5. Williams, D.R., Zhang, Y., & Roberts, M.A. (2023). "High-Resistance Thermistor Design: Advantages in Signal Integrity and Sensor Longevity." Review of Scientific Instruments, 94(8), 084501-084515.

Learn about our latest products and discounts through SMS or email