The Fundamentals of Chip Type Thermal Resistance Temperature Sensors

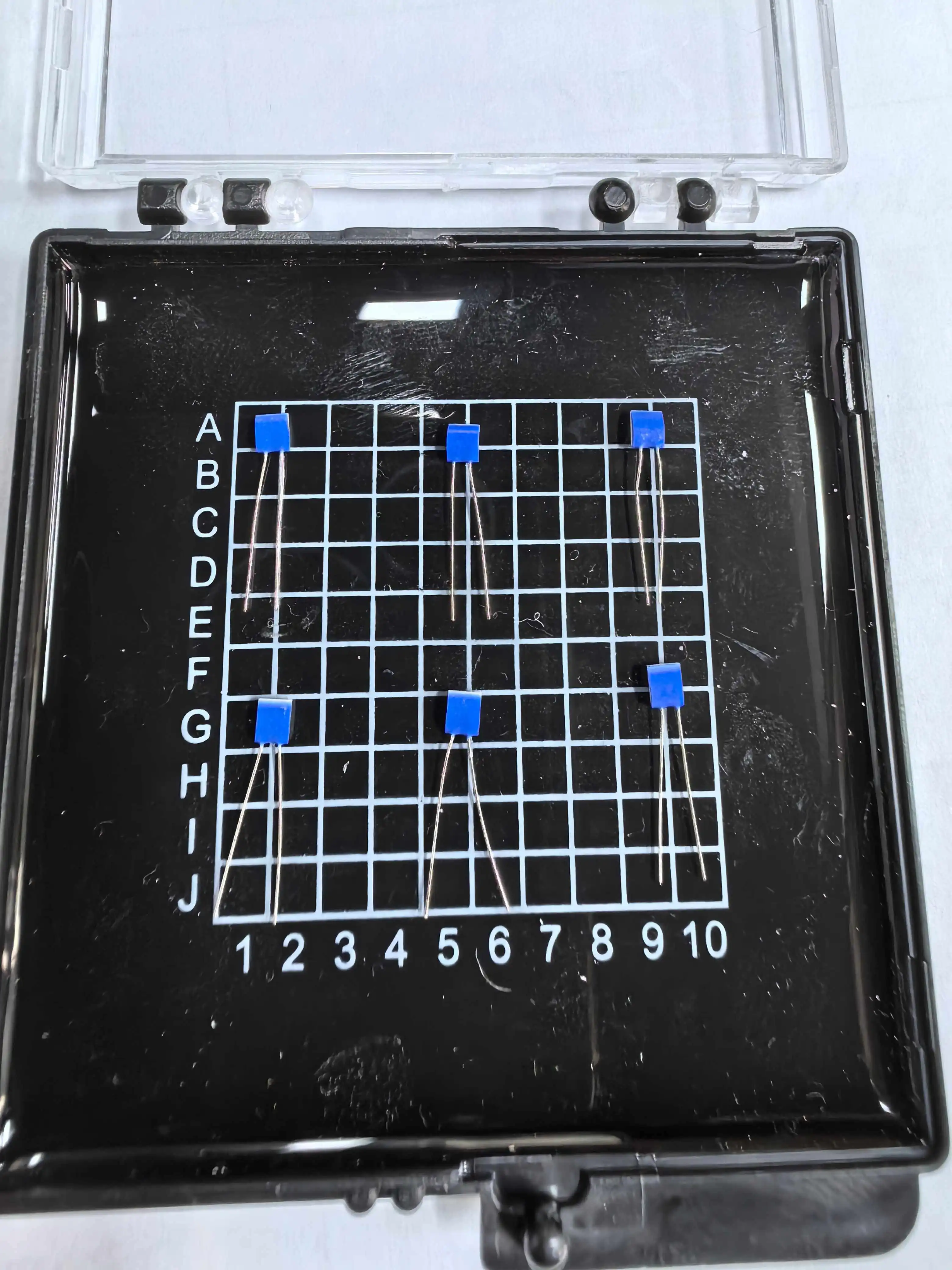

Chip type thermal resistance temperature sensors, also known as thin film platinum resistance temperature detectors (RTDs), are sophisticated devices designed for precise temperature measurement. These sensors leverage the principle of electrical resistance change in platinum materials as temperature fluctuates. The miniature size and robust construction of chip type sensors make them ideal for applications where space is at a premium or where rapid response times are crucial.

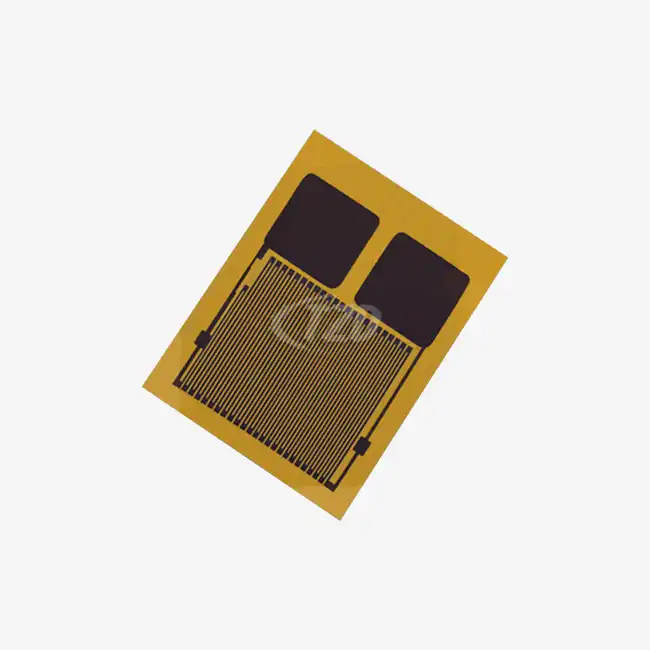

At the heart of these sensors lies a thin film of platinum deposited on a ceramic substrate. This platinum layer is precisely etched to create a serpentine pattern, maximizing the surface area and, consequently, the sensitivity of the sensor. The resistance of this platinum element changes linearly with temperature, allowing for accurate and repeatable temperature measurements across a wide range.

Key Features of Chip Type Thermal Resistance Sensors

Chip type thermal resistance temperature sensors boast several advantageous features that set them apart in the realm of temperature measurement:

- Wide Temperature Range: These sensors can operate effectively from -200°C to +850°C, making them suitable for diverse applications from cryogenics to high-temperature industrial processes.

- High Accuracy: With tolerances as tight as ±0.01 Ω, chip type sensors offer exceptional precision in temperature measurement.

- Excellent Stability: Long-term stability drift of ≤0.04% ensures reliable measurements over extended periods.

- Rapid Response: Response times as low as 0.05 seconds enable real-time temperature monitoring in dynamic environments.

- Durability: These sensors can withstand vibrations up to 40g and impacts up to 100g, making them suitable for rugged industrial and automotive applications.

The combination of these features makes chip type thermal resistance temperature sensors indispensable in industries ranging from aerospace and automotive to medical and industrial process control.

IEC Standards and Their Impact on Sensor Design and Performance

The International Electrotechnical Commission (IEC) plays a pivotal role in setting global standards for electrical, electronic, and related technologies. In the realm of temperature measurement, IEC 60751 stands out as the cornerstone standard for platinum resistance thermometers. This standard has a profound impact on the design, manufacturing, and performance evaluation of chip type thermal resistance temperature sensors.

Key Aspects of IEC 60751

IEC 60751 outlines several critical parameters that chip type thermal resistance sensors must adhere to:

- Temperature Coefficient: The standard specifies a temperature coefficient of 3850 ppm/°C for platinum sensors. This ensures consistency in sensor behavior across different manufacturers and applications.

- Accuracy Classes: IEC 60751 defines various tolerance classes (e.g., Class A, Class B) that specify the allowable deviation from the standard resistance-temperature relationship.

- Temperature Range: The standard covers a broad temperature range from -200°C to +850°C, encompassing most industrial and scientific applications.

- Stability Requirements: Long-term stability is crucial for reliable temperature measurement. IEC 60751 sets benchmarks for acceptable drift over time.

Adherence to these standards ensures that chip type thermal resistance temperature sensors from different manufacturers can be interchangeable, simplifying system design and maintenance for end-users.

Impact on Sensor Manufacturing

The rigorous requirements set forth by IEC 60751 have significant implications for sensor manufacturers:

- Material Selection: High-purity platinum is essential to meet the specified temperature coefficient and stability requirements.

- Manufacturing Precision: Achieving the tight tolerances demanded by the standard requires advanced thin-film deposition and etching techniques.

- Quality Control: Stringent testing and calibration procedures are necessary to ensure compliance with accuracy classes.

- Innovation Drive: The standards challenge manufacturers to develop new technologies and processes to improve sensor performance while maintaining compliance.

By adhering to these standards, manufacturers like Xi'an Tongzida Technology Co., Ltd. ensure that their chip type thermal resistance temperature sensors meet global quality benchmarks and can be reliably used in critical applications worldwide.

Applications and Future Trends in Chip Type Thermal Resistance Sensors

The versatility and reliability of chip type thermal resistance temperature sensors have led to their widespread adoption across numerous industries. Their compact size, high accuracy, and robust performance make them ideal for a variety of applications, from precise laboratory measurements to harsh industrial environments.

Key Application Areas

- Industrial Process Control: In manufacturing and chemical processing, these sensors provide critical temperature data for maintaining optimal production conditions and ensuring product quality.

- Automotive Industry: Chip type sensors are used in engine management systems, exhaust gas recirculation, and battery temperature monitoring in electric vehicles.

- Aerospace: The sensors' ability to withstand extreme conditions makes them suitable for aircraft engine monitoring and environmental control systems.

- Medical Equipment: Precise temperature control is crucial in medical devices such as incubators, sterilizers, and diagnostic equipment.

- HVAC Systems: These sensors enable efficient temperature control in buildings, contributing to energy conservation efforts.

Emerging Trends and Future Developments

The field of chip type thermal resistance temperature sensors continues to evolve, driven by technological advancements and changing industry needs:

- Miniaturization: Ongoing efforts to reduce sensor size while maintaining or improving performance will open up new application possibilities, especially in wearable technology and IoT devices.

- Enhanced Durability: Research into new materials and coating technologies aims to improve sensor longevity in corrosive or high-wear environments.

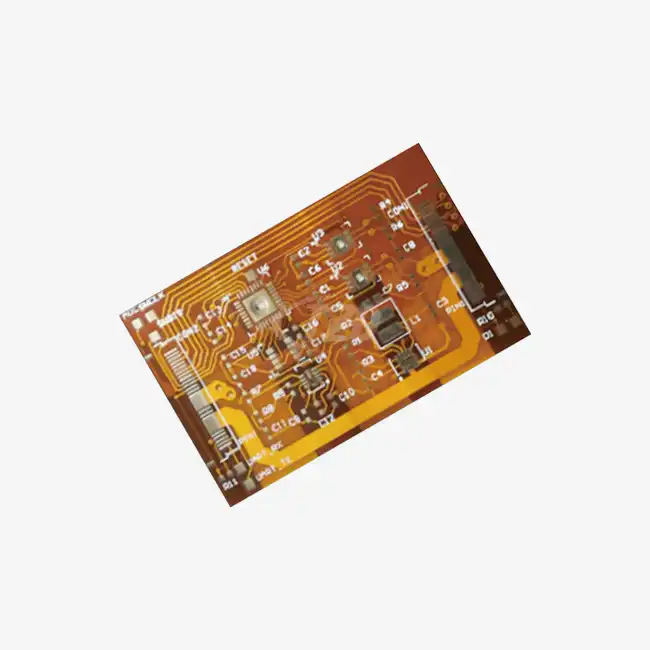

- Integrated Solutions: The trend towards combining temperature sensors with other sensing modalities (e.g., pressure, humidity) in single chip packages is likely to continue, offering more comprehensive environmental monitoring capabilities.

- Smart Sensors: Integration of microprocessors with chip type sensors will enable on-board signal processing, self-diagnostics, and direct digital output, simplifying system integration.

- Wider Temperature Ranges: Ongoing research aims to extend the operational range of these sensors, particularly at extreme high temperatures, to meet the demands of emerging industries such as fusion energy and space exploration.

As these trends materialize, the importance of adherence to IEC standards will only grow, ensuring that innovations in chip type thermal resistance temperature sensors continue to meet the rigorous demands of industry and scientific research.

Conclusion

Chip type thermal resistance temperature sensors, guided by IEC standards, have become indispensable tools in modern temperature measurement applications. Their combination of accuracy, stability, and versatility makes them suitable for a wide range of industries, from precision manufacturing to cutting-edge scientific research. As technology continues to advance, these sensors will undoubtedly play an even more critical role in ensuring safety, efficiency, and innovation across various sectors.

For those seeking high-quality chip type thermal resistance temperature sensors that adhere to the strictest IEC standards, Xi'an Tongzida Technology Co., Ltd. offers a comprehensive range of solutions. With our commitment to quality and innovation, we continue to push the boundaries of what's possible in temperature sensing technology. To learn more about our products and how they can benefit your applications, please contact us at sales11@xatzd.com.