- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How to prevent the risk of temperature runaway in dialysis machines? Tongzida Medical PT1000 safeguards patient safety

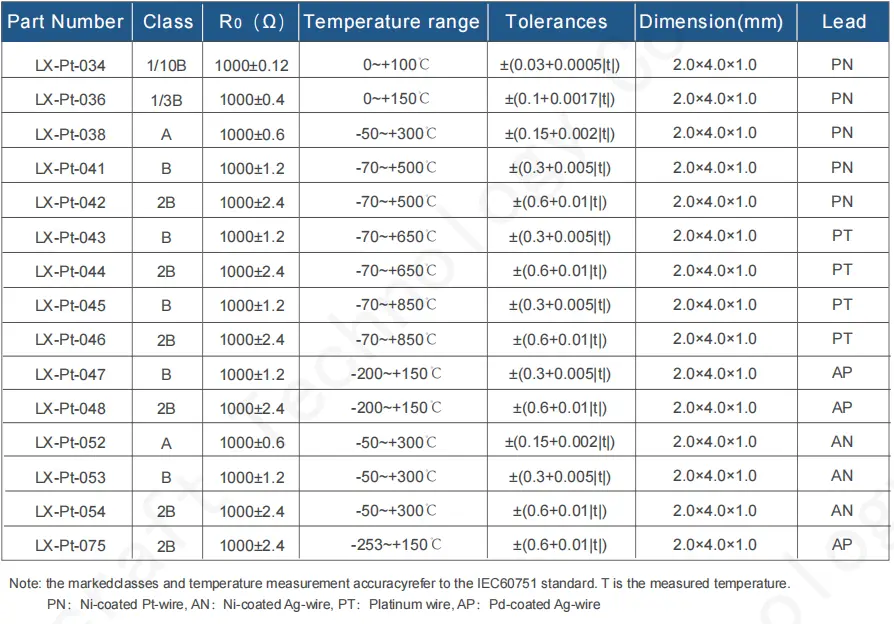

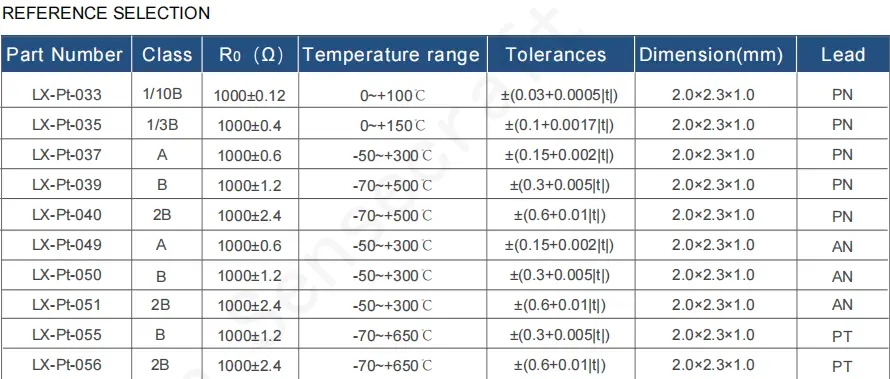

The liquid temperature of the hemodialysis machine is directly related to the patient's life safety and needs to be stably controlled at 37 ± 0.5 ℃. Traditional sensors often cause equipment alarms and even medical risks due to disinfection corrosion and accuracy drift. The PT1000 sensor for dialysis machine is customized for medical scenarios and has become the core safety component of dialysis equipment with high stability and biocompatibility.

H2: Rigid requirements for temperature sensors in dialysis machines

The blood circuit and dialysate circuit of the dialysis machine require precise temperature measurement, and the sensors must meet the following requirements: measurement accuracy of ± 0.1 ℃, tolerance to high temperature sterilization at 134 ℃, biocompatibility (in accordance with ISO 10993 standard), and resistance to electromagnetic interference (suitable for hospital MRI and other equipment environments). The PT1000 sensor for dialysis machines perfectly matches these stringent requirements with its advantages of low self heating and high stability.

H2: Tongzida PT1000 solves the four major safety pain points of dialysis machines

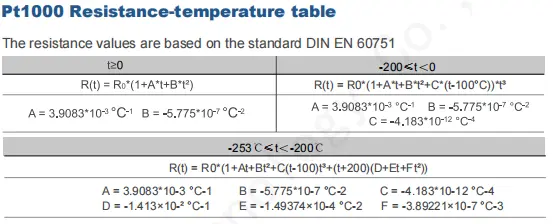

Precision drift prevention and control: using 3850PPM/℃ high temperature coefficient platinum deposition process, the PT1000 sensor dedicated to dialysis machine has a long-term stability of ≤ 0.04% drift for 1000 hours at 500 ℃, avoiding discomfort caused by temperature deviation in patients;

Sterilization environment tolerance: Medical grade stainless steel packaging, supporting ethylene oxide (EO) and high-pressure steam sterilization, with no performance degradation after repeated disinfection;

Biosafety assurance: All components that come into contact with bodily fluids have passed biocompatibility testing, are non-toxic, and have no allergenic reactions, ensuring patient safety;

Strong anti-interference ability: Through IEC 61000-4 electromagnetic compatibility testing, it maintains measurement accuracy even in strong electromagnetic environments in hospitals.

H2: Hospital test: Dialysis machine failure rate reduced from 8% to 0.5%

A certain tertiary hospital's dialysis center once used ordinary sensors, with a monthly equipment failure rate of 8%. After replacing the PT1000 sensor dedicated to the Tongzida dialysis machine, the failure rate dropped to below 0.5%, and the patient complaint rate was reset to zero. The stability of sensors directly improves the safety of diagnosis and treatment, and they are the 'security guards' of our department, "said the director of the dialysis department

H2: Four key dimensions for selecting sensors for dialysis machines

H3: Accuracy level: High precision models within ± 0.05 ℃ must be selected to ensure precise temperature control;

H3: Packaging material: preferably medical grade stainless steel or PEEK material, resistant to disinfection and corrosion;

H3: Connection method: three wire system/four wire system, to offset lead resistance errors;

H3: Certification compliance: Possessing NMPA medical device registration and CE certification, in compliance with YY/T 1478-2016 standard.

References

[1] Medical sensing enters the '0.1 ℃ era'! Rich temperature sensing technology breaks through industry pain points. NetEase News Client, 2025

[2] What are the types of Pt thermistors used in medical equipment. NetEase News Client, 2025

Contact Tongzida immediately to obtain a dedicated PT1000 sensor solution for dialysis machines!

Author information

Author: Mr. Wang from Tongzida Medical Equipment Business Unit

Title: Senior Engineer

Expertise: Research and development of medical equipment sensing technology, with multiple patents for dialysis machine and ventilator sensors, serving over 500 medical institutions.

FAQ

Q1: Can the sensor be adapted to different brands of dialysis machines?

A1: Supports customized lead length and interface specifications, and has been adapted to mainstream brands such as Fresenius and Mindray dialysis machines.

Q2: Does disinfection frequency affect sensor performance?

A2: The design life supports more than 1000 sterilization cycles, with no performance degradation, meeting the daily needs of hospitals.

Xi'an Tongzida Technology Co., Ltd. est un fabricant et fournisseur de premier plan de technologies de thermistance avancées, spécialisé dans la fourniture de capteurs de température haute performance pour les applications industrielles exigeantes. Notre expertise approfondie en fabrication de microcapteurs, en technologies d'encapsulation spécifiques et en méthodes d'intégration multi-capteurs nous permet de garantir l'excellente performance et la fiabilité de nos thermistances. En tant que fournisseur de confiance de solutions de mesure de température de précision, nous proposons un système complet de thermistances, incluant les puces de capteurs, les systèmes de test et les logiciels d'analyse. N'hésitez pas à contacter nos experts techniques. ventes11@xatzd.com Discutez de vos besoins spécifiques en matière de thermistances et découvrez comment nos capacités avancées d'optimisation et de fabrication de résistances thermiques peuvent améliorer les performances et la fiabilité de votre système de mesure de température.

Learn about our latest products and discounts through SMS or email