- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Medical microfluidic chip temperature measurement

How can flexible sensors overcome the accuracy bottleneck in medical microfluidic chip temperature measurement?

In the genetic testing and drug screening of medical microfluidic chips, flexible temperature sensors of medical microfluidic chips are becoming the core solution to break through the limitations of traditional temperature measurement

1: Three major pain points for temperature measurement using medical microfluidic chips

1.1: Microchannel<1mm, rigid sensor cannot fit properly

1.2: Detection error caused by temperature drift (traditional sensor TCR>8000ppm/℃)

1.3: Biological sample activity is affected by temperature fluctuations

2: How to solve the problem of microfluidic temperature measurement with flexible temperature sensors

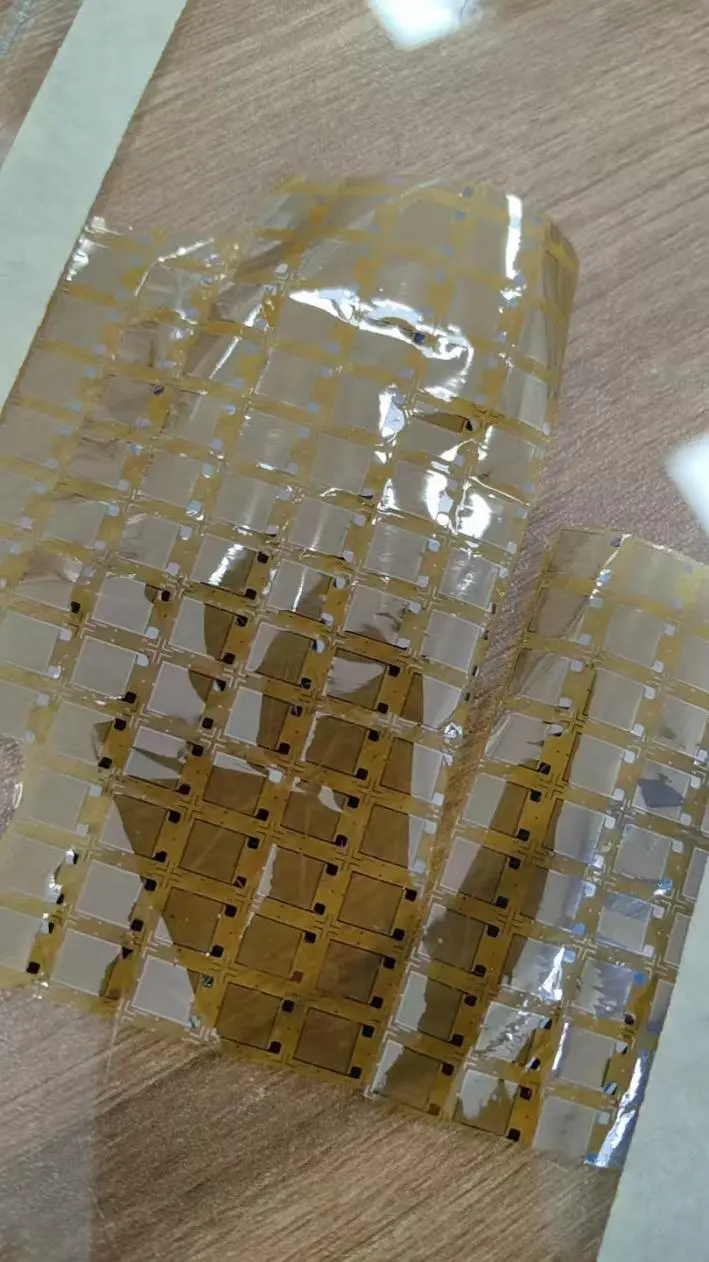

Our medical microfluidic chip flexible temperature sensor adopts a 0.05mm ultra-thin PI substrate, which can bend and attach<1mm microchannels. The TCR is only 6444ppm/℃ (20% lower than the industry average), ensuring A-level accuracy of ± 0.6 ℃.

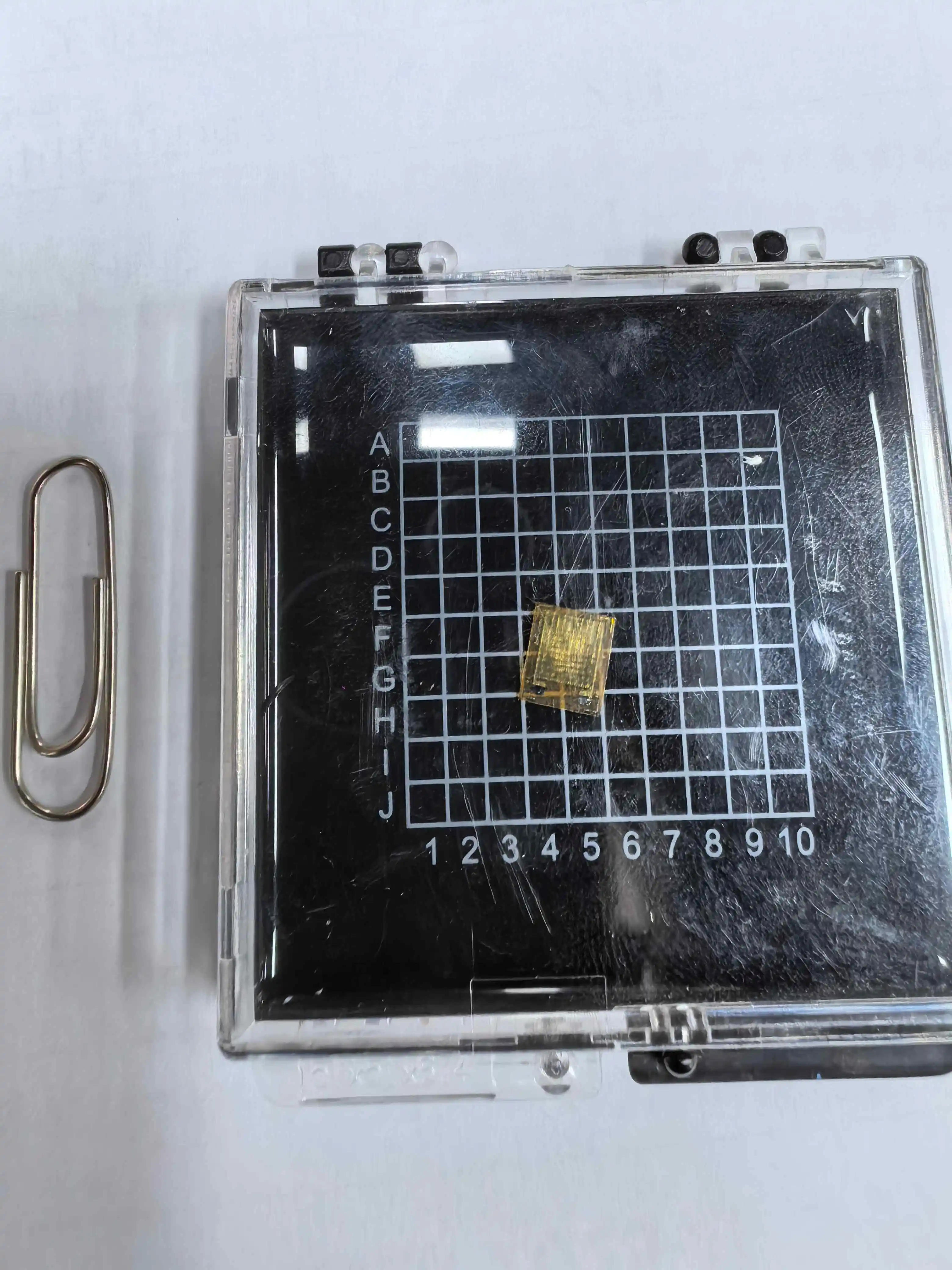

2.1: Size advantage: 7 × 5mm miniaturized design (only 2mm wider than microchannels)

2.2: Material adaptation: Biocompatible coating (Parylene HT) to avoid sample contamination

After a certain genetic testing company used the sensor, the repeatability of microfluidic chip detection increased from 85% to 98%, which is the value of flexible temperature sensors for medical microfluidic chips.

2.3: Practical Case: Bio Bio Microfluidic Gene Testing Project

Scene: COVID-19 nucleic acid detection microfluidic chip (microchannel 0.8mm)

Solution: Customized 5 × 3mm flexible sensor array (with attached chip for import and export)

Effect: Temperature uniformity improved by 40%, detection time reduced by 25%

2.4: Selection Guide: 4 Key Parameters of Medical Microfluidic Sensors

Accuracy (± 0.6 ℃ vs Traditional ± 1.5 ℃)

Base material (medical grade PI/Parylene HT)

Response speed (seconds vs minutes)

References :

White Paper on Temperature Control Technology of Microfluidic Chips (China Medical Device Industry Association, 2023)

Test Report of Bio Microfluidic Project (2024)

SGS Flexible Sensor Temperature Cycle Test Certification (Report No. SH-SGS-202405)

Conclusion+CTA (bold keywords): For medical microfluidic chip developers who pursue high precision and compatibility, flexible temperature sensors for medical microfluidic chips are the optimal solution for cost reduction and efficiency improvement. Contact us immediately for samples and customized solutions!

Author Information: Liu Gong | Chief Consultant for Flexible Sensor Medical Applications (10 years of experience in medical sensor research and development, leading 3 NMPA filing projects)

FAQ:

Q1: Can the sensor withstand the chemical reagents of microfluidic chips?

A: Support customized acid and alkali resistant coatings (such as polytetrafluoroethylene).

Q2: What is the minimum order quantity for bulk procurement?

A: Starting from 500 pieces in small batches.

Q3: Do you provide temperature drift calibration services?

A: Full inspection before leaving the factory+temperature drift curve report, lifetime free calibration support.

Xi'an Tongzida Technology Co., Ltd. is a leading manufacturer and supplier of advanced thermistor technology, dedicated to providing high-performance temperature sensors for demanding industrial applications. We have comprehensive expertise in microsensor manufacturing technology, special packaging technology, and multi-sensor integration methods to ensure excellent performance and reliability of thermistors. As a trusted supplier of precision temperature measurement solutions, we offer a complete thermistor system, including core sensitive chips, testing systems, and analysis software. Please contact our technical experts sales11@xatzd.com Discuss your specific thermistor requirements and learn how our advanced resistor temperature optimization and manufacturing capabilities can improve the performance and reliability of your temperature measurement system

Learn about our latest products and discounts through SMS or email