The Evolution of Thin Flexible Temperature Sensing Films

Understanding the Technology Behind Flexible Temperature Sensors

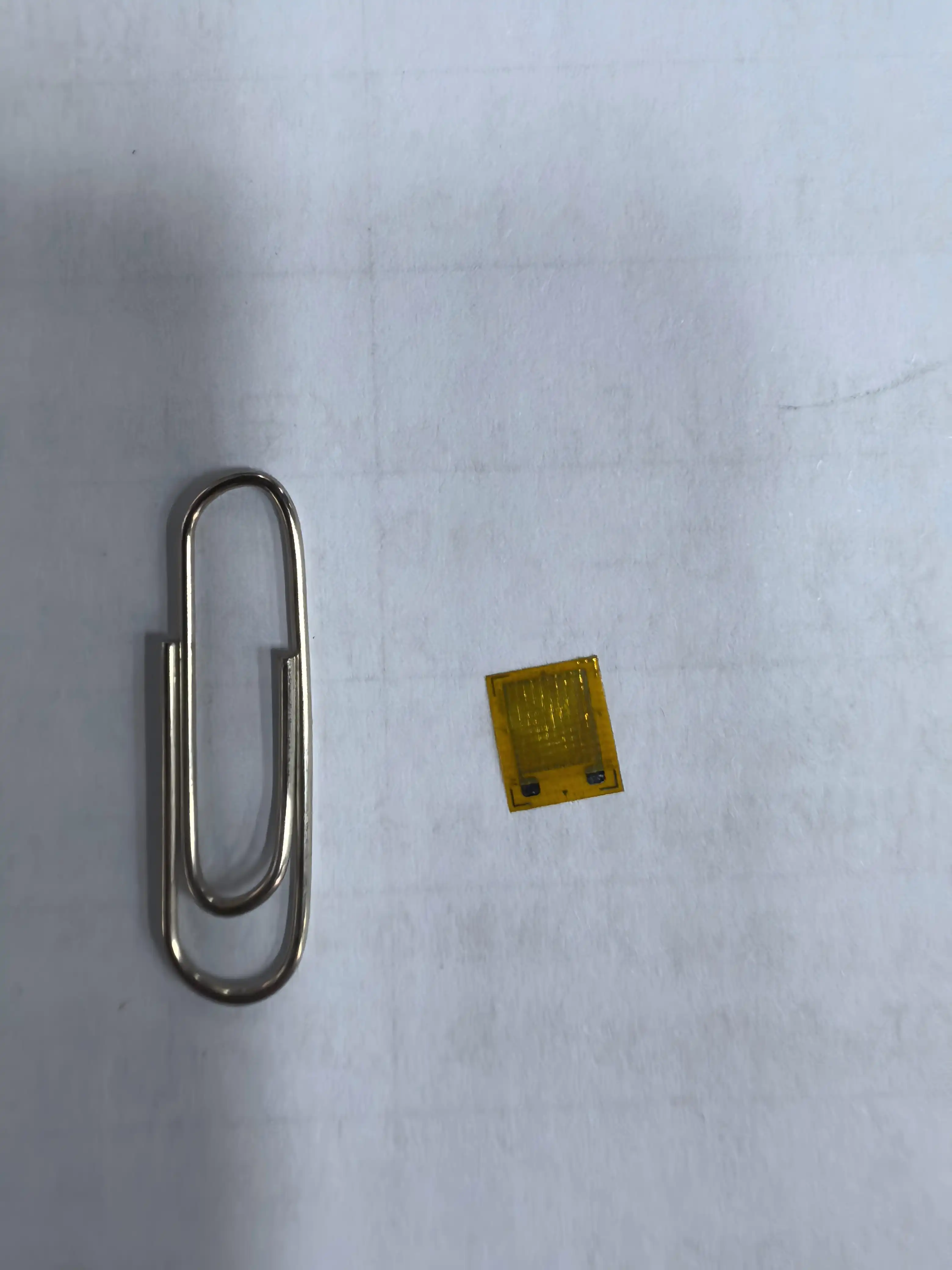

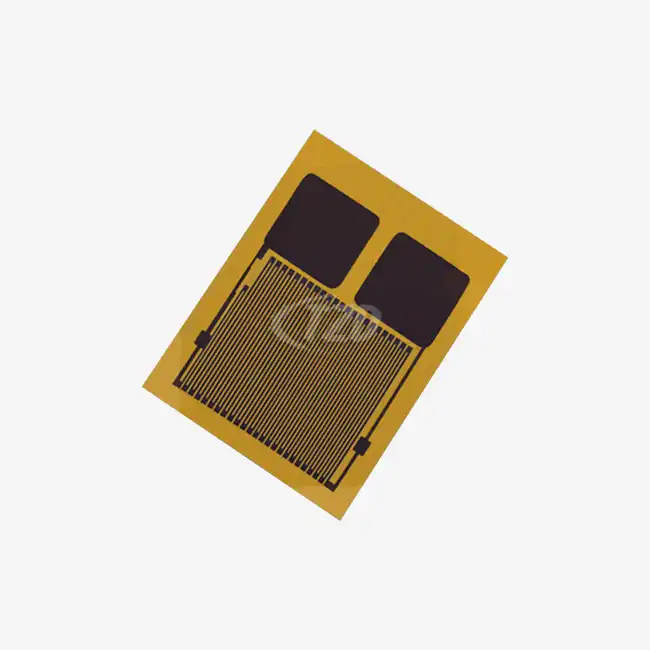

Thin flexible temperature sensing films represent a significant leap forward in temperature measurement technology. These films are composed of advanced materials that can detect minute temperature changes while maintaining flexibility and durability. The core of this technology lies in the use of thin-film platinum resistors, which offer exceptional accuracy and stability across a wide temperature range.

These sensors typically utilize a temperature coefficient of 3850ppm/℃, allowing them to measure temperatures from -200℃ to +850℃ with remarkable precision. The thin-film design enables rapid response times, often as quick as 0.05 seconds, making them ideal for applications requiring real-time temperature monitoring.

Advancements in Manufacturing Processes

The production of thin flexible temperature sensing films involves sophisticated manufacturing processes. Companies at the forefront of this technology have established dedicated platforms for design, processing, packaging, and testing of these sensitive chips. These platforms often incorporate automated production lines capable of producing sensors for various temperature ranges, including room temperature, high temperature, and ultra-low temperature applications.

Quality control is paramount in the production of these sensors. Many manufacturers adhere to strict quality management systems, such as ISO9001, and obtain certifications like ROHS and CE to ensure their products meet international standards. The manufacturing process allows for customization in size, ranging from 1.2mm to 4.0mm, and the use of various lead materials such as platinum nickel, silver nickel, or pure platinum, depending on the specific application requirements.

Key Features and Performance Metrics

The performance of thin flexible temperature sensing films is characterized by several key metrics. These include:

- Accuracy: Typically within ± 0.01 Ω

- Long-term stability drift: ≤ 0.04%

- Response time: As low as 0.05 seconds

- Vibration resistance: Up to 40g

- Impact resistance: Up to 100g

These impressive specifications make thin flexible temperature sensing films suitable for demanding applications across various industries, including industrial processes, medical devices, automotive systems, and aerospace technology.

Applications of Flexible Temperature Sensing in Smart Textiles

Enhancing Athletic Performance and Health Monitoring

The integration of thin flexible temperature sensing films into athletic wear has opened up new avenues for performance optimization and health monitoring. These smart textiles can provide real-time body temperature data, allowing athletes and coaches to make informed decisions about training intensity and duration. For endurance athletes, such as marathon runners or cyclists, this technology can help prevent heat-related illnesses by alerting them to dangerous rises in core body temperature.

In the realm of health monitoring, these sensors can be incorporated into everyday clothing to track body temperature fluctuations continuously. This can be particularly beneficial for monitoring patients with chronic conditions, the elderly, or individuals recovering from illnesses. The non-invasive nature of these sensors makes them ideal for long-term use without causing discomfort.

Revolutionizing Personal Comfort and Climate Control

Smart textiles equipped with flexible temperature sensors are transforming the concept of personal climate control. Imagine jackets that can automatically adjust their insulation properties based on your body temperature and the ambient environment. These adaptive garments can provide optimal comfort in varying weather conditions, reducing the need for layering or frequent clothing changes.

In the automotive industry, these sensors are being integrated into car seats to create personalized comfort zones for each passenger. By continuously monitoring body temperature and adjusting seat heating or cooling accordingly, these systems can significantly enhance the driving experience, especially on long journeys.

Improving Safety in Industrial and Hazardous Environments

The robustness and accuracy of thin flexible temperature sensing films make them invaluable in industrial safety applications. Protective gear for firefighters, for instance, can be equipped with these sensors to monitor both the external temperature of the environment and the firefighter's body temperature. This dual monitoring can prevent heat exhaustion and alert the wearer to dangerous external temperatures.

In chemical plants and other hazardous environments, workwear integrated with these sensors can provide early warning signs of potential overheating in equipment or processes. This proactive approach to temperature monitoring can prevent accidents and improve overall workplace safety.

Future Prospects and Challenges in Flexible Temperature Sensing Technology

Emerging Trends and Potential Applications

The field of flexible temperature sensing is rapidly evolving, with several exciting trends on the horizon. One promising area is the development of self-powered sensors that can harvest energy from body heat or movement, eliminating the need for batteries and making the technology even more seamless and user-friendly.

Another emerging trend is the integration of these sensors with other types of flexible electronics, such as strain sensors or electrochemical sensors. This multi-modal approach could lead to smart textiles capable of monitoring a wide range of physiological parameters simultaneously, providing a more comprehensive picture of an individual's health and environmental conditions.

Overcoming Technical and Practical Challenges

Despite the significant advancements in thin flexible temperature sensing films, several challenges remain. Durability is a key concern, particularly for sensors integrated into clothing that must withstand repeated washing and wear. Researchers are exploring new encapsulation techniques and materials to enhance the longevity of these sensors without compromising their flexibility or accuracy.

Another challenge lies in data interpretation and management. As these sensors become more widespread, there's a need for sophisticated algorithms and AI-powered systems to analyze the vast amounts of temperature data generated. Ensuring the privacy and security of this potentially sensitive information is also a critical consideration as the technology becomes more prevalent in everyday life.

The Role of Collaboration in Advancing the Technology

The future of thin flexible temperature sensing films in smart textiles will likely be shaped by collaborative efforts between various industries. Textile manufacturers, electronics companies, and software developers will need to work closely to create truly integrated and user-friendly products. Collaborations with healthcare providers and sports science experts will be crucial in developing applications that provide meaningful insights and tangible benefits to users.

As the technology matures, we can expect to see more standardization in the industry, which will facilitate wider adoption and interoperability between different smart textile systems. This standardization will be essential for creating an ecosystem of compatible products and services built around flexible temperature sensing technology.

Conclusion

The integration of thin flexible temperature sensing films into smart textiles represents a significant leap forward in wearable technology. From enhancing athletic performance and personal comfort to improving safety in hazardous environments, these innovative sensors are reshaping our interaction with clothing and our environment. As the technology continues to evolve, we can anticipate even more groundbreaking applications that will further blur the line between textiles and technology.

The future of smart textiles is bright, with flexible temperature sensing films playing a crucial role in this revolution. As we overcome current challenges and explore new possibilities, the potential for this technology to improve our lives in meaningful ways is truly exciting. For those interested in learning more about thin flexible temperature sensing films and their applications in smart textiles, please contact us at sales11@xatzd.com.