- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Step-by-Step Guide to 4-Wire PT100 Connections

Mastering 4-wire PT100 connections is essential for achieving maximum temperature measurement accuracy in precision industrial applications where lead resistance compensation is critical for reliable performance. This comprehensive guide provides detailed procedures for implementing 4-wire PT100 sensor connections that eliminate measurement errors caused by lead wire resistance variations, thermal effects, and environmental conditions that compromise accuracy in conventional 2-wire or 3-wire configurations. Professional installation of 4-wire PT100 systems requires understanding of signal routing, grounding practices, and measurement principles that ensure optimal performance in demanding applications. The PT100 sensor represents the gold standard for precision temperature measurement, and proper 4-wire connections unlock its full accuracy potential by providing independent current and voltage measurement paths that eliminate common sources of measurement uncertainty in industrial and laboratory applications requiring the highest precision standards.

Understanding 4-Wire PT100 Connection Principles and Benefits

Fundamental Theory Behind 4-Wire Measurement Systems

The 4-wire PT100 sensor connection method utilizes separate current-carrying and voltage-sensing conductors to eliminate lead resistance effects that compromise measurement accuracy in 2-wire and 3-wire configurations. Current flows through dedicated supply conductors to the PT100 sensor element while voltage measurement occurs through separate sensing wires that carry minimal current, ensuring that lead resistance variations do not affect temperature readings. This configuration provides theoretical measurement accuracy limited only by the PT100 sensor element itself rather than installation variables.

Advanced measurement systems leverage the 4-wire principle to achieve accuracy levels approaching ±0.01°C under laboratory conditions with precision PT100 sensors and calibrated instrumentation. The voltage sensing conductors in 4-wire PT100 systems carry microampere-level currents that produce negligible voltage drops across lead resistances, effectively eliminating this common source of measurement error. Professional applications requiring the highest accuracy invariably specify 4-wire PT100 connections to ensure measurement integrity and system reliability.

Lead Resistance Elimination and Accuracy Improvements

Lead resistance variations due to temperature changes, conductor aging, and environmental factors can introduce significant errors in 2-wire and 3-wire PT100 sensor installations, particularly in long cable runs or harsh environments. The 4-wire configuration completely eliminates these effects by separating current supply from voltage measurement functions, ensuring that PT100 sensor readings remain accurate regardless of lead resistance variations. This advantage becomes critical in applications where temperature accuracy directly impacts product quality, process control, or safety systems.

Professional PT100 sensor installations utilizing 4-wire connections can achieve measurement uncertainties below ±0.1°C even with cable runs exceeding 100 meters, while equivalent 2-wire installations might experience errors of several degrees under similar conditions. The lead resistance elimination capability of 4-wire systems enables flexible sensor placement without compromising accuracy, reducing installation constraints and system design complexity. Modern high-resistance PT100 sensors further enhance these benefits by reducing lead resistance sensitivity while maintaining 4-wire accuracy advantages.

Signal Conditioning and Noise Immunity Advantages

4-wire PT100 sensor connections provide superior noise immunity compared to 2-wire alternatives through differential voltage measurement that rejects common-mode interference and electromagnetic noise present in industrial environments. The separate current and voltage paths enable advanced signal conditioning techniques that optimize measurement accuracy while minimizing susceptibility to electrical interference from motors, drives, and power systems. Professional measurement systems incorporate shielding and grounding practices that maximize the noise immunity benefits of 4-wire PT100 configurations.

Modern 4-wire PT100 sensor transmitters utilize precision analog-to-digital conversion and digital signal processing to achieve measurement resolution below 0.01°C while maintaining excellent noise rejection characteristics. The balanced signal paths in 4-wire systems enable differential amplification that eliminates ground loop effects and common-mode voltages that degrade measurement quality in single-ended configurations. These signal conditioning advantages make 4-wire PT100 sensors ideal for precision applications in electrically noisy environments where measurement accuracy is paramount.

Detailed Wiring Procedures and Connection Standards

Cable Selection and Preparation Requirements

Professional 4-wire PT100 sensor installations require high-quality cables with matched conductor resistances, appropriate insulation ratings, and shielding characteristics suitable for the operating environment and accuracy requirements. Cable selection should consider temperature rating, chemical compatibility, flexibility requirements, and electromagnetic interference levels present in the installation environment. Precision applications typically specify cables with conductor resistance matching within 1% to minimize common-mode errors and ensure optimal 4-wire performance benefits.

Proper cable preparation includes careful stripping procedures that avoid conductor damage, appropriate termination hardware selection, and shield grounding practices that optimize noise immunity while preventing ground loops. PT100 sensor cables require special handling to prevent moisture ingress, conductor oxidation, and insulation damage that could compromise long-term measurement accuracy. Professional installation practices include cable routing procedures that minimize electromagnetic interference pickup and mechanical stress that could affect connection integrity over the sensor's operational life.

Terminal Identification and Connection Sequence

Standard 4-wire PT100 sensor terminals include current supply connections (I+ and I-) and voltage sensing connections (V+ and V-) that must be correctly identified and connected to achieve proper measurement functionality. Color coding standards vary among manufacturers, but typical configurations use red and white for current supply while blue and green serve voltage sensing functions. Professional installations verify terminal identification using manufacturer documentation and continuity testing before completing connections to prevent wiring errors that could damage measurement equipment.

Connection sequence procedures begin with power system isolation, followed by cable preparation, terminal identification verification, and systematic connection of current and voltage conductors according to manufacturer specifications. PT100 sensor wiring requires attention to connection torque specifications, terminal protection methods, and environmental sealing procedures that ensure reliable long-term operation. Advanced installations incorporate connection verification procedures that confirm proper 4-wire functionality before system commissioning and calibration activities.

Grounding and Shielding Best Practices

Effective grounding and shielding practices are essential for maximizing the noise immunity advantages of 4-wire PT100 sensor installations in industrial environments with significant electromagnetic interference sources. Cable shields should be connected to appropriate system ground points using techniques that prevent ground loops while providing effective noise rejection for the voltage sensing conductors. Professional installations evaluate grounding system integrity and implement single-point grounding strategies that optimize measurement accuracy while ensuring personnel safety.

Shield grounding techniques vary with application requirements, but generally involve connection to clean system ground points through appropriate grounding hardware that maintains low-impedance paths for interference currents. PT100 sensor installations in hazardous areas require special grounding considerations that comply with safety regulations while maintaining measurement accuracy requirements. Modern 4-wire measurement systems often incorporate isolated signal conditioning that reduces grounding sensitivity while maintaining excellent noise immunity characteristics for challenging industrial applications.

Testing, Verification, and Troubleshooting Procedures

Connection Verification and Continuity Testing

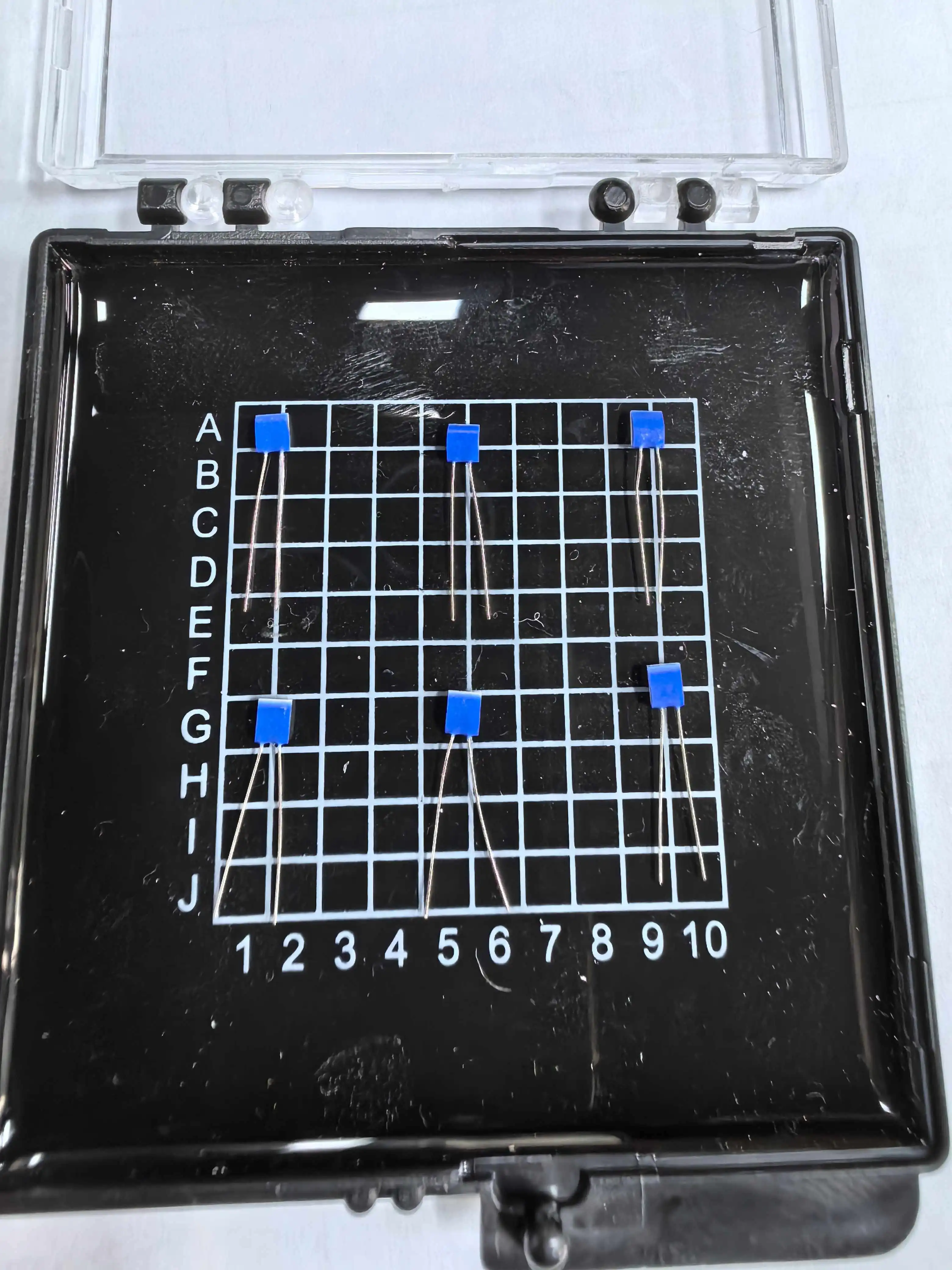

Systematic verification procedures for 4-wire PT100 sensor connections include continuity testing of current supply paths, resistance measurement of voltage sensing circuits, and insulation testing between conductors and ground to ensure proper installation before system commissioning. Professional testing utilizes calibrated instrumentation that can detect connection errors, wire damage, and insulation problems that could compromise measurement accuracy or create safety hazards. Verification procedures should document connection resistance values, insulation levels, and system grounding integrity for maintenance records.

Advanced connection testing includes measurement of lead resistance values for documentation purposes and verification that voltage sensing conductors carry minimal current during normal operation. PT100 sensor systems should be tested at multiple temperatures when possible to verify proper 4-wire operation and confirm that lead resistance variations do not affect measurement accuracy. Professional installations maintain detailed testing records that support troubleshooting activities and provide baseline data for long-term performance monitoring and maintenance planning purposes.

Calibration and Accuracy Verification Methods

4-wire PT100 sensor calibration procedures require precision temperature references and calibrated measurement instrumentation that can verify system accuracy across the intended operating temperature range. Professional calibration utilizes traceable temperature standards such as fixed-point cells, precision temperature baths, or dry-block calibrators that provide known temperature references for accuracy verification. Calibration documentation should include uncertainty analysis that accounts for reference accuracy, measurement system uncertainty, and environmental factors affecting calibration validity.

Field calibration verification procedures for 4-wire PT100 systems can utilize portable calibration equipment that provides convenient accuracy checking without requiring sensor removal or system shutdown. Modern calibration systems incorporate automated procedures that minimize human error while providing comprehensive documentation of sensor accuracy and system performance. PT100 sensor calibration programs should establish appropriate calibration intervals based on application requirements, environmental conditions, and historical accuracy data to ensure continued measurement reliability throughout the sensor's operational life.

Common Problems and Diagnostic Procedures

Typical 4-wire PT100 sensor installation problems include incorrect terminal connections, damaged conductors, inadequate shielding, and grounding issues that compromise measurement accuracy or create intermittent failures. Diagnostic procedures should systematically evaluate each potential problem source using appropriate test equipment and documented troubleshooting procedures that minimize system downtime while ensuring safe working practices. Professional troubleshooting maintains detailed records of problems encountered and solutions implemented to support future maintenance activities.

Advanced diagnostic techniques for 4-wire PT100 systems include signal analysis equipment that can identify noise sources, connection quality assessment tools that detect high-resistance connections, and insulation testing that reveals moisture ingress or contamination problems. Modern PT100 sensor transmitters often incorporate self-diagnostic capabilities that provide continuous monitoring of connection integrity and measurement quality parameters. These diagnostic features enable proactive maintenance that prevents measurement system failures while optimizing accuracy and reliability in critical applications requiring continuous temperature monitoring capabilities.

Conclusion

4-wire PT100 sensor connections provide maximum measurement accuracy by eliminating lead resistance effects through separate current supply and voltage sensing paths. Professional installation requires careful attention to cable selection, proper terminal identification, systematic connection procedures, and comprehensive testing that ensures optimal system performance and long-term reliability in precision temperature measurement applications.

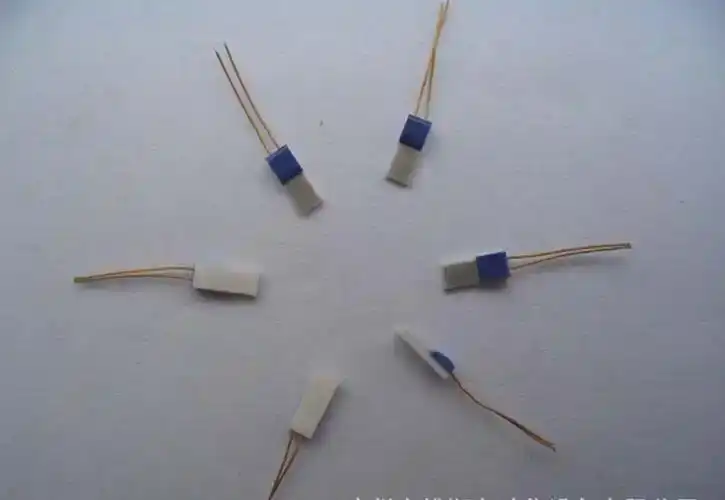

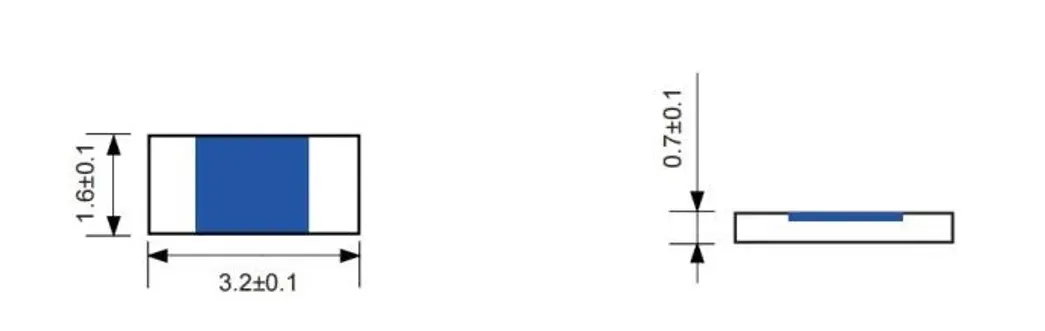

Xi'an Tongzida Technology Co., Ltd. stands as a leading PT100 sensor manufacturer and supplier, offering advanced thin film temperature sensors with comprehensive technical support for 4-wire installation procedures. Our expertise in microsensor manufacturing technology and specialized packaging ensures optimal performance in demanding applications. Contact our technical team at sales11@xatzd.com for professional guidance on PT100 sensor selection and installation requirements.

References

1. Bentley, R.E. (2021). Handbook of Temperature Measurement Vol. 3: Platinum Resistance Thermometry Installation Guide. Springer International Publishing, 4th Edition.

2. McGee, T.D. (2020). Precision Temperature Measurement: 4-Wire RTD Connection Theory and Practice. John Wiley & Sons, Industrial Instrumentation Series.

3. Nicholas, J.V. & White, D.R. (2019). Traceable Temperatures: RTD Wiring and Connection Standards. John Wiley & Sons, Measurement Science Series.

4. Park, S.K. (2021). Industrial Temperature Sensor Installation: Best Practices for 4-Wire Configurations. Elsevier Science & Technology, Process Control Series.

5. Webster, J.G. & Eren, H. (2020). Temperature Measurement Handbook: RTD Connection Methods and Accuracy Optimization. CRC Press, 3rd Edition.

Learn about our latest products and discounts through SMS or email