- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

RTD vs Thermistor: What is the Difference?

When it comes to temperature measurement in industrial and scientific applications, two prevalent sensor types stand out: Resistance Temperature Detectors (RTDs) and thermistors. While both devices measure temperature by detecting changes in electrical resistance, they differ significantly in their composition, operating principles, and performance characteristics. RTDs, particularly the Pt100 Temperature Sensor, utilize pure metals like platinum and offer superior accuracy and stability over a wide temperature range. Thermistors, on the other hand, are made from semiconductor materials and excel in sensitivity and quick response times. Understanding these differences is crucial for selecting the appropriate sensor for specific temperature measurement needs.

Understanding RTDs and Pt100 Temperature Sensors

Resistance Temperature Detectors (RTDs) are precision temperature sensors that operate on the principle of resistance change in pure metals as temperature varies. Among RTDs, the Pt100 Temperature Sensor stands out as a widely used and highly reliable option. The "Pt" in Pt100 denotes platinum, while "100" refers to its resistance of 100 ohms at 0°C.

Composition and Design of Pt100 Sensors

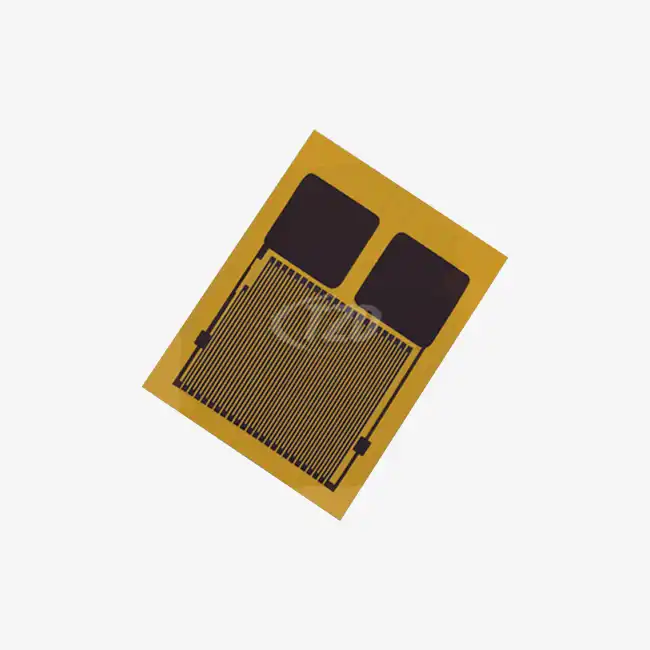

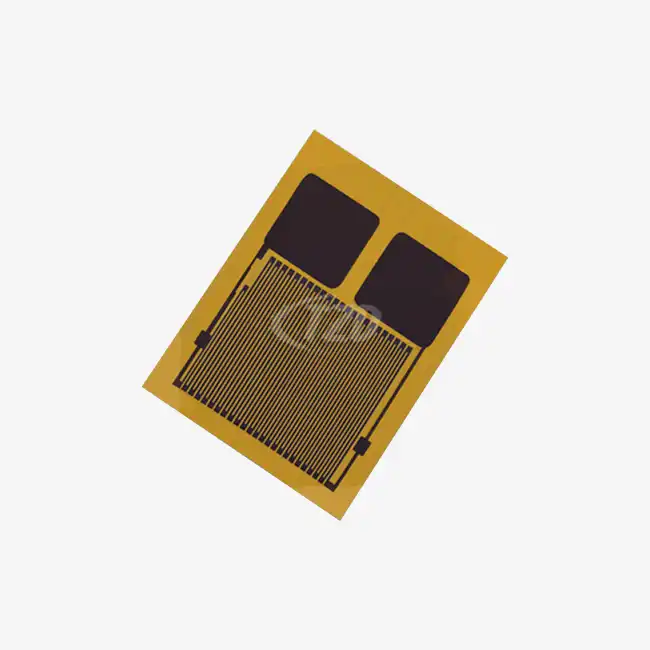

Pt100 sensors are typically constructed using sophisticated thin film technology, which enables the creation of highly compact and robust devices. For instance, the latest generation of advanced Pt100 sensors are often encapsulated in SMD (Surface Mount Device) packages, with incredibly small dimensions such as 3.2mm x 1.6mm x 0.7mm. This remarkable miniaturization makes it possible to integrate these sensors into a wide range of applications where space is at a premium, including medical devices, aerospace systems, and high-density electronic equipment.

Temperature Coefficient and Measurement Range

A key characteristic of Pt100 sensors is their temperature coefficient (TCR), which for many high-quality sensors is 3850 ppm/°C. This coefficient indicates the sensor's sensitivity to temperature changes. The measurement range of Pt100 sensors is impressive, typically spanning from -50°C to +200°C for standard models, with some specialized versions capable of measuring temperatures from -200°C to +850°C.

Accuracy and Stability

Pt100 sensors are renowned for their exceptional accuracy and stability. Advanced models can achieve accuracies of ±0.01 Ω, translating to very precise temperature measurements. Long-term stability is another hallmark of these sensors, with some exhibiting a resistance drift of R₀°C after 1000 hours at 200°C of ≤±0.06%, ensuring reliable measurements over extended periods.

Thermistors: Characteristics and Applications

Thermistors, short for thermal resistors, are another class of temperature sensors that operate on the principle of resistance change with temperature. Unlike RTDs, thermistors are made from semiconductor materials, which gives them distinct characteristics and applications.

Types of Thermistors

Thermistors are primarily categorized into two types: Negative Temperature Coefficient (NTC) and Positive Temperature Coefficient (PTC). NTC thermistors decrease in resistance as temperature increases, while PTC thermistors increase in resistance with temperature. NTC thermistors are more common in temperature sensing applications due to their higher sensitivity.

Sensitivity and Response Time

One of the key advantages of thermistors lies in their exceptional high sensitivity to temperature changes. This unique characteristic renders them perfectly suited for applications that demand rapid detection of even minute temperature fluctuations, such as in medical monitoring devices or precise climate control systems. Thermistors typically exhibit a notably faster response time than RTDs; in fact, certain advanced models can react within a mere 0.05 seconds, ensuring prompt and accurate temperature sensing.

Temperature Range and Accuracy

While thermistors offer excellent sensitivity, their temperature range is generally more limited compared to RTDs. Most thermistors operate effectively in the range of -50°C to +150°C. However, specialized thermistors can be designed for temperatures up to 300°C. The accuracy of thermistors can be high within a narrow temperature range but tends to decrease significantly at temperature extremes.

Comparing RTDs and Thermistors: Making the Right Choice

Choosing between RTDs (like the Pt100 Temperature Sensor) and thermistors depends on the specific requirements of the application. Understanding the strengths and limitations of each type is crucial for making an informed decision.

Accuracy and Stability Considerations

For applications demanding high accuracy over a wide temperature range, RTDs, especially Pt100 sensors, are often the preferred choice. Their linear response and excellent long-term stability make them ideal for precision measurements in industrial processes, laboratory equipment, and calibration systems. Pt100 sensors with a temperature coefficient of 3850 ppm/°C offer consistent performance across their operational range.

Response Time and Sensitivity

When rapid response to temperature changes is crucial, thermistors often have the edge. Their quick response time, which can be as fast as 0.05 seconds, makes them suitable for applications like HVAC systems, automotive temperature monitoring, and medical devices. However, advanced RTDs are catching up, with some models offering response times comparable to thermistors.

Environmental Factors and Durability

RTDs, particularly those made with platinum, exhibit superior resistance to environmental factors. High-quality Pt100 Temperature Sensors can withstand vibrations of up to 40g and impacts of 100g, making them suitable for harsh industrial environments. Thermistors, while generally less robust, can be encapsulated for increased durability in specific applications.

Cost and Size Considerations

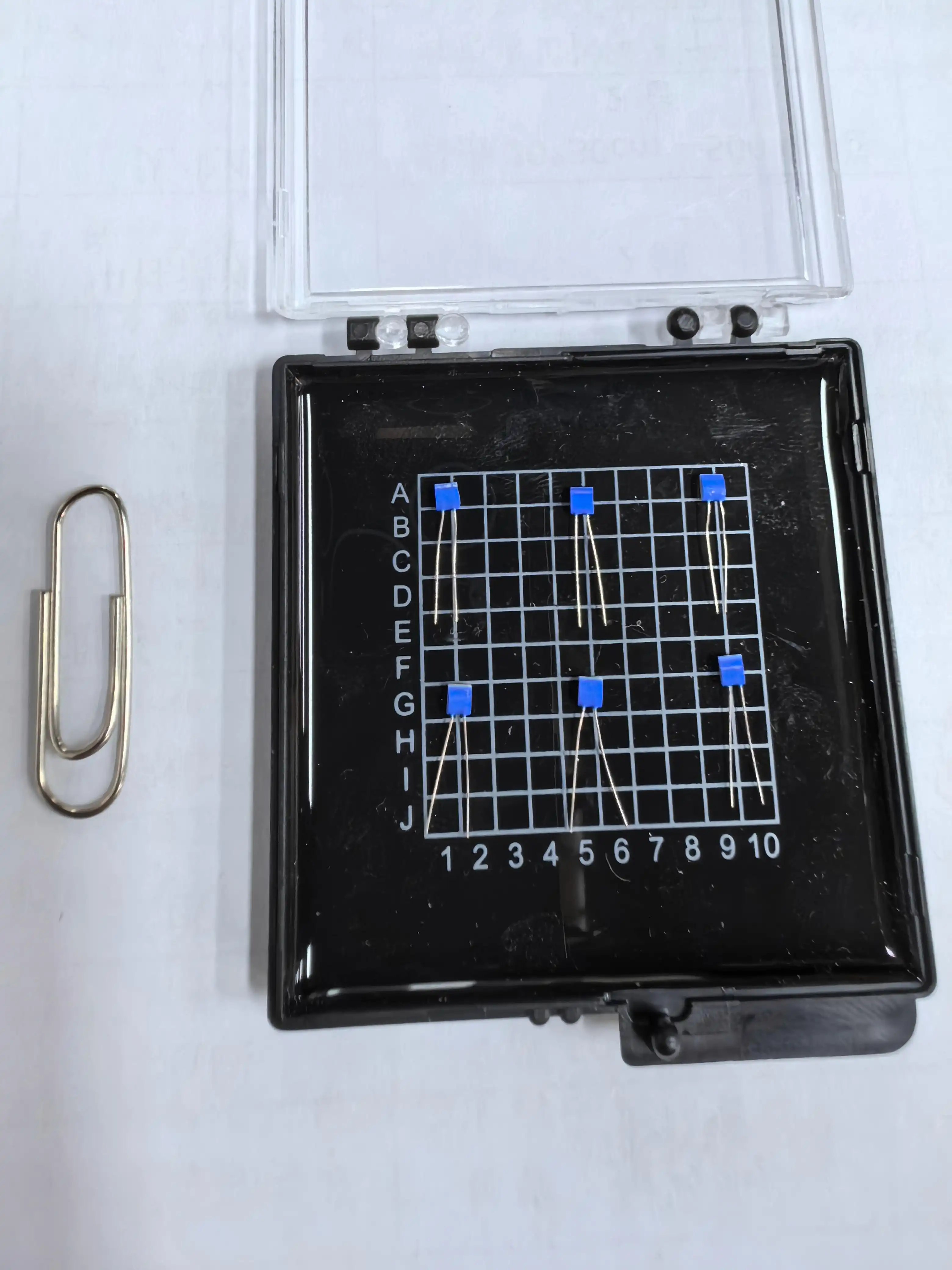

Thermistors are generally less expensive than RTDs, making them attractive for high-volume, cost-sensitive applications. However, the price gap has narrowed with advancements in RTD manufacturing. Size-wise, both can be miniaturized, with some RTDs available in SMD packages as small as 1.2mm, suitable for compact electronic designs.

Conclusion

The choice between RTDs and thermistors depends on balancing factors like accuracy, temperature range, response time, and cost. For applications requiring high precision over a wide temperature range, Pt100 Temperature Sensors are often the go-to choice. Their advanced thin film technology, compliance with standards like IEC60751, and exceptional stability make them ideal for demanding scenarios in industrial, medical, automotive, and aerospace sectors. For expert guidance on selecting the right temperature sensor for your specific needs, don't hesitate to reach out to us at sales11@xatzd.com.

References

1. Baker, B. C. (2018). "Thermistors in Single Supply Temperature Sensing Circuits." Analog Devices Technical Article.

2. Childs, P. R. N., Greenwood, J. R., & Long, C. A. (2000). "Review of temperature measurement." Review of Scientific Instruments, 71(8), 2959-2978.

3. Fraden, J. (2016). "Handbook of Modern Sensors: Physics, Designs, and Applications." Springer International Publishing.

4. McGee, T. D. (1988). "Principles and Methods of Temperature Measurement." John Wiley & Sons.

5. Michalski, L., Eckersdorf, K., Kucharski, J., & McGhee, J. (2001). "Temperature Measurement." John Wiley & Sons.

Learn about our latest products and discounts through SMS or email