- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Why Do Industrial Automation Experts Prefer Platinum Resistance Thermistors?

Why Do Industrial Automation Experts Prefer Platinum Resistance Thermistors?

Industrial automation experts and engineers consistently rank platinum resistance thermistors as the top choice for temperature monitoring. Beyond basic functionality, these sensors offer unique advantages that align with the rigorous demands of modern automation. This article dives into the expert perspective, revealing why platinum resistance thermistors are the gold standard in industrial automation sensing.

Unmatched Precision for Critical Automation Processes

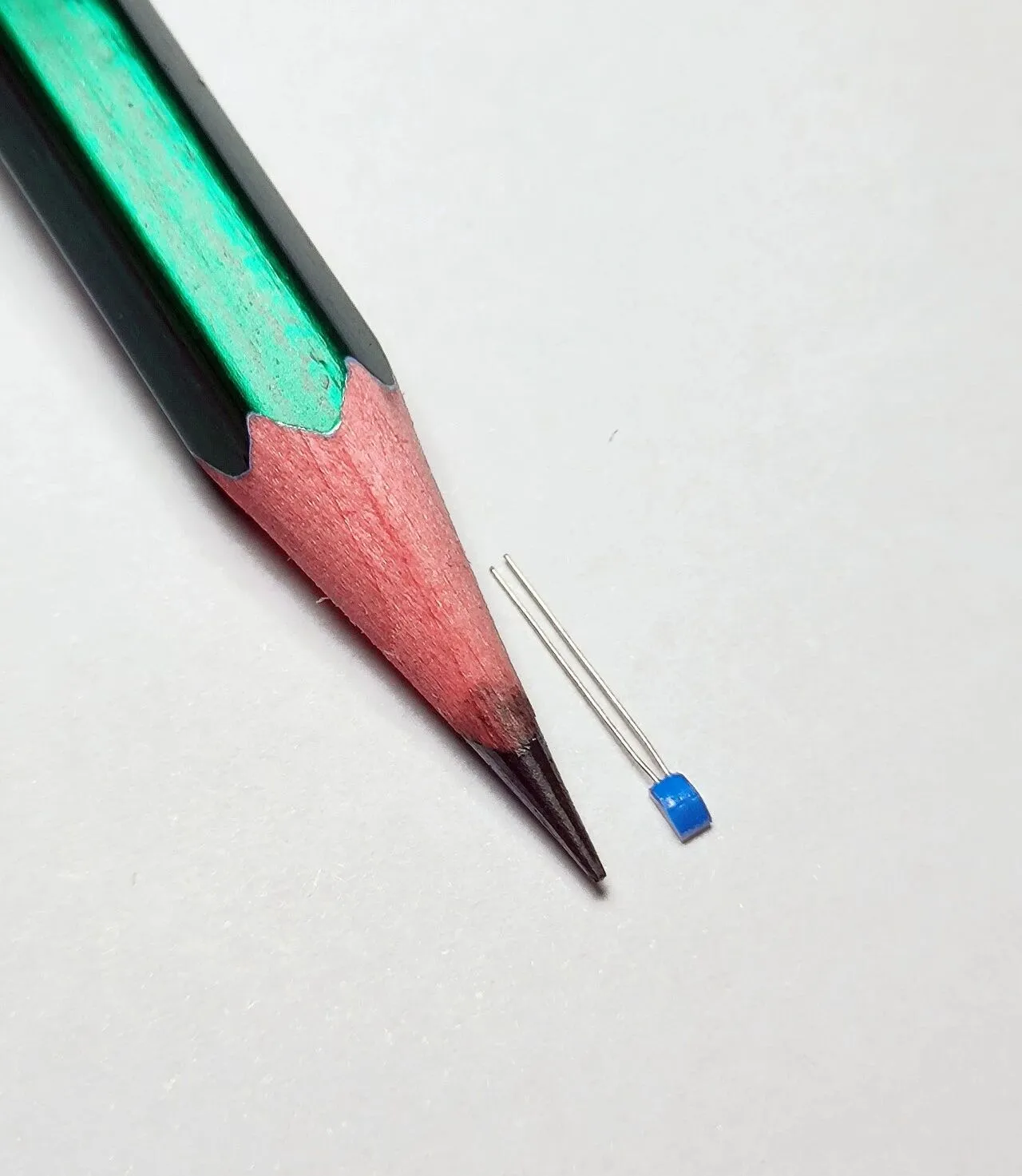

Precision is non-negotiable in industrial automation, and experts prioritize platinum resistance thermistors for their exceptional accuracy. With a 3850 ppm/°C temperature coefficient (TCR) and ±0.1°C accuracy in moderate temperature ranges (20°C-500°C), these sensors deliver consistent readings that other options can’t match. For processes like semiconductor manufacturing or automotive gear heat treatment, even minor temperature deviations can ruin batches or compromise component integrity.

Unlike thermocouples or NTC thermistors, platinum resistance thermistors maintain this precision over time, with ≤±0.04% resistance drift after 1000 hours at 500°C. Automation experts emphasize that this stability eliminates the need for frequent recalibrations, a critical factor for 24/7 operations where downtime is costly.

Durability That Withstands Harsh Automation Environments

1. Vibration and Shock Resistance

Industrial automation facilities are high-stress environments, with conveyor belts, robotic arms, and heavy machinery generating constant vibration and occasional shocks. Platinum resistance thermistors are engineered to survive these conditions, with ≥40g vibration resistance (10–2000 Hz) and ≥100g shock resistance (8 ms half-sine wave). Experts note that cheaper sensors (with ≤20g vibration resistance) fail prematurely in these settings, leading to unplanned downtime.

2. High-Temperature and Corrosion Resistance

Many automation processes involve high temperatures and corrosive substances, and platinum resistance thermistors excel here. They operate reliably up to 500°C, with insulation resistance >2 MΩ at that temperature—ideal for heat treatment or chemical processing. For corrosive environments, optional silver-palladium or pure platinum leads resist degradation, outperforming standard sensors that corrode quickly.

Seamless Integration and Versatility

Automation experts value sensors that integrate easily with existing systems, and platinum resistance thermistors deliver on this front. Their standard lead specifications (10mm length, 0.2mm diameter) and 2-wire/3-wire/4-wire configurations work with most PLCs and automation controllers. Unlike thermocouples, they don’t require a reference junction, simplifying installation and reducing setup costs.

Versatility is another key factor. Platinum resistance thermistors adapt to diverse automation applications—from EV battery thermal management to food processing—with customizable packaging and lead materials. Experts highlight that this flexibility eliminates the need to source multiple sensor types, streamlining supply chains.

FAQ: Expert Insights on Platinum Resistance Thermistors

Q: Do industrial automation experts recommend platinum RTDs for low-temperature applications? A: Yes—they perform reliably down to -50°C, with consistent accuracy for cold storage, refrigeration automation, and cryogenic processes.

Q: What makes platinum resistance thermistors better than smart sensors for some automation tasks? A: They offer simpler integration, lower latency, and higher durability. Smart sensors add connectivity but can be less reliable in harsh environments.

Q: Are platinum resistance thermistors suitable for high-volume automation lines? A: Absolutely—their long lifespan and low maintenance needs make them cost-effective for high-volume production, where sensor replacement is labor-intensive.

Conclusion & CTA

Industrial automation experts preferplatinum resistance thermistors for their unbeatable combination of precision, durability, and versatility. These sensors align with the demands of 24/7 operations, harsh environments, and seamless system integration—critical factors for optimizing automation performance.

If you want to leverage the same sensors trusted by industry experts, contact our team today. We offer expert-backed platinum resistance thermistor solutions tailored to your automation needs, with free technical guidance to ensure optimal integration. Request a sample to test their performance in your facility.

Author Information:

[Liu Bin] is an industrial automation engineer with 15+ years of experience, specializing in sensor technology and process optimization. He collaborates with manufacturers to implement high-reliability sensing solutions.

References:

1. “Industrial Sensor Preferences: Expert Survey 2024” – International Society of Automation (ISA).

2. IEC 60751:2022. Industrial platinum resistance thermometers and platinum temperature sensors.

Xi'an Tongzida Technology Co., Ltd. is a leading manufacturer and supplier of advanced thermistor technology, focusing on providing high-performance temperature sensors for demanding industrial applications. We have profound expertise in microsensor manufacturing, specific packaging technologies, and multi-sensor integration methods, which ensures the excellent performance and reliability of our thermistors. As a trusted supplier of precision temperature measurement solutions, we offer a complete thermistor system, including sensor chips, testing systems, and analysis software. Please feel free to contact our technical experts at any time. ventes11@xatzd.com Discuss your specific requirements for thermistors and learn how our advanced thermal resistor optimization and manufacturing capabilities can enhance the performance and reliability of your temperature measurement system.

Learn about our latest products and discounts through SMS or email