- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Are the Common Applications of Platinum Resistance Thermistors in Industrial Automation?

What Are the Common Applications of Platinum Resistance Thermistors in Industrial Automation?

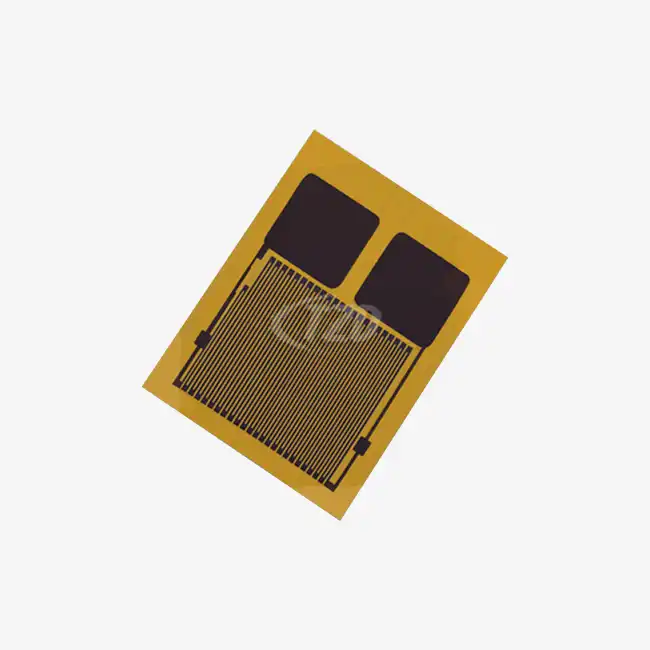

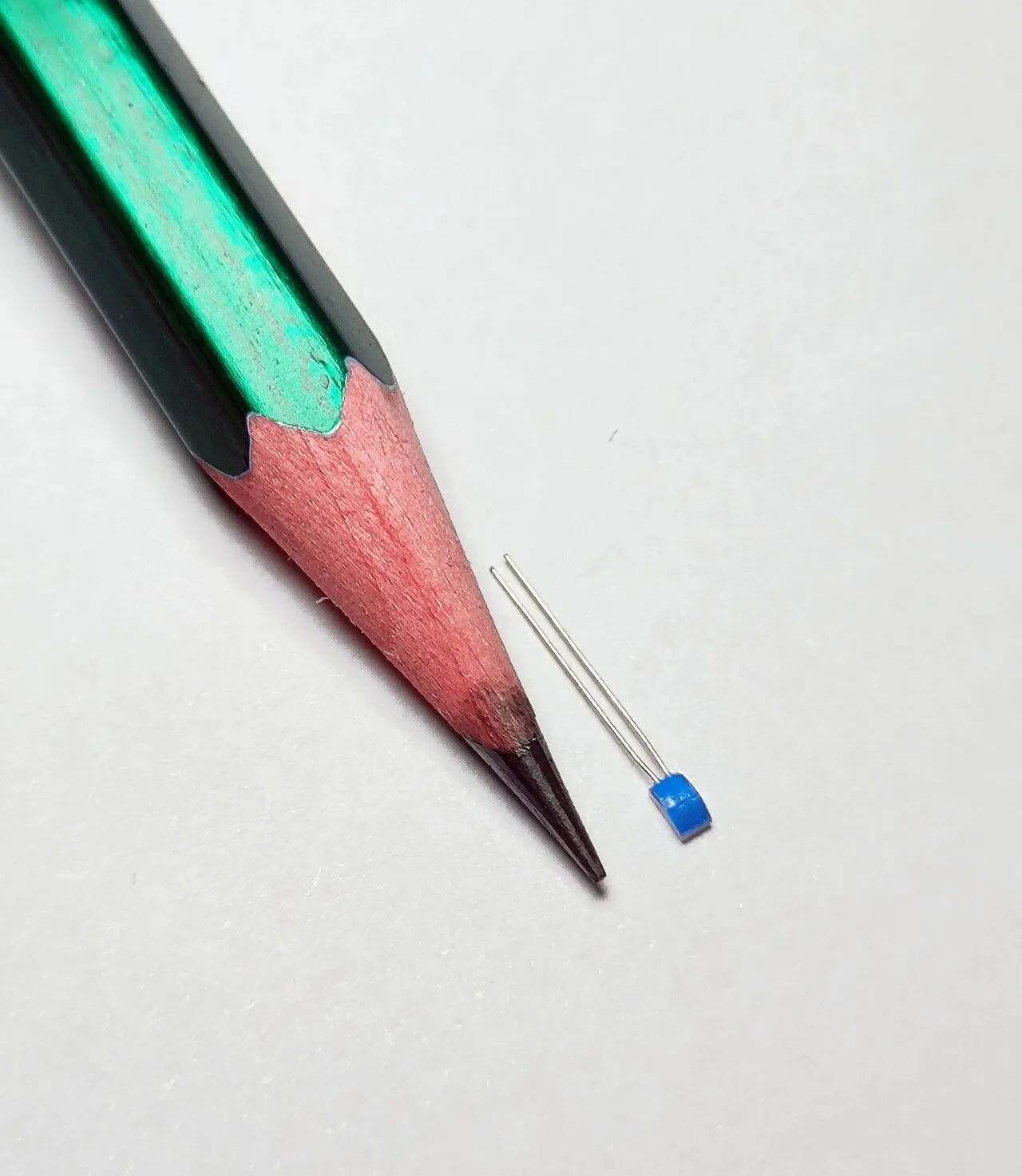

From automotive assembly lines to chemical processing plants, platinum resistance thermistors play a vital role in industrial automation. Their precision, durability, and stability make them suitable for diverse environments—solving real-world temperature monitoring challenges. This article highlights the most common applications and how these sensors add value.

Automotive and Transportation Automation

1. Gear and Transmission Heat Treatment

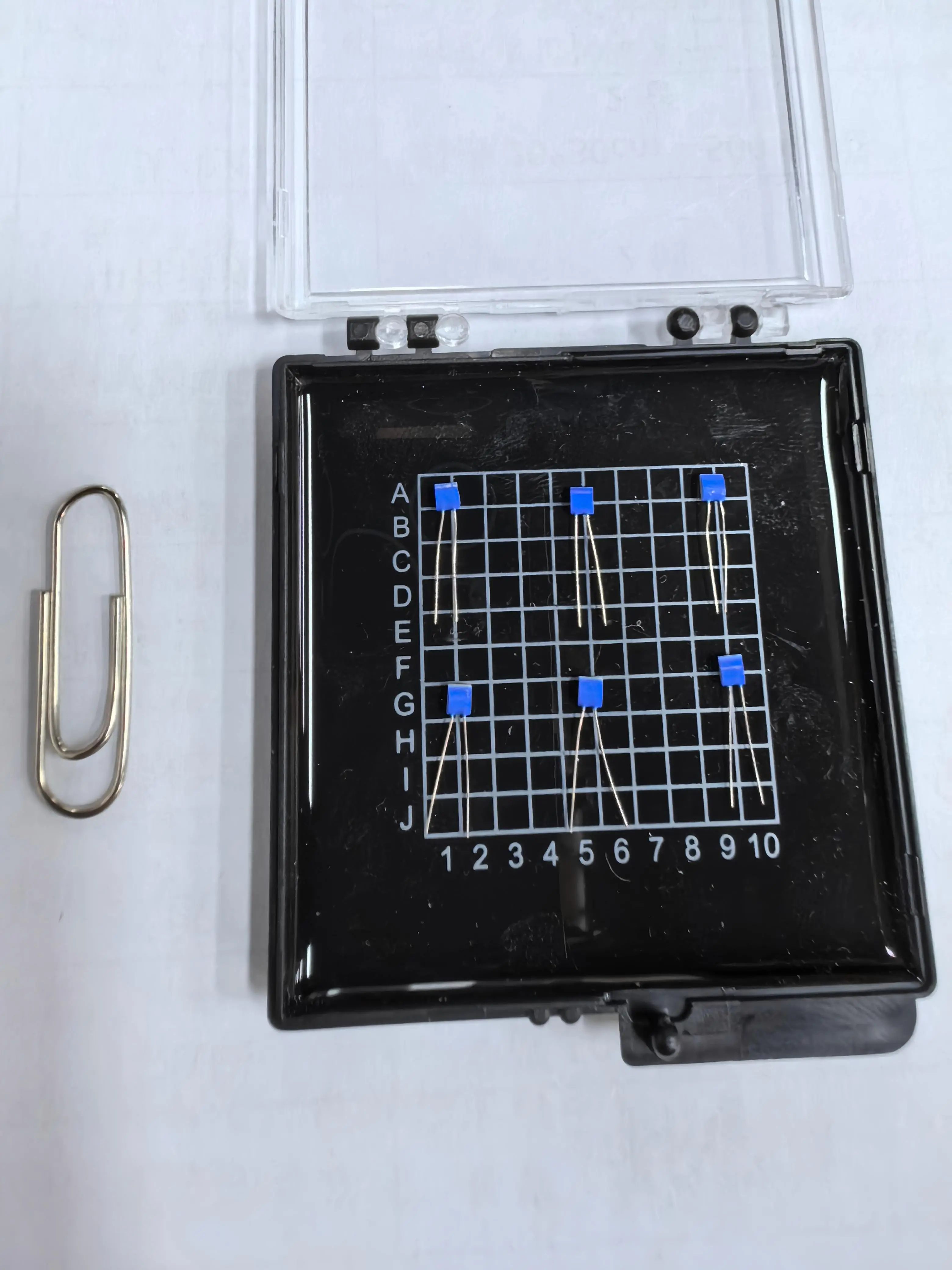

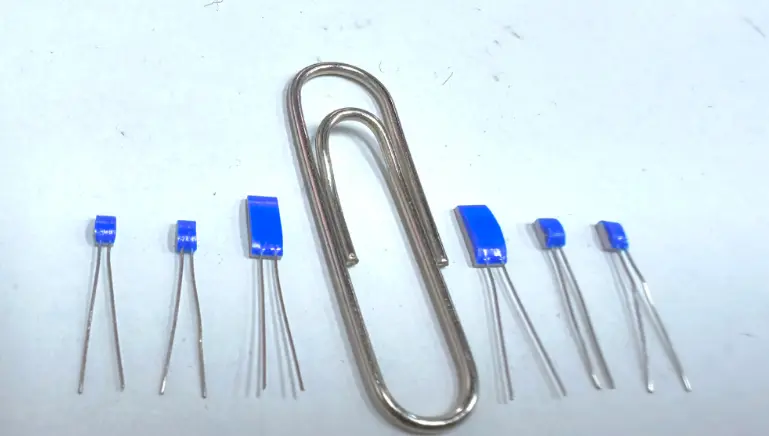

Automotive automation relies on precise temperature control during gear heat treatment (carburizing, induction hardening). platinum resistance thermistors monitor temperatures up to 500°C, with ≤±0.04% resistance drift ensuring consistent gear hardness and fatigue life. Their ≥100g shock resistance withstands the mechanical stress of heat treatment equipment.

2. Battery Pack Thermal Management (EV Automation)

Electric vehicle (EV) battery assembly lines use platinum resistance thermistors to monitor battery pack temperatures during charging, discharging, and assembly. The 3850 ppm/°C TCR ensures accurate readings, preventing overheating and battery degradation. Their low self-heating (0.4°C/mW) avoids skewing readings in the confined battery pack space.

Food and Beverage Automation

Food processing automation requires strict temperature control to meet safety standards (e.g., FDA, EU Food Safety Authority).platinum resistance thermistors monitor temperatures in pasteurization, baking, and cold storage processes. Their accuracy (±0.1°C) ensures food is cooked or cooled to safe levels, while their durable construction resists cleaning chemicals and moisture.

In cold storage automation (-20°C to 10°C), platinum resistance thermistors maintain precision, avoiding spoilage from temperature fluctuations. Their fast response time (t₀.₉=10s in airflow) triggers HVAC adjustments quickly, preserving food quality.

Chemical and Pharmaceutical Automation

Chemical and pharmaceutical automation involves corrosive environments, high temperatures, and strict compliance (GMP, ISO). platinum resistance thermistors with silver-palladium leads resist corrosion from acids and solvents, while their insulation resistance (>2 MΩ at 500°C) ensures safety in high-heat reactions.

In pharmaceutical manufacturing, these sensors monitor temperature in reactor vessels and sterilization equipment, ensuring consistent drug formulation and compliance. Their long-term stability eliminates the risk of inaccurate readings that could lead to batch failures.

Robotics and Industrial Machinery Automation

Automated robots and machinery generate heat during operation, which can damage components and reduce lifespan. platinum resistance thermistors are placed in robot joints, motors, and control units to monitor temperature, triggering cooling systems when needed. Their ≥40g vibration resistance withstands robotic movement, while fast response time ensures timely cooling.

FAQ: Applications of Platinum Resistance Thermistors

Q: Can platinum resistance thermistors be used in wet automation environments? A: Yes—with custom waterproof packaging, they’re suitable for wet applications like food washing lines or chemical mixing tanks.

Q: Are platinum resistance thermistors compatible with cleanroom automation? A: Absolutely. Their vacuum plastic packaging (or custom cleanroom-grade packaging) meets ISO 14644 cleanroom standards.

Q: For high-pressure automation processes, do platinum RTDs work? A: Yes—we offer铠装 (sheathed) models that withstand high pressure (up to 1000 bar), ideal for oil and gas automation.

Conclusion & CTA

From automotive heat treatment to pharmaceutical manufacturing, platinum resistance thermistors are versatile workhorses in industrial automation. Their precision, durability, and adaptability make them suitable for the most demanding environments, solving critical temperature monitoring challenges.

If you’re looking for a sensor tailored to your specific automation application, our team can help. We offer custom platinum resistance thermistors for automotive, food, chemical, and robotics automation. Contact us today to share your application details and request a free datasheet.

Author Information: [Zhang Fei] is an industrial automation applications specialist, with experience in sensor integration across diverse industries. He helps manufacturers leverage temperature sensors to meet compliance and performance goals.

References:

1. “Temperature Monitoring in Automotive Automation” – Automotive Engineering International, 2024.

2. ISO 22000:2018. Food Safety Management Systems for Food Manufacturing.

Xi'an Tongzida Technology Co., Ltd. is a leading manufacturer and supplier of advanced thermistor technology, focusing on providing high-performance temperature sensors for demanding industrial applications. We have profound expertise in microsensor manufacturing, specific packaging technologies, and multi-sensor integration methods, which ensures the excellent performance and reliability of our thermistors. As a trusted supplier of precision temperature measurement solutions, we offer a complete thermistor system, including sensor chips, testing systems, and analysis software. Please feel free to contact our technical experts at any time. ventes11@xatzd.com Discuss your specific requirements for thermistors and learn how our advanced thermal resistor optimization and manufacturing capabilities can enhance the performance and reliability of your temperature measurement system.

Learn about our latest products and discounts through SMS or email