Comprehending the Pt300 Thin Film Sensor Technology

The Composition and Structure of Pt300 Thin Film Sensors

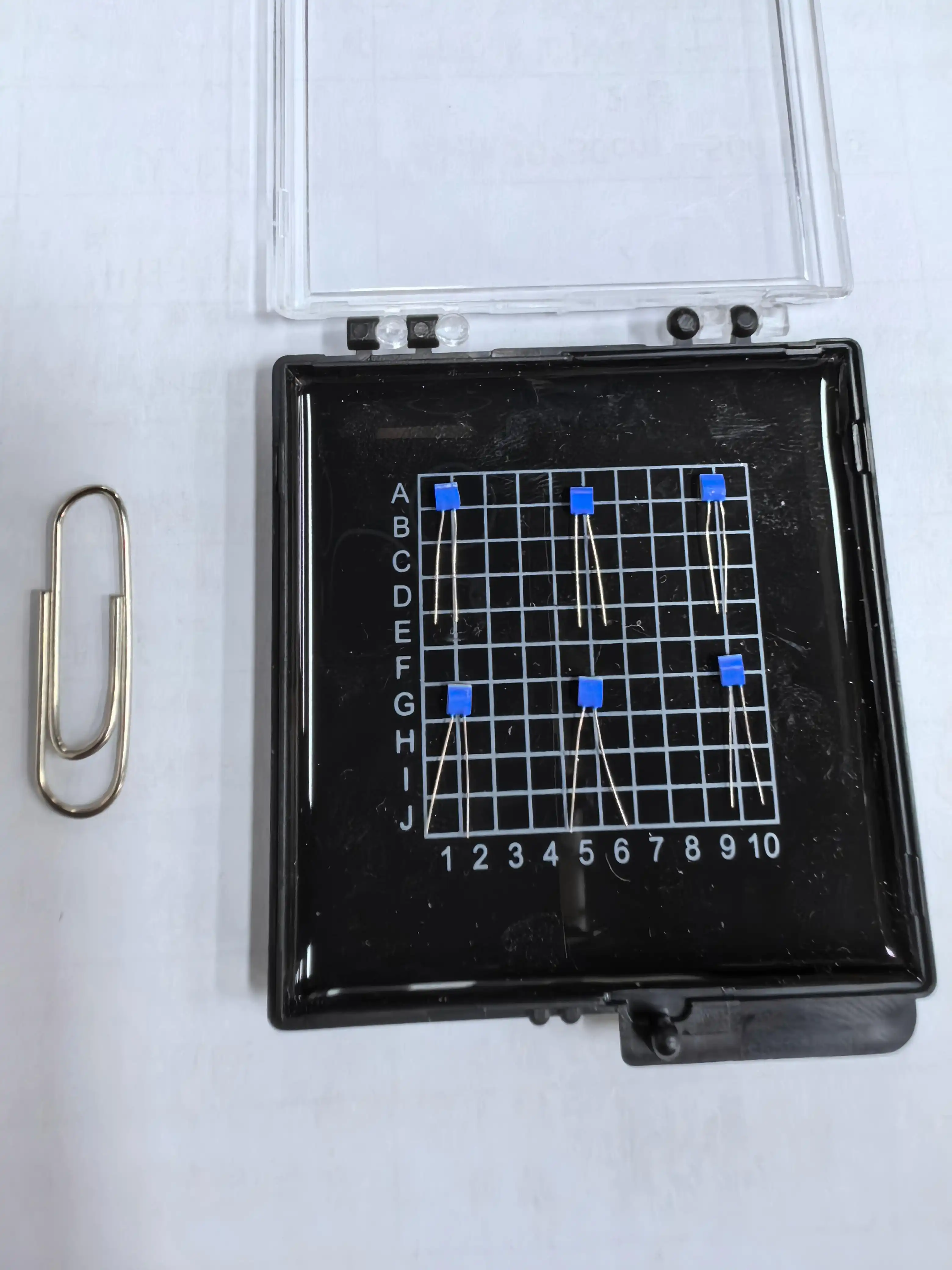

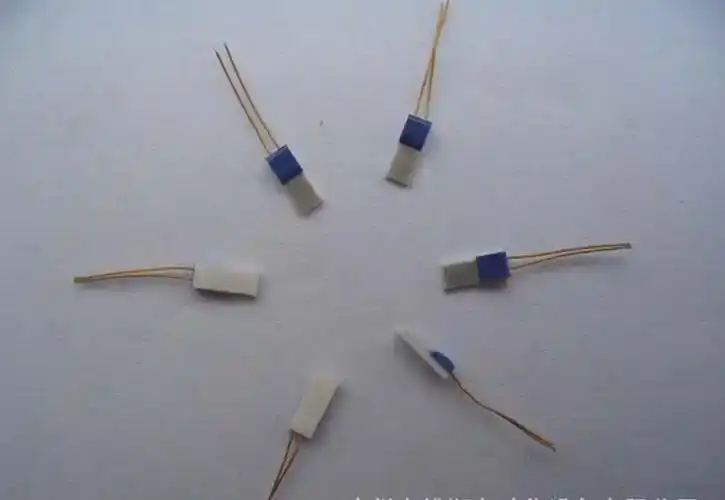

Pt300 thin film sensors are meticulously crafted using advanced thin-film deposition techniques. These sensors typically consist of a platinum resistance element deposited on a ceramic substrate, with dimensions as compact as 2.0mm x 3.0mm x 1.0mm. The platinum layer, often just a few micrometers thick, is precisely patterned to achieve the desired resistance characteristics.

The sensor's leads, usually made of platinum-nickel wire with a diameter of 0.2 mm and a length of 10 mm, provide robust electrical connections. These leads boast a tensile strength of ≥9 N, ensuring durability in various applications. Alternative lead materials such as silver-palladium, pure platinum, or pure silver are available to suit specific requirements.

Operating Principles and Performance Characteristics

Pt300 thin film sensors operate on the principle of temperature-dependent electrical resistance. As the temperature changes, the resistance of the platinum element varies linearly, allowing for precise temperature measurements. The temperature coefficient of resistance (TCR) for these sensors is typically 3850 ppm/°C, complying with the IEC60751 standard.

These sensors exhibit impressive performance characteristics, including:

- High insulation resistance: 100 MΩ at 20°C and >2 MΩ at 500°C

- Exceptional long-term stability: ≤±0.04% resistance drift of R₀ (0°C reference) after 1000 hours at 500°C

- Quick response times: In water flow (V=0.4 m/s), t₀.₅ = 0.05 s and t₀.₉ = 0.15 s; in airflow (V=2 m/s), t₀.₅ = 3 s and t₀.₉ = 10 s

- Low self-heating coefficient: 0.4°C/mW (at 0°C)

- High vibration resistance: ≥40g acceleration (frequency range: 10–2000 Hz)

- Excellent shock resistance: ≥100g acceleration (8 ms half-sine wave)

Key Advantages of Pt300 Thin Film Sensors in Various Applications

Precision and Accuracy in Temperature Measurement

One of the primary advantages of Pt300 thin film sensors is their exceptional precision and accuracy in temperature measurement. With an accuracy of ± 0.01 Ω, these sensors provide highly reliable temperature readings across a wide range of -200°C to +850°C. This level of precision is crucial in applications where even slight temperature variations can have significant consequences, such as in semiconductor manufacturing, pharmaceutical processes, or aerospace systems.

The high temperature coefficient of resistance (3850 ppm/°C) ensures that Pt300 thin film sensors are highly sensitive to temperature changes, allowing for the detection of minute fluctuations. This sensitivity, combined with their linear response, makes them ideal for applications requiring precise temperature control or monitoring.

Rapid Response and Dynamic Performance

Pt300 thin film sensors excel in applications that demand quick response to temperature changes. Their rapid response times, particularly in liquid environments (t₀.₅ = 0.05 s in water flow), make them suitable for real-time temperature monitoring and control systems. This quick response is invaluable in processes where temperature needs to be adjusted rapidly, such as in chemical reactors or heat treatment processes.

The dynamic performance of these sensors is further enhanced by their low thermal mass, which minimizes the sensor's impact on the temperature of the medium being measured. This characteristic is particularly beneficial in applications involving small volumes or rapid temperature fluctuations, such as in microfluidic devices or fast-moving production lines.

Durability and Reliability in Harsh Environments

Pt300 thin film sensors are engineered to withstand challenging environmental conditions, making them highly reliable in industrial and high-stress applications. Their robust construction, featuring a ceramic substrate and protective encapsulation, contributes to their durability and long-term stability.

The sensors' high vibration resistance (≥40g acceleration) and shock resistance (≥100g acceleration) make them suitable for use in environments with significant mechanical stress, such as automotive engines, aircraft systems, or industrial machinery. This resilience ensures consistent performance and reduces the need for frequent sensor replacements, leading to lower maintenance costs and improved system reliability.

Furthermore, the excellent long-term stability of Pt300 thin film sensors, with a resistance drift of ≤±0.04% after 1000 hours at 500°C, ensures that they maintain their accuracy over extended periods. This stability is crucial in applications requiring continuous, long-term temperature monitoring, such as in process control systems or environmental monitoring stations.

Innovations and Future Prospects in Pt300 Thin Film Sensor Technology

Advancements in Fabrication and Materials

The field of Pt300 thin film sensor technology is witnessing continuous advancements in fabrication techniques and materials. Manufacturers are exploring new deposition methods to create even thinner and more uniform platinum films, potentially improving sensor sensitivity and response times. Novel substrate materials are also being investigated to enhance thermal properties and expand the operating temperature range of these sensors.

Innovations in lead materials and attachment techniques are aimed at improving the overall robustness of the sensors. The development of new alloys and composite materials for leads could further enhance the sensors' resistance to corrosion and fatigue, extending their lifespan in harsh environments.

Integration with IoT and Smart Systems

The future of Pt300 thin film sensors lies in their integration with Internet of Things (IoT) technologies and smart systems. Miniaturization efforts are focused on creating smaller sensors that can be easily incorporated into compact devices and wearable technology. This miniaturization, coupled with improvements in low-power operation, is paving the way for battery-operated and energy-harvesting temperature sensing solutions.

Advanced packaging techniques are being developed to enhance the sensors' compatibility with wireless communication modules. This integration enables real-time temperature data transmission to cloud-based platforms, facilitating remote monitoring and predictive maintenance in industrial settings. The combination of Pt300 thin film sensors with artificial intelligence and machine learning algorithms is opening new possibilities for intelligent temperature control systems and predictive analytics in various industries.

Expanding Applications in Emerging Fields

As technology continues to evolve, Pt300 thin film sensors are finding new applications in emerging fields. In the biomedical sector, these sensors are being adapted for use in minimally invasive medical devices and implantable temperature monitors. Their small size and biocompatibility make them ideal for such applications.

In the realm of renewable energy, Pt300 thin film sensors are playing a crucial role in optimizing the efficiency of solar panels and wind turbines. Their ability to provide accurate temperature measurements in harsh outdoor conditions is essential for maintaining optimal performance of these systems.

The automotive industry is also leveraging the advantages of Pt300 thin film sensors in the development of electric and autonomous vehicles. These sensors are crucial for battery temperature management, motor performance optimization, and ensuring the safe operation of various vehicle systems.

Conclusion

Pt300 thin film sensors offer a multitude of advantages that make them indispensable in various high-precision temperature measurement applications. Their exceptional accuracy, rapid response times, and remarkable stability across a wide temperature range make them ideal for demanding environments in industrial, medical, automotive, and aerospace sectors. As technology continues to advance, these sensors are poised to play an even more significant role in shaping the future of temperature sensing and control systems. For more information about our Pt300 thin film sensors and their applications, please contact us at sales11@xatzd.com.