- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

medical robot joint flexible temperature sensor

Intelligent dressing wound temperature measurement, why do flexible sensors better understand healing needs?

In the robotic arm joints of surgical robots and the active joints of rehabilitation robots, the flexible temperature sensors of medical robot joints are solving the problem of overheating and shutdown caused by the detachment of traditional rigid sensors due to their "dynamic fit+anti friction" characteristics

H2: Two traditional challenges in joint temperature measurement for medical robots

H3: Rigid sensors (≥ 10 × 8mm) cannot bend with the joint surface, and the detachment rate during motion reaches 30%+

H3: High frequency friction heating (local temperature rise>50 ℃ when joint speed>500rpm), traditional sensor temperature drift exceeds ± 1 ℃ (false alarm shutdown)

H2: Joint scene adaptability of flexible sensors

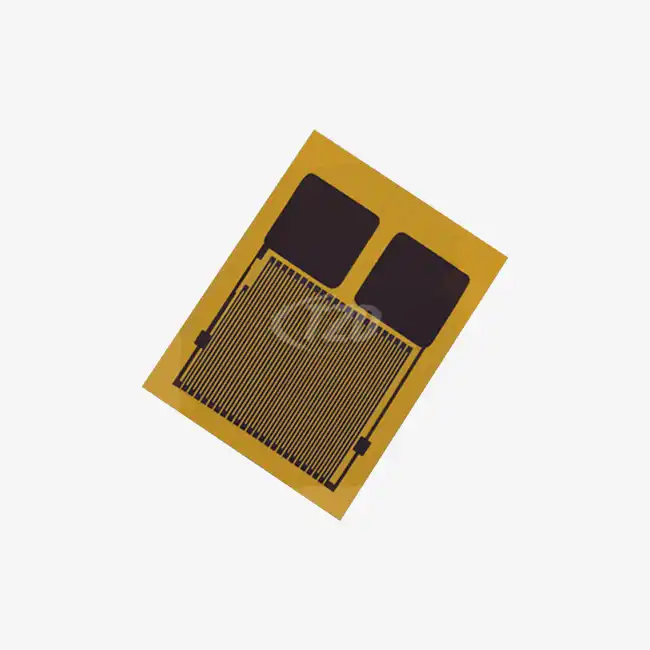

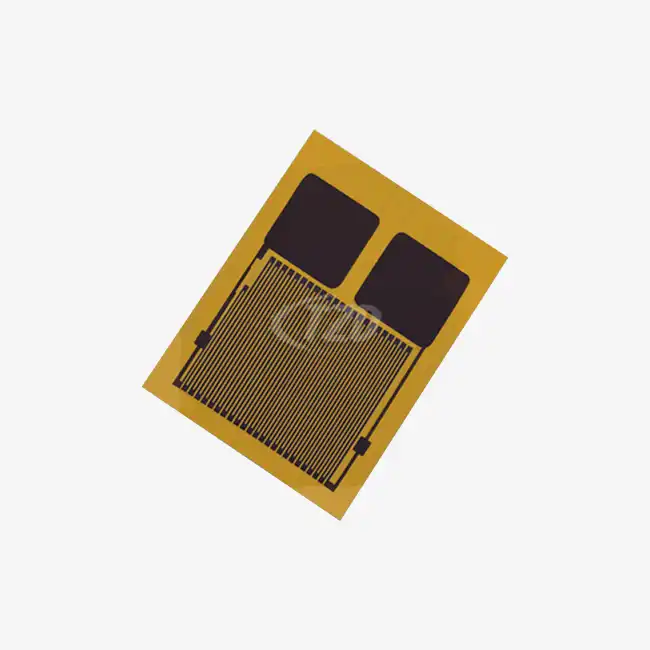

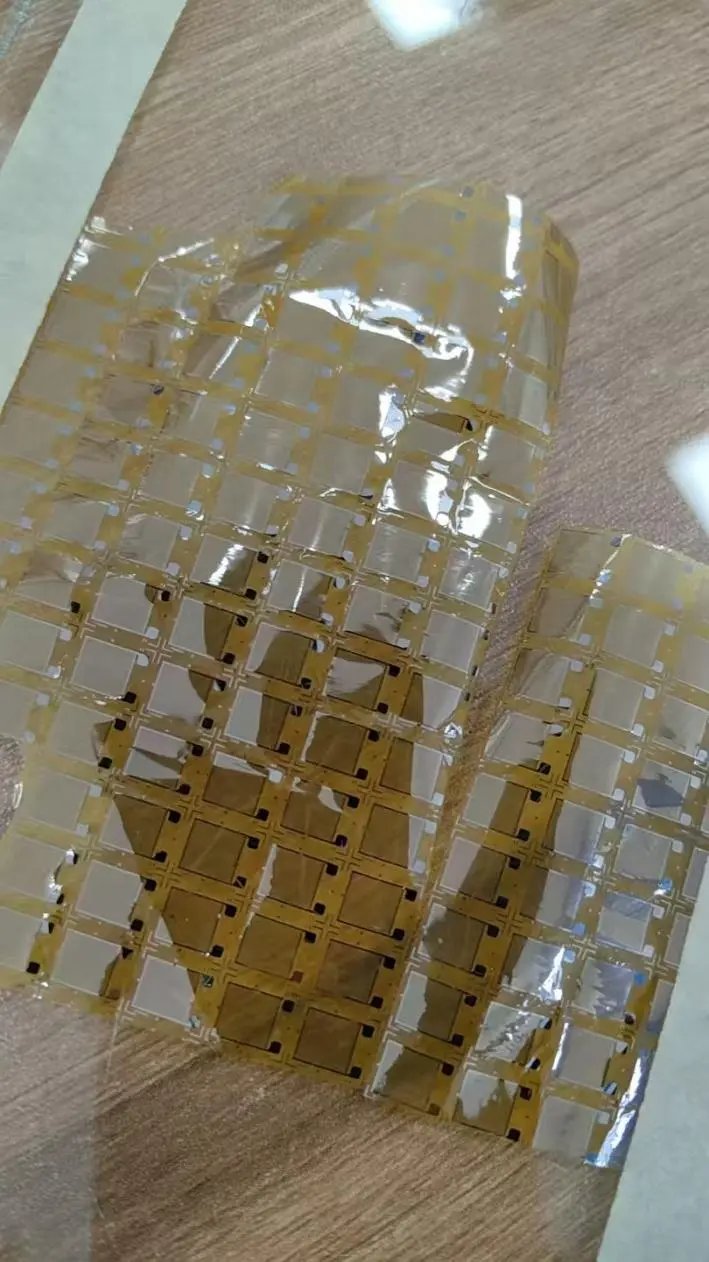

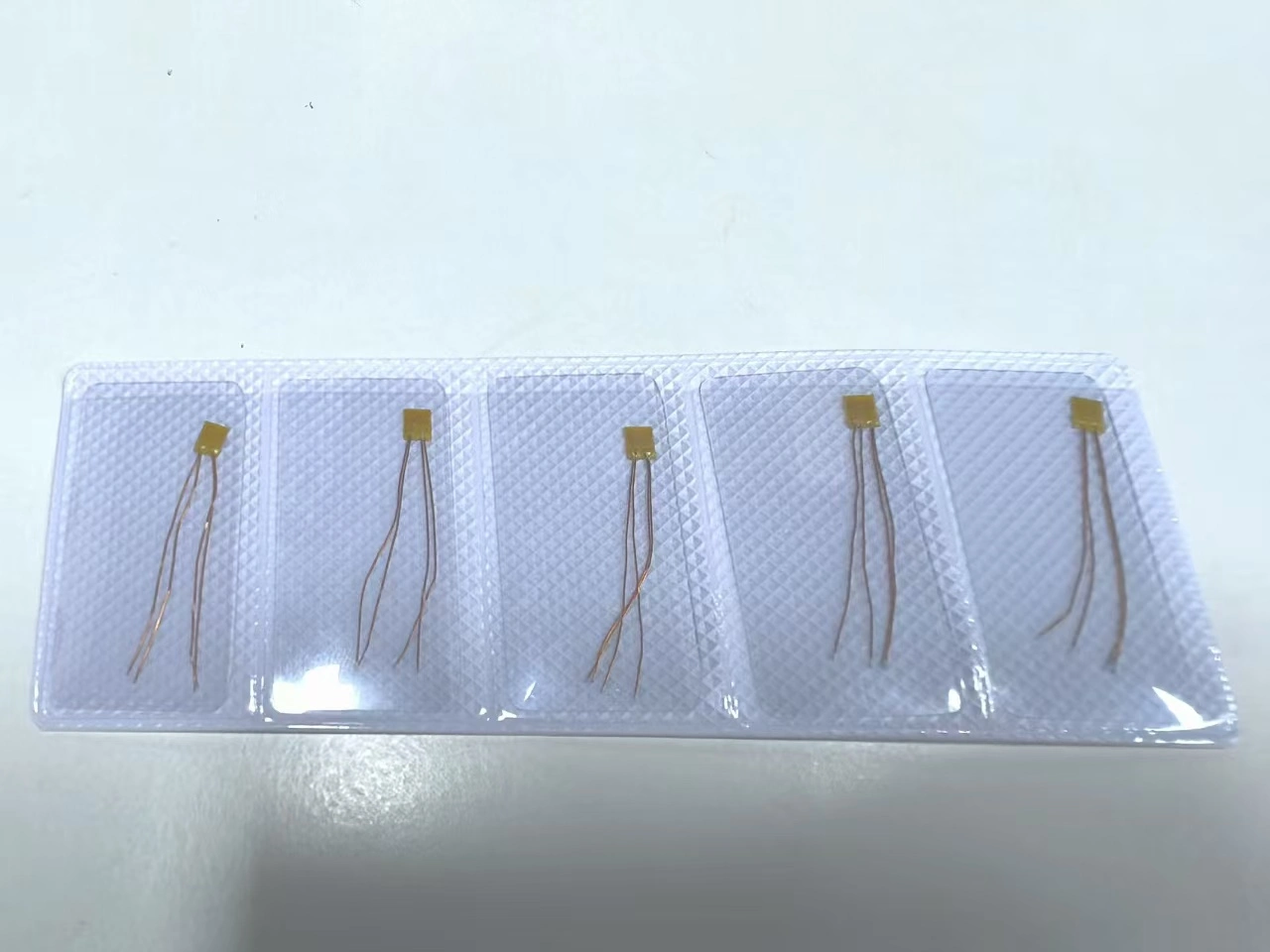

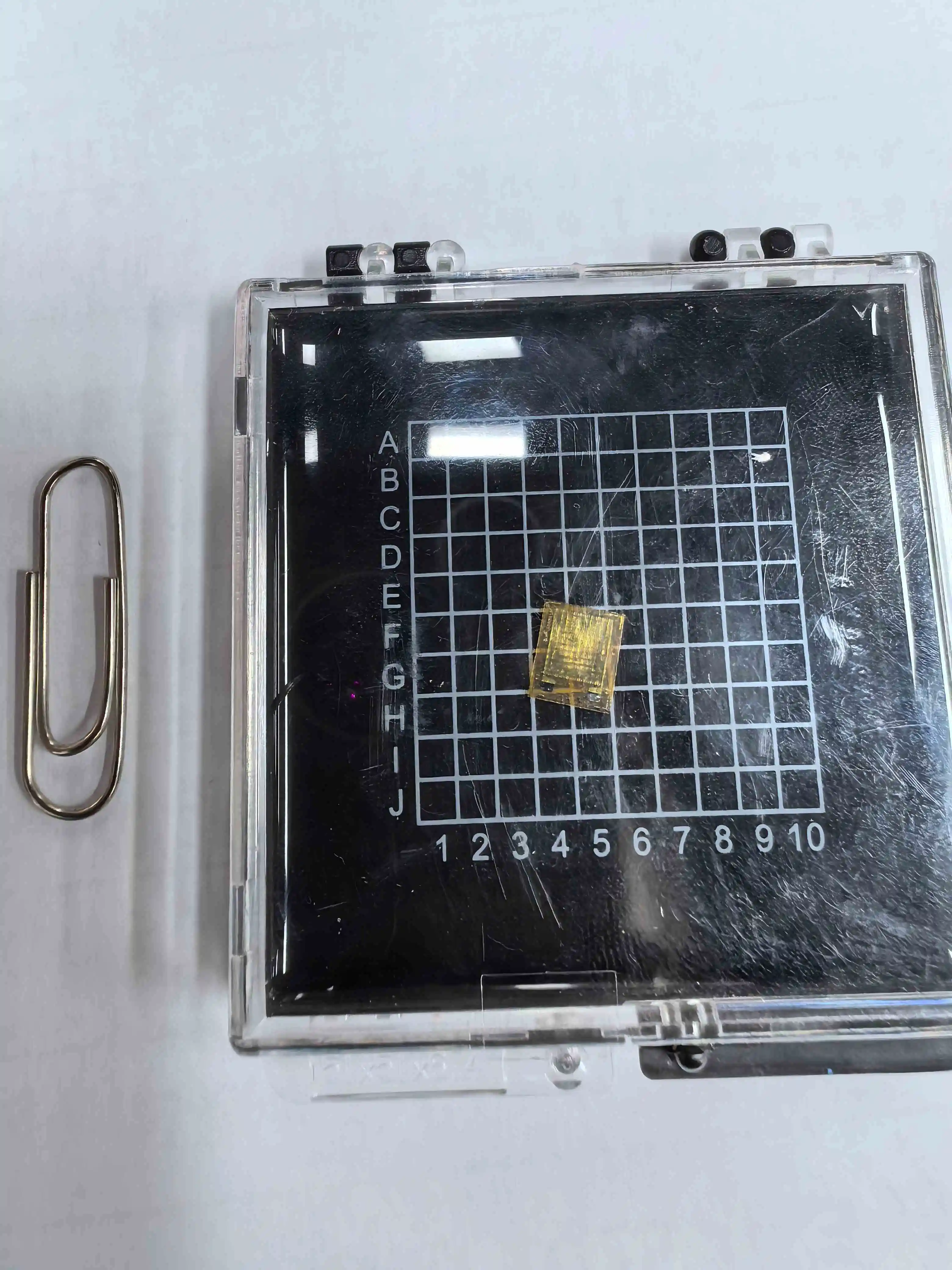

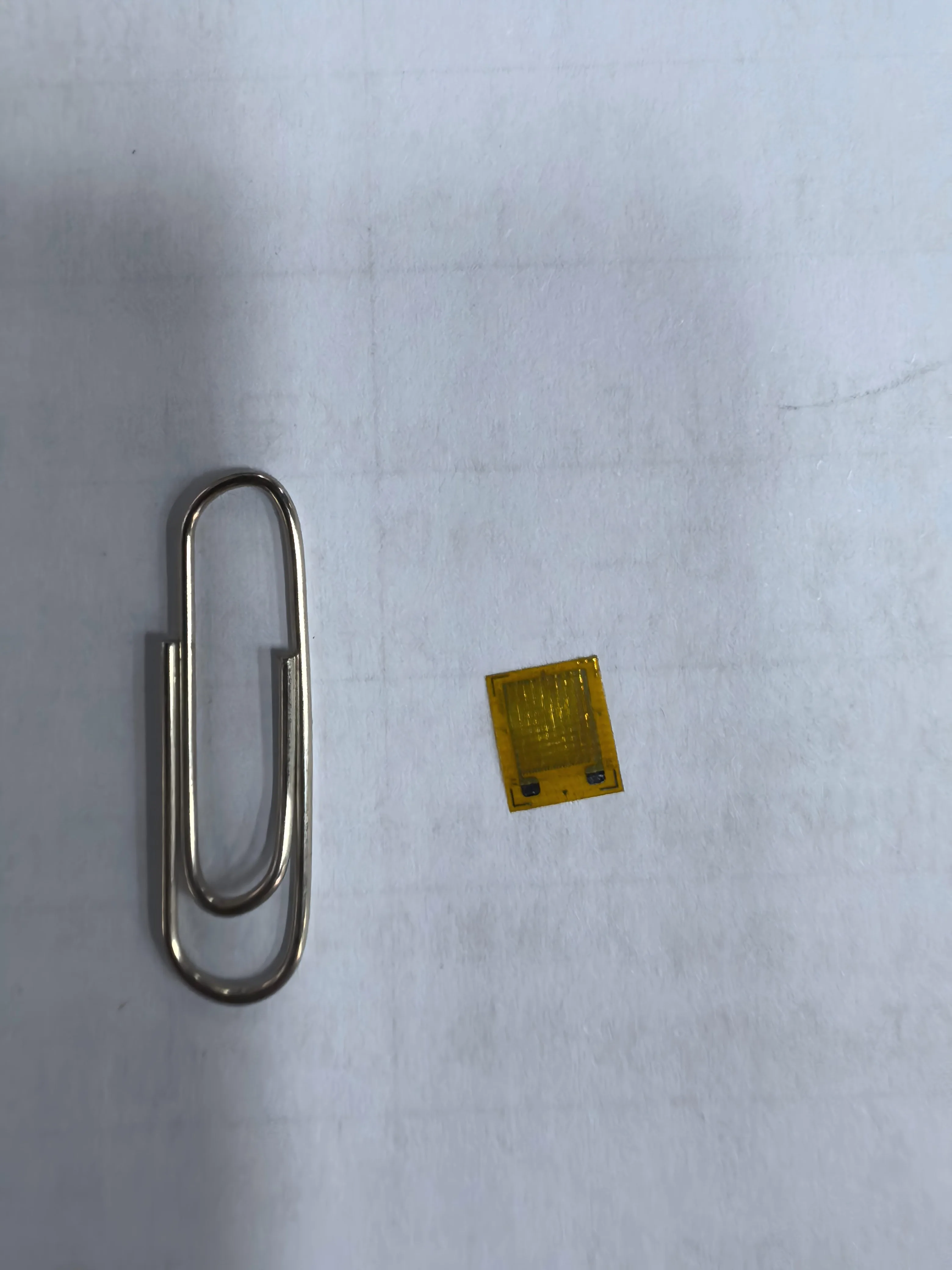

Our medical robot joint flexible temperature sensor is only 6 × 4 × 0.05mm, designed with a serpentine wire that can bend 360 ° with the joint (curvature radius ≥ 5mm), and has a measured detachment rate of 0 after 100000 movements.

H3: Anti friction heating: wide temperature range of -70~200 ℃ covering extreme joint working conditions, TCR 6444ppm/℃ low drift (accuracy maintained at ± 0.6 ℃);

After being used by a certain surgical robot manufacturer, the number of joint overheating false alarms decreased from an average of 12 times per month to 0, and the equipment utilization rate increased by 25%. This is precisely the value of the flexible temperature sensor for medical robot joints.

H3: Easy to integrate: gold-plated solder pads (anti-oxidation) directly connected to robot control system, without the need for additional fixed structures.

H2: Practical Case: Minimally Invasive Medical Robot Joint Monitoring Project

Scenario: Minimally invasive "Tumai" laparoscopic surgical robot (joint speed 600rpm, curved surface curvature radius 8mm)

Solution: Customized 6 × 4mm flexible sensor (attached to the inner side of the joint bearing)+wireless transmission module (size increase ≤ 3mm)

Effect: Real time monitoring of joint temperature (35-80 ℃), overheating warning response time<0.5 seconds, and a 40% reduction in postoperative equipment maintenance costs.

H2: Selection guide: 4 key indicators of joint sensors for medical robots

Bending life (≥ 100000 cycles, refer to ISO 22653 standard)

Anti electromagnetic interference (EMC certification to avoid interference from robot motor signals)

Response speed (≤ 1 second, matching high-speed joint movement)

Certification (ISO 13485 Medical Quality Management System+CE Certification for Robotics Industry)

References (3):

Technical Specification for Joint Thermal Management of Medical Robots (China Robot Industry Alliance, 2023)

Minimally Invasive Medical Robot Project Test Report (2024)

SGS Flexible Sensor Bending Fatigue Test Certification (Report No. SH-SGS-202406)

Say goodbye to joint overheating shutdown and maintenance costs, the flexible temperature sensor of medical robot joints is the "invisible guardian" of the stability of medical robots. Apply for samples immediately and obtain the same minimally invasive solution!

Author Information: Mr. Chen | Expert in Medical Robot Sensor Applications (12 years of experience in robot thermal management research and development, leading 3 surgical robot sensor projects)

FAQ (3 questions):

Q1: Can the sensor withstand chemical corrosion from joint lubricating oil?

A: Support customized oil resistant coatings (such as fluororubber), which have passed the compatibility test of lubricating oil for minimally invasive medical robots.

Q2: What is the delivery cycle for bulk procurement?

A: Regular orders can be delivered within 15 days, urgent orders can be expedited within 7 days (air freight is supported).

Q3: Do you provide joint temperature data analysis software?

A: Support API docking with robot control systems.

Xi'an Tongzida Technology Co., Ltd. is a leading manufacturer and supplier of advanced thermistor technology, dedicated to providing high-performance temperature sensors for demanding industrial applications. We have comprehensive expertise in microsensor manufacturing technology, special packaging technology, and multi-sensor integration methods to ensure excellent performance and reliability of thermistors. As a trusted supplier of precision temperature measurement solutions, we offer a complete thermistor system, including core sensitive chips, testing systems, and analysis software. Please contact our technical experts sales11@xatzd.com Discuss your specific thermistor requirements and learn how our advanced resistor temperature optimization and manufacturing capabilities can improve the performance and reliability of your temperature measurement system.

Learn about our latest products and discounts through SMS or email