Understanding the Fundamentals of Thin Film Pt100 Sensors

The Technology Behind Thin Film Pt100

Thin Film Pt100 sensors represent a significant advancement in temperature measurement technology. These sensors are fabricated using precision deposition techniques, where a thin layer of platinum is applied to a ceramic substrate. This process results in a compact, robust sensor with excellent thermal properties. The platinum layer, typically only a few micrometers thick, is precisely patterned to achieve the desired resistance characteristics.

One of the key advantages of Thin Film Pt100 sensors is their adherence to international standards. For instance, they comply with the IEC60751 standard, ensuring consistent performance across different manufacturers. The temperature coefficient of resistance (TCR) for these sensors is typically 3850 ppm/°C, which provides high sensitivity and accuracy in temperature measurements.

Key Features and Specifications

Thin Film Pt100 sensors boast impressive specifications that contribute to their superior performance. Let's examine some of these key features:

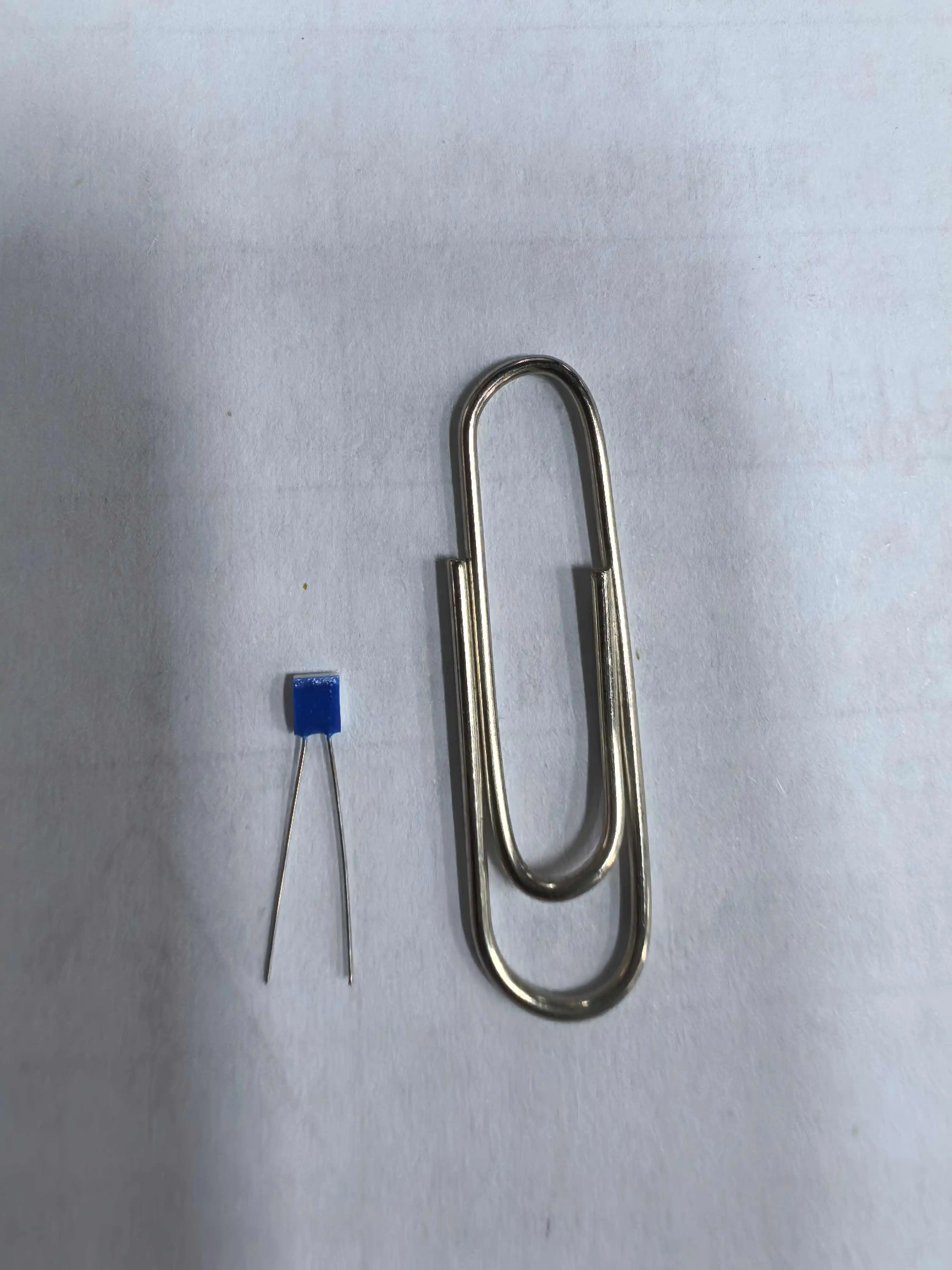

- Compact Size: With dimensions as small as 3.2mm x 1.6mm x 0.7mm, these sensors can be integrated into tight spaces without compromising performance.

- Wide Temperature Range: They can measure temperatures from -50°C to +200°C, with some advanced models capable of operating from -200°C to +850°C.

- High Accuracy: These sensors offer exceptional accuracy, with some models achieving ±0.01 Ω precision.

- Excellent Stability: Long-term stability is a hallmark of Thin Film Pt100 sensors, with resistance drift as low as ±0.06% after 1000 hours at 200°C.

- Fast Response Time: With response times as quick as 0.05 seconds, these sensors can capture rapid temperature changes effectively.

- Robust Construction: They offer high vibration resistance (up to 40g) and impact resistance (up to 100g), making them suitable for harsh industrial environments.

Comparing Thin Film and Wire Wound Pt100 Sensors

Performance in Extreme Conditions

When it comes to performance in extreme conditions, both Thin Film and Wire Wound Pt100 sensors have their strengths. Wire Wound sensors traditionally held an advantage in very high-temperature applications, but advancements in Thin Film technology have narrowed this gap significantly.

Thin Film Pt100 sensors excel in environments with high vibration and mechanical stress. Their compact, solid-state construction makes them more resistant to physical shocks and vibrations compared to Wire Wound sensors. This robustness is particularly valuable in automotive and aerospace applications, where sensors must withstand constant motion and varying G-forces.

In terms of low-temperature performance, Thin Film sensors often have the edge. Their design allows for more consistent performance at cryogenic temperatures, making them ideal for applications in scientific research and specialized industrial processes.

Response Time and Accuracy

One area where Thin Film Pt100 sensors clearly outperform their Wire Wound counterparts is in response time. The thin layer of platinum in these sensors allows for rapid heat transfer, resulting in response times as low as 0.05 seconds. This quick response is crucial in processes that require immediate temperature feedback or in safety-critical applications where even a slight delay could have significant consequences.

In terms of accuracy, both types of sensors can achieve high levels of precision. However, Thin Film Pt100 sensors often have an advantage due to their manufacturing process, which allows for tighter control over the sensor's characteristics. With accuracies of ±0.01 Ω achievable, Thin Film sensors are particularly well-suited for applications requiring extremely precise temperature measurements.

Long-term Stability and Drift

Long-term stability is a critical factor in many industrial applications, and here, Thin Film Pt100 sensors shine. These sensors exhibit minimal drift over time, even when exposed to high temperatures for extended periods. For instance, some Thin Film Pt100 sensors show a resistance drift of ≤±0.06% after 1000 hours at 200°C. This stability ensures reliable measurements over the sensor's lifetime, reducing the need for frequent recalibration.

Wire Wound sensors, while generally stable, can be more susceptible to mechanical stresses over time. The wound wire construction may experience slight shifts or expansions, potentially affecting the sensor's accuracy over long periods. In contrast, the solid-state nature of Thin Film sensors makes them inherently more stable under various environmental conditions.

Applications and Industry-Specific Advantages of Thin Film Pt100

Industrial and Manufacturing Uses

In industrial and manufacturing settings, Thin Film Pt100 sensors have become increasingly prevalent due to their robust performance and versatility. These sensors are particularly valuable in processes that require precise temperature control, such as semiconductor manufacturing, where even minor temperature fluctuations can significantly impact product quality.

The compact size of Thin Film Pt100 sensors (as small as 3.2mm x 1.6mm x 0.7mm) allows for easy integration into various machinery and equipment. This miniaturization is crucial in modern manufacturing environments where space is often at a premium. Additionally, their ability to withstand harsh conditions, including exposure to chemicals and high humidity, makes them ideal for use in chemical processing plants and food production facilities.

The fast response time of Thin Film Pt100 sensors is particularly beneficial in processes that require rapid temperature adjustments. For instance, in plastic injection molding, where precise temperature control is essential for product quality, the quick response of these sensors enables more accurate and responsive heating systems.

Aerospace and Automotive Applications

The aerospace and automotive industries have embraced Thin Film Pt100 sensors for their exceptional performance under extreme conditions. In aerospace applications, these sensors are used in various systems, from engine monitoring to environmental control systems in aircraft cabins. Their ability to operate accurately across a wide temperature range (-200°C to +850°C) makes them suitable for both the frigid temperatures at high altitudes and the extreme heat near engines.

In automotive applications, Thin Film Pt100 sensors play a crucial role in engine management systems, exhaust gas temperature monitoring, and battery temperature control in electric vehicles. The sensors' vibration resistance (up to 40g) and impact resistance (up to 100g) ensure reliable performance in the high-vibration environment of a moving vehicle.

The sensors' compact size is particularly advantageous in these industries, where space and weight considerations are critical. Their small form factor allows for integration into tight spaces without compromising the overall design or adding significant weight to the vehicle or aircraft.

Medical and Scientific Research

In the medical field, Thin Film Pt100 sensors have found applications in a variety of equipment and devices. Their high accuracy (±0.01 Ω) and fast response times make them ideal for use in medical diagnostic equipment, where precise temperature measurements are crucial. For instance, these sensors are often used in blood analyzers, PCR machines, and incubators.

The sensors' ability to maintain accuracy over time, with long-term stability drift ≤ 0.04%, is particularly valuable in medical applications where consistent, reliable measurements are essential for patient care and research integrity.

In scientific research, Thin Film Pt100 sensors are used in a wide range of applications, from environmental monitoring to cryogenic experiments. Their wide temperature range and stability make them suitable for various research settings, from laboratories to field studies. The sensors' compatibility with standard measurement and control systems also facilitates easy integration into research setups.

Conclusion

In the battle of Thin Film vs Wire Wound Pt100 sensors, the Thin Film variant emerges as the superior choice for most modern applications. Its compact size, fast response time, excellent stability, and wide temperature range make it a versatile solution for diverse industrial, aerospace, automotive, and medical needs. While Wire Wound Pt100 sensors still have their place in certain high-temperature applications, the overall performance advantages of Thin Film Pt100 sensors make them the preferred option for engineers and designers seeking reliable, accurate temperature measurement solutions.

As technology continues to advance, we can expect further improvements in Thin Film Pt100 sensor technology, potentially expanding their capabilities and applications even further. For those looking to implement cutting-edge temperature measurement solutions in their projects or products, exploring the possibilities offered by Thin Film Pt100 sensors is highly recommended. To learn more about how these advanced sensors can benefit your specific application, don't hesitate to reach out to our team of experts at sales11@xatzd.com.