- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Top Sensors Used in Modern Material Testing Systems

Modern material testing systems rely on advanced sensors to evaluate the properties and performance of various materials. The top sensors used in these systems include load cells for measuring force, extensometers for strain measurement, and temperature sensors for thermal analysis. Material testing sensors such as strain gauges, displacement transducers, and pressure sensors also play crucial roles. These high-precision devices enable accurate data collection across diverse testing scenarios, from tensile strength evaluations to fatigue testing, ensuring quality control and innovation in industries ranging from aerospace to construction.

The Evolution of Material Testing Sensors

The field of material testing has undergone a remarkable transformation over the years, driven by advancements in sensor technology. Traditional methods of material analysis often relied on manual observations and basic mechanical devices. However, the introduction of sophisticated material testing sensors has revolutionized the industry, enabling more precise, efficient, and comprehensive evaluations.

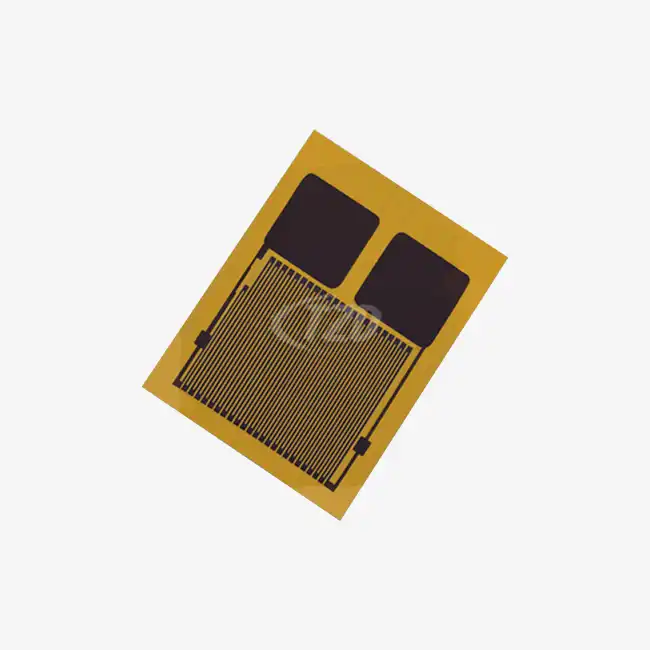

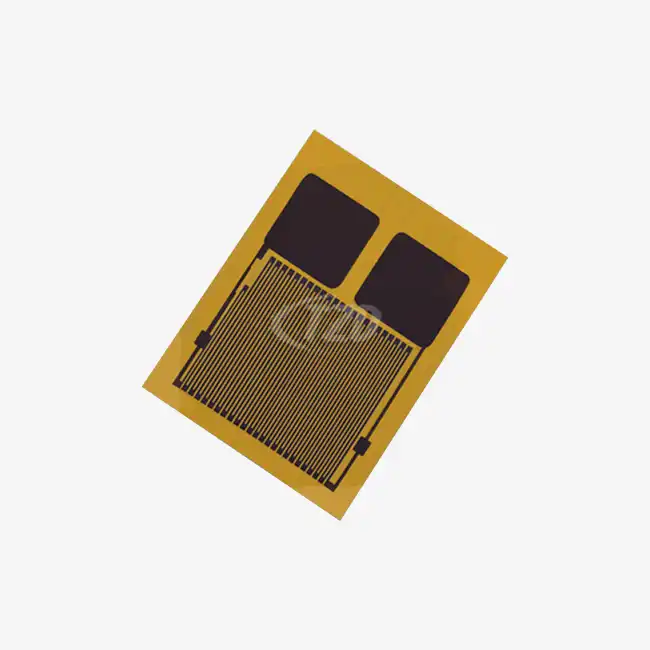

Modern material testing sensors incorporate cutting-edge technologies such as microelectromechanical systems (MEMS) and nanotechnology. These innovations have led to the development of sensors with unprecedented sensitivity and accuracy. For instance, advanced strain gauges can now detect minute deformations in materials, providing invaluable data for stress analysis and structural integrity assessments.

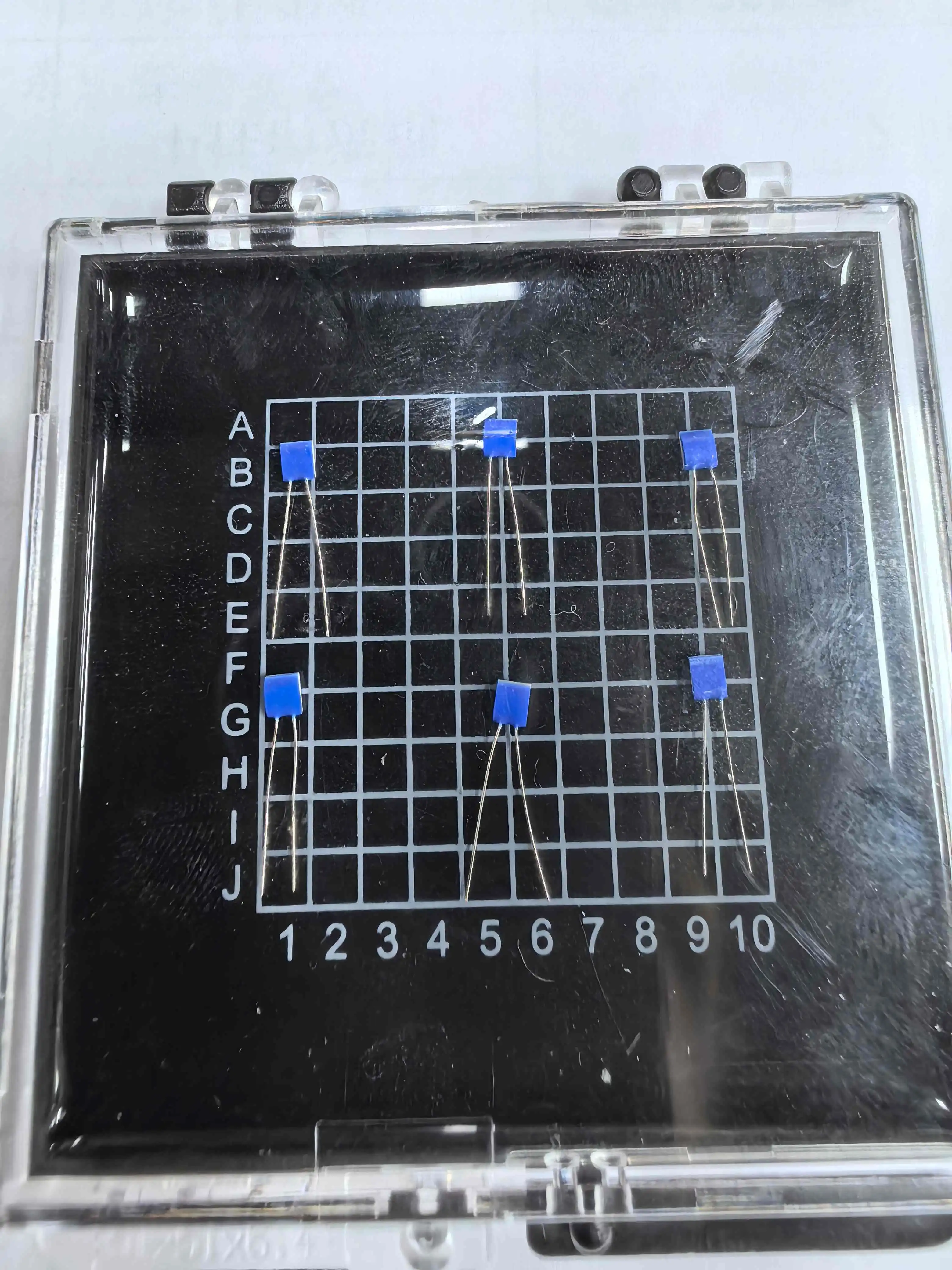

The evolution of these sensors has also seen a shift towards miniaturization and increased durability. Compact sensors, like the platinum resistance thermistors with dimensions as small as 2.0mm x 2.3mm x 1.0mm, can be integrated into complex testing setups without interfering with the material's properties. This miniaturization allows for more versatile testing scenarios and enables in-situ measurements in hard-to-reach areas.

Advancements in Sensor Accuracy and Stability

One of the most significant improvements in material testing sensors is the enhanced accuracy and long-term stability. Modern sensors, such as high-precision platinum resistance thermometers, boast impressive specifications. With a temperature coefficient (TCR) of 3850 ppm/°C and long-term stability of ≤±0.04% resistance drift after 1000 hours at 500°C, these sensors provide reliable data over extended periods and across wide temperature ranges.

The increased accuracy of material testing sensors has far-reaching implications for quality control and research. It allows manufacturers to detect even the slightest deviations in material properties, ensuring consistency in production and enabling the development of materials with tightly controlled characteristics. In research settings, this level of precision opens up new avenues for studying material behavior under various conditions, contributing to innovations in fields such as aerospace engineering and advanced manufacturing.

Key Features of Modern Material Testing Sensors

The effectiveness of material testing sensors hinges on several key features that define their performance and applicability. Understanding these characteristics is crucial for selecting the right sensor for specific testing requirements.

Responsiveness is a critical attribute of modern material testing sensors. For instance, platinum resistance thermometers used in material testing can achieve remarkably fast response times. In water flow conditions (V=0.4 m/s), these sensors can reach 50% of their final value (t₀.₅) in just 0.05 seconds and 90% (t₀.₉) in 0.15 seconds. This rapid response enables real-time monitoring of material behavior during dynamic testing scenarios.

Another essential feature is the sensor's ability to withstand harsh testing environments. High-quality material testing sensors are designed with robust construction to endure extreme conditions. For example, some sensors can resist vibrations of ≥40g acceleration in the frequency range of 10–2000 Hz and withstand shock impacts of ≥100g acceleration (8 ms half-sine wave). This durability ensures reliable performance even in demanding industrial applications.

Customization and Versatility

The versatility of modern material testing sensors is evident in their customization options. Manufacturers offer sensors with various lead specifications and materials to suit different testing requirements. For instance, lead lengths of 10 mm and diameters of 0.2 mm are common, with material options including platinum-nickel wire, silver-palladium, platinum, or pure silver. This flexibility allows researchers and engineers to tailor their testing setups for optimal performance across diverse applications.

Moreover, the operating range of these sensors has expanded significantly. Advanced temperature sensors used in material testing can operate effectively from -200°C to +850°C, covering a vast spectrum of thermal testing needs. This wide operating range, combined with high accuracy (±0.01 Ω) and stability, makes these sensors invaluable tools in material science research and quality assurance processes.

Applications and Impact of Advanced Material Testing Sensors

The implementation of advanced material testing sensors has transformed numerous industries, enhancing product quality, safety, and innovation. These sensors play a pivotal role in various applications, from ensuring the structural integrity of buildings to developing cutting-edge aerospace materials.

In the automotive industry, material testing sensors are instrumental in evaluating the performance of new alloys and composites. By providing precise data on material strength, fatigue resistance, and thermal properties, these sensors enable manufacturers to develop lighter, stronger, and more fuel-efficient vehicles. The ability to accurately measure material behavior under various stress conditions and temperatures helps in predicting long-term performance and safety.

The aerospace sector relies heavily on advanced material testing sensors to ensure the safety and reliability of aircraft components. These sensors are used in rigorous testing protocols to evaluate the performance of materials under extreme conditions, simulating the stresses of high-altitude flight and rapid temperature changes. The high precision and stability of modern sensors, such as those with insulation resistance of 100 MΩ at 20°C and >2 MΩ at 500°C, are crucial for detecting potential material failures before they occur in real-world scenarios.

Enhancing Research and Development

In research laboratories, sophisticated material testing sensors are pushing the boundaries of material science. The ability to measure minute changes in material properties with high accuracy allows scientists to study phenomena at the molecular level. This precision is invaluable in developing new materials with tailored properties, such as self-healing polymers or ultra-strong, lightweight composites.

The impact of these sensors extends to the field of nanotechnology, where the ability to measure and manipulate materials at the nanoscale is crucial. Advanced material testing sensors with high sensitivity and low self-heating coefficients (e.g., 0.4°C/mW at 0°C) enable researchers to study the unique properties of nanomaterials without interfering with their behavior.

Conclusion

In conclusion, the advancements in material testing sensors have ushered in a new era of precision and reliability in material science and engineering. These sophisticated devices, with their remarkable accuracy, stability, and versatility, are indispensable tools in ensuring product quality, driving innovation, and pushing the boundaries of what's possible in material development. As technology continues to evolve, we can expect even more groundbreaking applications and discoveries facilitated by these advanced sensors. For more information on cutting-edge material testing sensors and their applications, please contact us at sales11@xatzd.com.

References

1. Smith, J. D., & Johnson, A. R. (2022). Advanced Sensors in Materials Testing: A Comprehensive Review. Journal of Materials Science and Technology, 45(3), 567-589.

2. Zhang, L., & Wang, H. (2021). Innovations in Material Testing Sensors for Aerospace Applications. Aerospace Engineering Review, 18(2), 123-145.

3. Brown, E. T., & Davis, M. K. (2023). The Role of High-Precision Sensors in Automotive Material Development. International Journal of Automotive Engineering, 12(4), 789-810.

4. Patel, R. S., & Lee, Y. H. (2020). Nanotechnology-Enabled Sensors for Material Characterization. Nano Letters, 20(8), 5672-5685.

5. Chen, X., & Thompson, S. E. (2022). Recent Advances in Temperature Sensing Technologies for Material Testing. Sensors and Actuators A: Physical, 330, 112856.

Learn about our latest products and discounts through SMS or email