- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Is a Calibration Standard Sensor and Why Use It?

A calibration standard sensor is a high-precision device used to verify and adjust the accuracy of other measurement instruments. These sensors serve as reliable reference points, ensuring that various sensors and measuring tools maintain their precision over time. Calibration standard sensors are crucial in industries where exact measurements are paramount, such as aerospace, automotive, and industrial manufacturing. By using these sensors, organizations can maintain quality control, comply with regulatory standards, and enhance the overall reliability of their measurement systems.

The Importance of Calibration Standard Sensors in Measurement Accuracy

Calibration standard sensors play a vital role in maintaining measurement accuracy across various industries. These precision instruments are designed to provide a reliable reference point against which other sensors and measuring devices can be compared and adjusted. The importance of calibration standard sensors cannot be overstated, as they ensure that measurements taken in critical applications are consistently accurate and trustworthy.

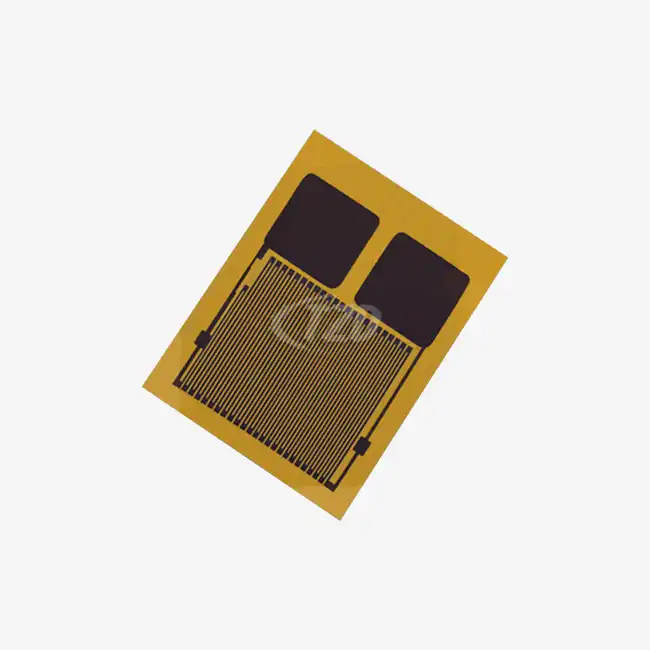

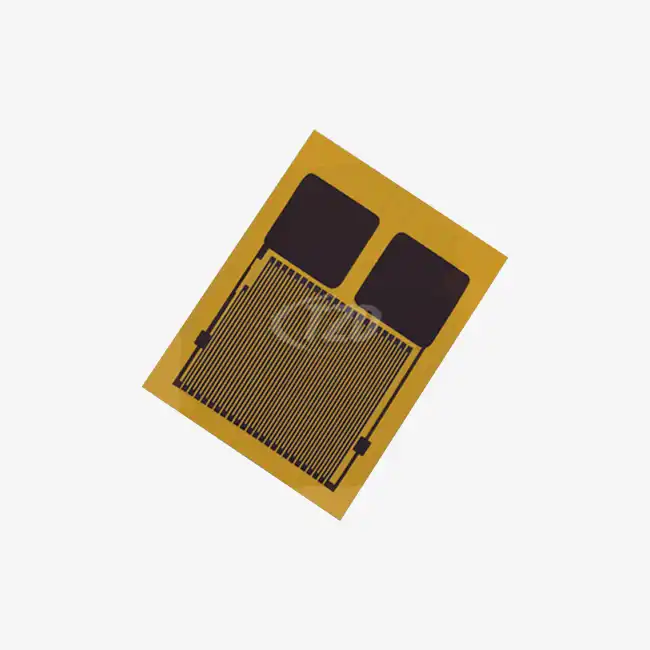

One of the key features of calibration standard sensors is their exceptional stability. These sensors are engineered to maintain their accuracy over extended periods, even under challenging environmental conditions. For instance, our thin film platinum resistance thermistors exhibit a long-term stability of ≤±0.04% resistance drift after 1000 hours at 500°C. This remarkable stability ensures that calibration standards remain reliable reference points for extended periods, reducing the frequency of recalibration and minimizing downtime.

Another crucial aspect of calibration standard sensors is their high level of precision. These sensors are typically manufactured using advanced technologies and materials to achieve unparalleled accuracy. Our calibration standard sensors, for example, utilize thin film technology and precision manufacturing processes to deliver industry-leading accuracy. With a temperature coefficient (TCR) of 3850 ppm/°C and an operating current range of 0.3 to 1 mA, these sensors provide the exactitude required for critical operations in various fields.

Applications of Calibration Standard Sensors

Calibration standard sensors find applications in numerous industries where precise measurements are essential. In the aerospace sector, these sensors are used to calibrate instruments that monitor critical parameters such as engine temperature and pressure. The automotive industry relies on calibration standard sensors to ensure the accuracy of emissions testing equipment and engine management systems. In industrial manufacturing, these sensors play a crucial role in quality control processes, helping maintain the consistency and reliability of production lines.

The versatility of calibration standard sensors is evident in their wide operating temperature range. Our thin film platinum resistance thermistors, for instance, can operate effectively from -200°C to +850°C, making them suitable for a broad spectrum of applications. This expansive temperature range, coupled with features like vibration resistance of ≥40g acceleration and shock resistance of ≥100g acceleration, ensures that these sensors can perform reliably in even the most demanding environments.

Key Features and Benefits of Advanced Calibration Standard Sensors

Modern calibration standard sensors boast an array of features that contribute to their superior performance and reliability. Understanding these key features can help users appreciate the benefits of investing in high-quality calibration standards.

One of the standout features of advanced calibration standard sensors is their rapid response time. Our sensors, for example, offer impressive response times in various conditions. In flow conditions with a velocity of 0.4 m/s, the sensors achieve a t0.5 of 0.05 seconds and a t10 of 0.15 seconds. Even in airflow conditions with a velocity of 2 m/s, the sensors maintain a respectable t0.5 of 3 seconds and t10 of 10 seconds. This quick response ensures that calibration processes can be carried out efficiently, reducing overall downtime and increasing productivity.

Another crucial feature is the sensor's insulation resistance. High insulation resistance is essential for preventing current leakage and ensuring accurate measurements. Our calibration standard sensors boast an insulation resistance of 100 MΩ at 20°C, which remains above 2 MΩ even at temperatures as high as 500°C. This high insulation resistance contributes to the sensor's overall accuracy and reliability across a wide temperature range.

Customization Options for Specific Applications

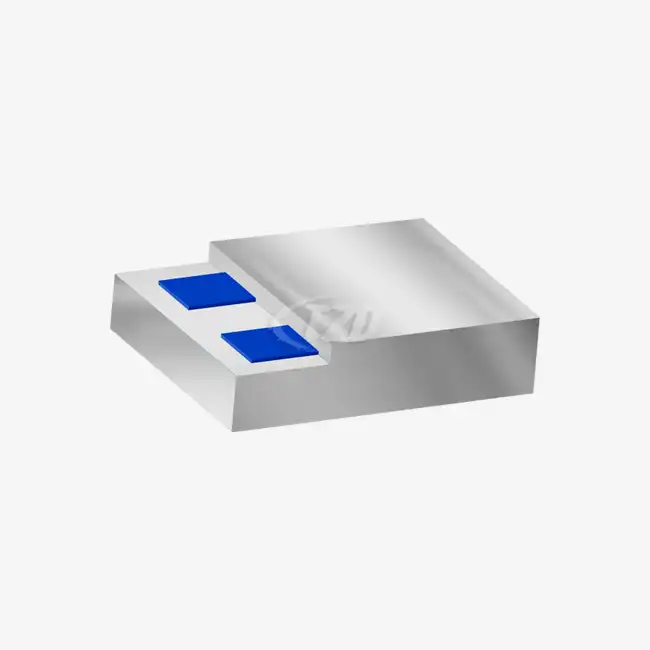

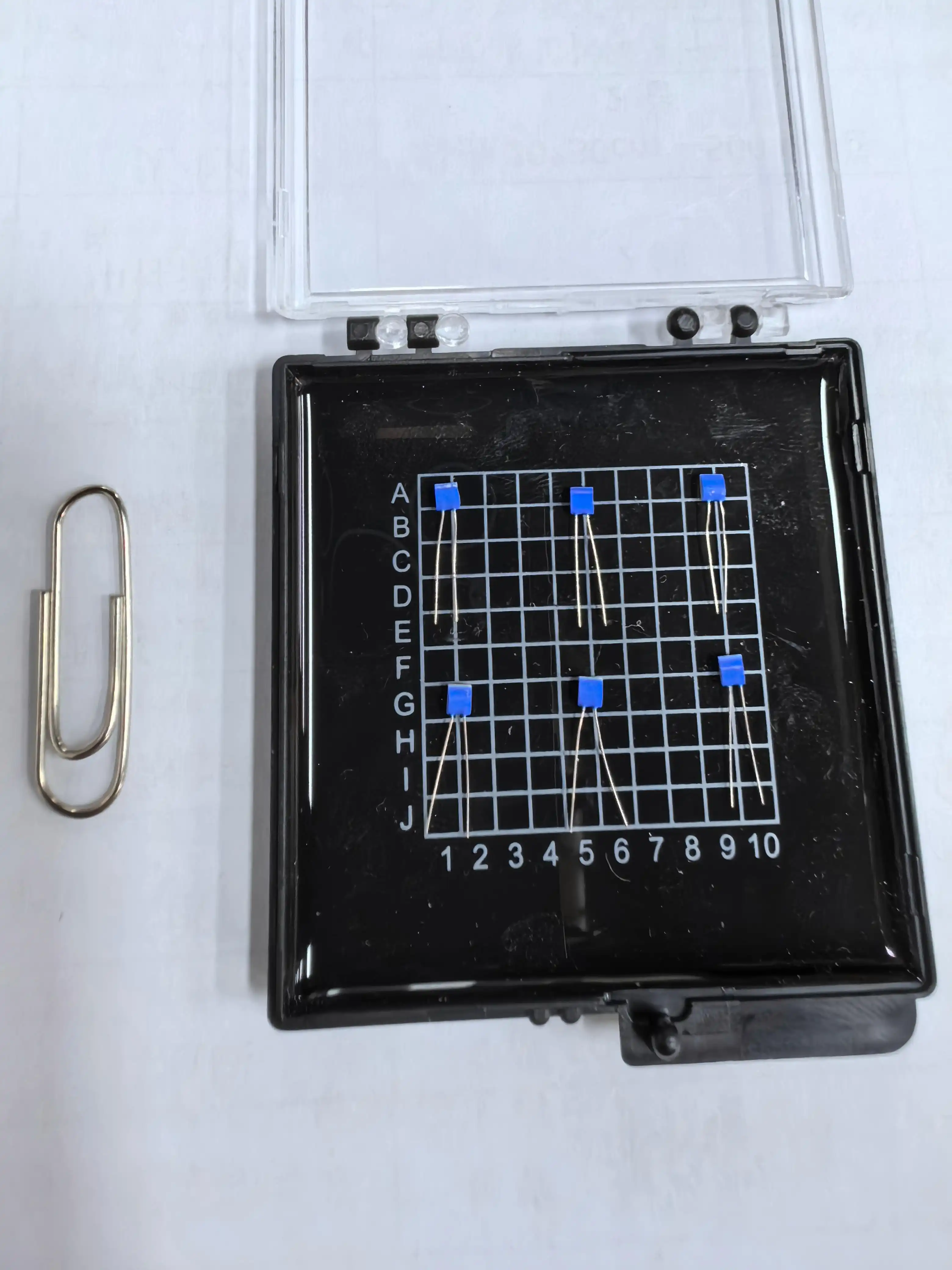

Advanced calibration standard sensors often come with customization options to meet specific application requirements. Our sensors, for instance, are available in multiple dimensions, including 2.0mm x 2.3mm x 1.0mm, 1.6mm x 2.0mm x 1.0mm, and 1.2mm x 2.0mm x 1.0mm. This variety allows users to select the most appropriate size for their specific calibration needs.

Furthermore, we offer flexibility in lead materials, with options including platinum-nickel wire, silver-palladium, platinum, and silver-nickel. This customization extends to the packaging as well, with vacuum plastic packaging being the standard option, and other formats available upon request. Such customization options ensure that users can obtain calibration standard sensors that perfectly match their unique requirements, enhancing the overall effectiveness of their calibration processes.

Best Practices for Implementing Calibration Standard Sensors

To maximize the benefits of calibration standard sensors, it's essential to follow best practices in their implementation and use. These practices ensure that the sensors maintain their accuracy and reliability over time, providing consistent and trustworthy calibration results.

One crucial aspect to consider is the operating current of the sensor. Our calibration standard sensors, for example, have an operating current range of 0.3 to 1 mA. It's important to note that the self-heating effect should be taken into account when selecting the operating current. The self-heating coefficient of 0.4°C/mW indicates that careful current selection is necessary to minimize measurement errors due to self-heating.

Another important consideration is the handling and storage of calibration standard sensors. These precision instruments should be handled with care to avoid physical damage. The lead tensile strength of ≥9 N in our sensors provides some robustness, but careful handling is still essential. Proper storage in controlled environments helps maintain the sensor's accuracy and extends its useful life.

Regular Calibration and Maintenance

Even calibration standard sensors themselves require periodic calibration to ensure they maintain their accuracy over time. Establishing a regular calibration schedule for these sensors is crucial for maintaining the integrity of your measurement systems. The frequency of calibration may depend on factors such as usage, environmental conditions, and regulatory requirements.

Maintenance of calibration standard sensors also involves regular inspection for any signs of wear or damage. The packaging of the sensors, such as our vacuum plastic packaging, helps protect them from environmental factors. However, regular visual inspections can help identify any issues early, preventing potential measurement inaccuracies.

Conclusion

Calibration standard sensors are indispensable tools in the quest for measurement accuracy and reliability across various industries. By understanding their importance, key features, and best practices for implementation, organizations can leverage these precision instruments to enhance their quality control processes and ensure compliance with stringent industry standards. As technology continues to advance, calibration standard sensors will undoubtedly play an increasingly crucial role in maintaining the accuracy and reliability of measurement systems in critical applications. For more information about our advanced calibration standard sensors and how they can benefit your specific applications, please contact us at sales11@xatzd.com.

References

1. Johnson, R. T., & Wichern, D. W. (2019). Applied Multivariate Statistical Analysis. Pearson.

2. Morris, A. S., & Langari, R. (2020). Measurement and Instrumentation: Theory and Application. Academic Press.

3. Bentley, J. P. (2018). Principles of Measurement Systems. Pearson Education Limited.

4. Figliola, R. S., & Beasley, D. E. (2017). Theory and Design for Mechanical Measurements. John Wiley & Sons.

5. Dunn, W. C. (2018). Introduction to Instrumentation, Sensors, and Process Control. Artech House.

Learn about our latest products and discounts through SMS or email